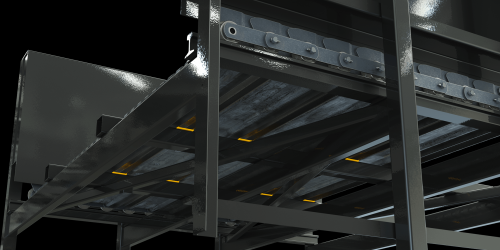

Hinged Steel Roller Chain Replacement Conveyor Belts

Ideal for flat or incline conveying of heavier material found in the following industries: recycling, solid waste, metal manufacturing, foundries and more.

Hinged Steel Roller Chain Conveyor Belt Overview

Fluent Conveyors Hinged Steel Belts are a great solution for medium duty conveyance. These belts are best suited for low to moderate speed and made to handle repetitive impacts and abrasive materials. Our formed piano hinged design are made from mild steel with medium carbon sidebars. All rods are premium alloy steel. Fluent offers ¼” pans and 3/16” pans in both 6” pitch and 9” pitch options.

The Fluent Conveyors hinged steel belt offers options for bearings that reduce overall friction and extend chain life. The hinged steel pans can be formed with dimples (better grip), perforated (drainage) or both.

Our hinged steel belting is found in a wide variety of industries including waste, recycling, mining, stamping, automotive, manufacturing and more. .

Engineering Specs

Fluent Conveyors belts are engineered with industry leading 3D CAD. The manufacturing team has over 50 years of combined experience on conveyor belts and understand the most complex applications to ensure the correct belt is always used. All replacement belts are engineered closely with the production team to ensure the processes from engineering to manufacturing meets tight tolerances, QA validation and project deadlines.

Manufacturing Specs

Fluent Conveyors belts have been tested, validated and approved to meet the quality tolerances our engineering team requires. The production team has over 50 years of combined experience paired with a new technology, validated core processes and a great quality assurance process that ensures all belt specs meet approval drawings and application requirements.

The Fluent Conveyors hinged steel conveyor belts only require standard maintenance to guarantee a trouble free operation. These belts come pre-tensioned and run for over two days prior to shipment to ensure they fit correctly and run smoothly.

Core adjustments and maintenance:

- Visual inspection (belt, damage, pan issues). This inspection is important to ensure that all of the components on your conveyor will continue to function as designed. Further protecting the other components and increasing the overall life of your machine.

- General removal of debris (chainways are clear and rollers/chain bars are free of debris). Keeping your conveyor clean is imperative to remove the risk of jams or potential failure.

- Auto Chain Oilers are full and functioning. Keeping your chain properly oiled is imperative to the function and longevