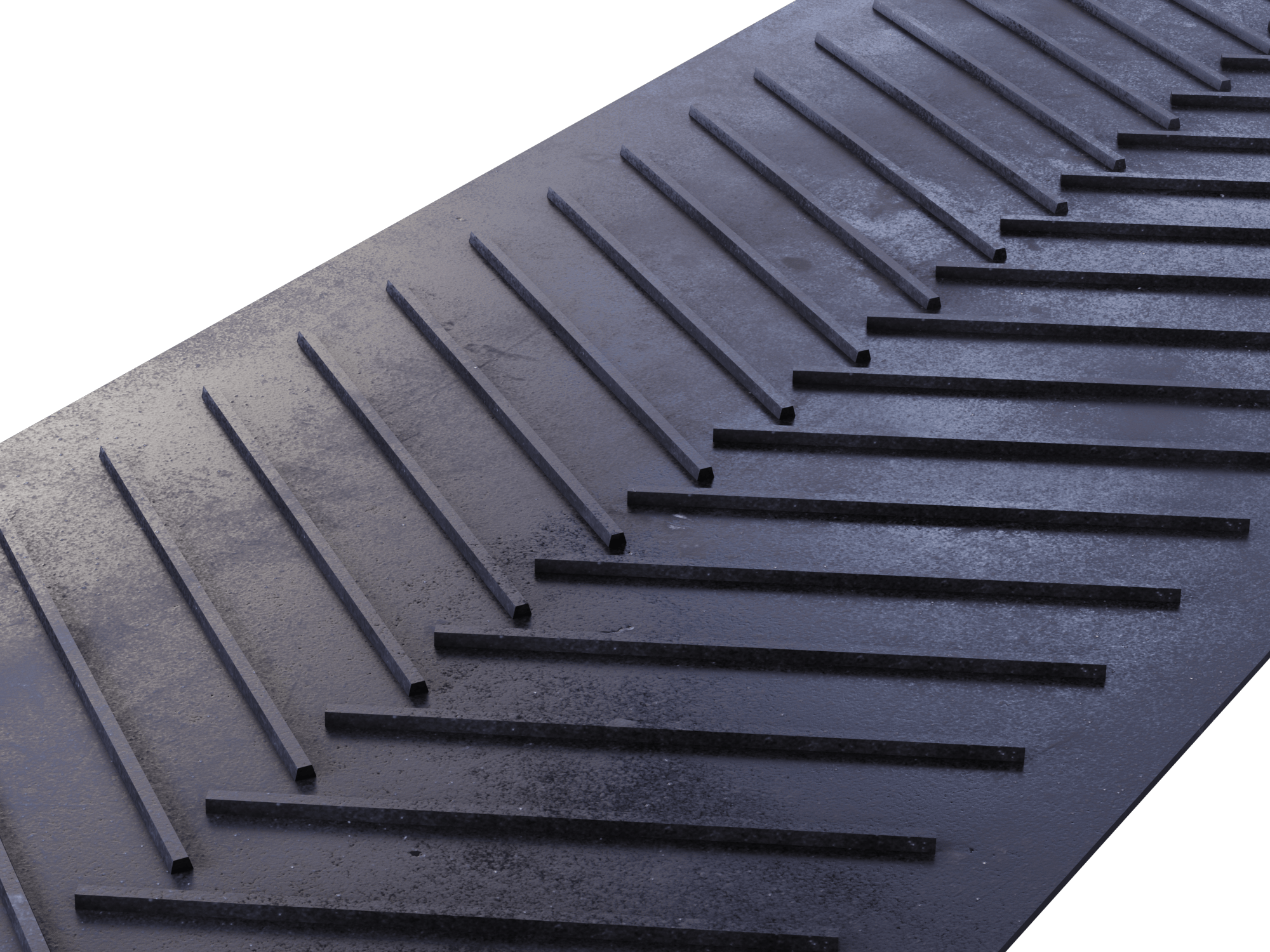

Replacement Chevron Cleated Conveyor Belts

Steep inclines for moving bulk materials in multiple industries such as recycling, farming, mining, refineries, quarries and sand pits, crushing and screening

Replacement Chevron Conveyor Belt Overview

Fluent Conveyors offers a wide range of premium, well-constructed chevron conveyor belts at a market competitive price. Chevron conveyor belts come in a variety of cleat patterns including: open chevron, closed chevron, herringbone, u-shaped, cleat top, steep climb and more to meet the requirements of a wide variety of material applications.

We offer over 100 different cleat patterns with various compound options. The more common requests include the following:

- Rubber

- Neoprene

- Nitrile (FDA/USDA)

- SBR

- Butyl

- PVC

- Polyurethane

Chevron belting comes in either PVC or rubber with cleat heights ranging from 1/8” to 2” high. There are options for oil resistant, food grade, fire retardant and chemical resistant belts as well.

If you need help getting the exact measurement, please click here for instance access to our free resource center!

Fluent Conveyors offers 100s of chevron patterns in various heights and forms to meet nearly any specifications or needs. These patterns can be full width or repeating and are designed to be rugged and last in harsh environments.

Our internal process and team wants to make sure we take our time to get you the exact belt your application requires whether its reinforced rubber belting, a different cleat pattern to stop roll back or a thicker belt. We don't want to just be your belt supplier but a long-term partner and resource to you and your team.

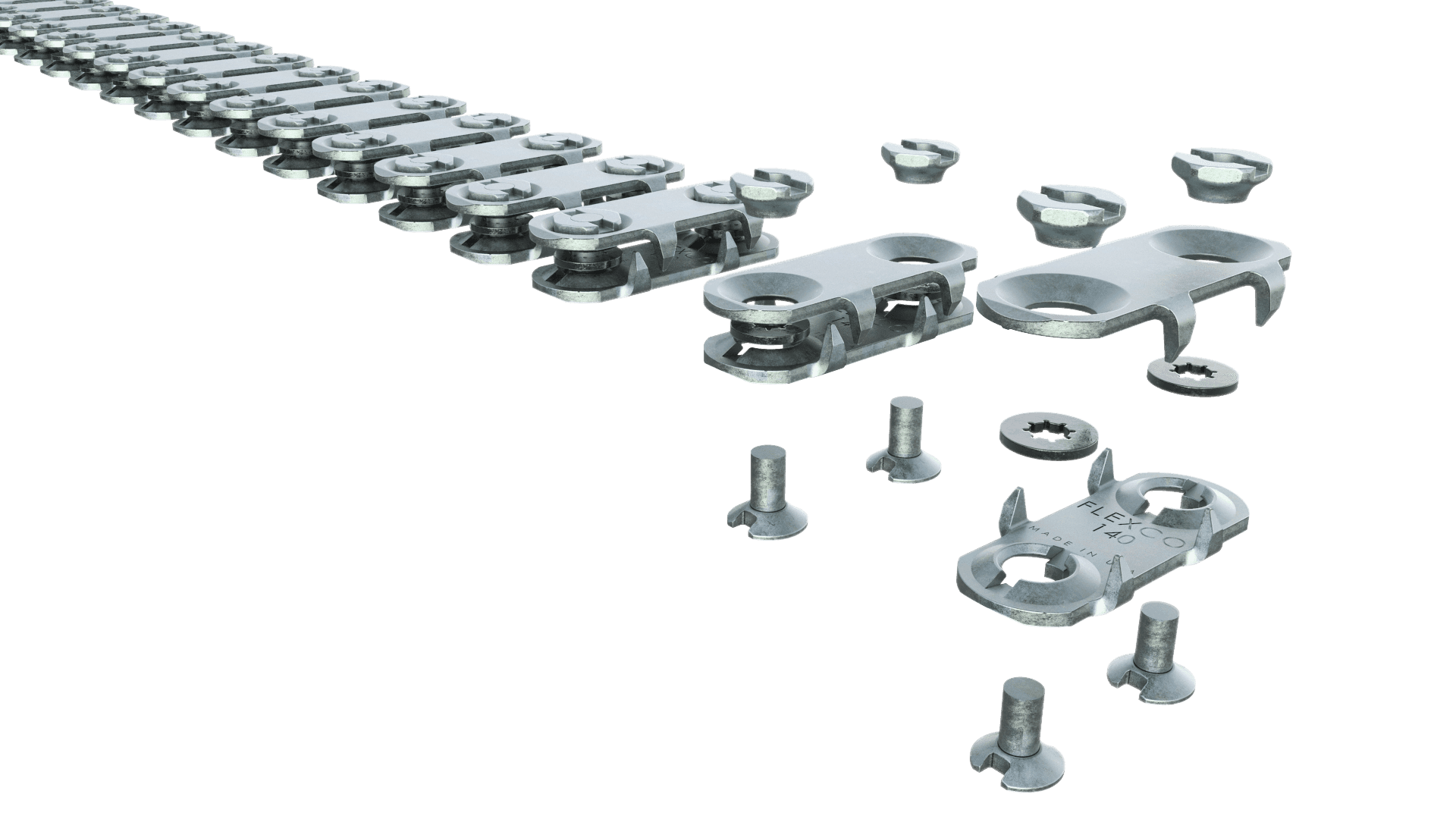

Fluent Conveyors offers many different splices to fit your needs and specifications. We offer stainless steel mechanical splices such as alligator splicing, rivet plate, rivet hinge, bolt plate and bolt hinge splicing. Fluent Conveyors also offers our belts with vulcanized splices. We offer longitudinal vulcanized splice, diagonal vulcanized splice, finger vulcanized splice and step vulcanization and more.

Preventative Maintenance

The Fluent Chevron Belts, like all slider bed conveyor belts, require up-front adjustments and maintenance to ensure the longevity of the belt and conveyor components.

Core adjustments and maintenance:

-Visual inspection (all cleats, splicing)

-General removal of debris

-Maintain belt tension & tracking

**If you have additional questions or need help with anything on your conveyor, please visit our help section below or give our engineering team a call.

Detailed & Customized Mechanical Engineering

FLUENT CONVEYOR DESIGN GUIDELINES

Fluent Conveyors Chevron conveyor belts are designed with cutting edge software to be ahead of the curve. Giving you an edge above the rest. Fluent Conveyors uses premium 3D CAD software and has our belts manufactured to industry leading tolerances and standards to guarantee premium quality conveyor belts. After completion of a design, the engineering team releases to quality assurance, allowing secondary engineers to validate critical dimensions, calculations and manufacturability. After initial and secondary engineering approvals, belts are released to the manufacturing facility by the lead manufacturing engineer. Our experts only approve the highest caliber work to ensure you’re working with nothing but the best.

FLUENT ROLLER CHAIN BELT MANUFACTURING GUIDELINES

Fluent Conveyor Belts are built in innovative facilities to equip you with the best product possible. With all the industry leading equipment and processes, Fluent Conveyors production team has over 100 years of combined experience paired with a facility of more than 85,000 square feet. The core facility has a paint booth, 40,000 square feet of dedicated assembly, 6 – welding stations, CNC fabrication equipment, 10 – overhead cranes and more. Parts are cut/machined on CNC Routed machines ensuring you’re working with smart, flawless machinery.

CONVEYOR TESTING OVERVIEW

All conveyor belts are delivered to you ready for hard work. Assembled and released to a detailed quality assurance checklist to make sure your machinery can hit the ground running. This includes key validations such as sub-assembly QC, visual inspection and dimension verification. Making sure your new conveyor belt is set up for long term success.

SHIPPING OVERVIEW

We ship the smartest way possible, to make your job easy. Fluent Conveyors Product shipments are carefully planned in CAD software to be loaded in an organized, space saving, and safe manner ensuring that all products arrive on-site the same as when they left our facility. Loose items are boxed and marked, assembled parts and components tightened to endure the rigors of freight and shipping. We’re here to make sure every step of the process is seamless.

- Standard Cleat Top

- Mini Cleat Top

- Multi-Chev

- The Big Horn

- The Bull Horn

- Fabclimb

- Fablift

- Longhorn

- 1 Ply

- 2 Ply

- 3 Ply

- 4 Ply

- Additional options upon request

- Rivet plate & hinged

- Bolt Hinged & plate

- Alligator Hinged & clips

- Vulcanized

- Mining

- Recycling

- Food Processing

- Bio-Fuel

- Cardboard (OCC) Recycling

- Carpet Recycling

- E-Waste Recycling

- Glass Recycling

- Manufacturing

- Mining

- Mixed Solid Waste (MSW)

- Paper Recycling

- Plastics Recycling

- Single Stream Recycling

- Textile Recycling

- 3-7 Plastic

- Aluminum

- Bagasse

- Beets

- Bio-Waste

- Bulk Materials

- Coal, Dirt (Earth)

- E-Waste, Foam

- Glass

- Grain

- Gravel

- Hay

- HDPE

- Iron Ore

- LDPE

- Medical Waste

- Mixed Paper

- MSW

- Non-Ferrous

- OCC

- Paperboard

- PET

- Potatoes

- Rubber

- Single Stream

- Stover

- Sugar

- Textiles

- Tissue Paper

- Rubber

- Neoprene

- Nitrile (FDA/USDA)

- SBR

- Butyl

- PVC

- Polyurethane

As well as producing bespoke conveyor systems, we also supply custom replacement belts and parts to ensure no client sees their assembly line stay offline for an extended period of time. From replacement motors to sprockets, everything is covered if a client comes across a failing element of their conveyor system.

Sadly, it’s inevitable your clients will face some type of issue with their conveyor system at some point. Even with Fluent Conveyors’ best equipment in place, conveyors are going to suffer from wear and tear due to their demanding nature. However, being able to offer a solution at any time will be appreciated by your clients.

Are You Looking For A Easy & Seamless Way To Order Belting?

Our Process Is Typically Very Lean & Detailed! We Prefer Not To Waste Our Customers Time!

Please Contact Us If You Want Help On Your Conveyor Belt & You Are Comfortable With:

- Price Can Range For Each Belt From $500 - $10,000+

- Lead Time of 2 Days – 4 Weeks (Depending on belt specs, splice requirements etc)

- You have visited our resource center and have all the required dimensions

- Have the ability to review & sign approval drawings

- 100% pre-payment before manufacturing. These are made to order per your specifications & can't be returned

-

How to replace a slider bed conveyor belt?

Fluent has drawings and videos depicting the belt replacement process for our standard equipment. We recommend you look at these even for replacing other belts on other manufacturers equipment. Please give us a call if you cannot find the information you need.

-

How to adjust a conveyor belt?

Conveyor belt tensioning is done at the take-up. Tracking can be done at the head, the tail, the take-up and the carry and return rollers. Fluent has drawings and videos on how to tension and track belts on our standard slider bed and trough idler conveyors. If you need more help then please contact fluent conveyors.

-

How much weight can a chevron cleated conveyor belt hold?

There are many different constructions for the conveyor belt. What type of machine this is going on and the tonnages as well as speeds all can vary this answer? Please call fluent conveyors and we can help you find the belt that is right for your application.

-

How often should a conveyor belt be replaced?

Conveyor belt life can vary significantly depending on the application. Fluent recommends replacing your belt when any of the following is present. 1. Weave from the carcass is fraying out of the belt. 2. There are worn through holes or tears in the belt. 3. The cleats or side walls have ripped off the belt. 4. The belt has stretched to the point where you can no longer add tension with your take up or the belt is becoming difficult to keep tracked due to uneven elongation.

-

How to replace a slider bed conveyor belt?

Fluent has drawings and videos depicting the belt replacement process for our standard equipment. We recommend you look at these even for replacing other belts on other manufacturers equipment. Please give us a call if you cannot find the information you need.

-

How to adjust a conveyor belt?

Conveyor belt tensioning is done at the take-up. Tracking can be done at the head, the tail, the take-up and the carry and return rollers. Fluent has drawings and videos on how to tension and track belts on our standard slider bed and trough idler conveyors. If you need more help then please contact fluent conveyors.

-

How much weight can a chevron cleated conveyor belt hold?

There are many different constructions for the conveyor belt. What type of machine this is going on and the tonnages as well as speeds all can vary this answer? Please call fluent conveyors and we can help you find the belt that is right for your application.

-

How often should a conveyor belt be replaced?

Conveyor belt life can vary significantly depending on the application. Fluent recommends replacing your belt when any of the following is present. 1. Weave from the carcass is fraying out of the belt. 2. There are worn through holes or tears in the belt. 3. The cleats or side walls have ripped off the belt. 4. The belt has stretched to the point where you can no longer add tension with your take up or the belt is becoming difficult to keep tracked due to uneven elongation.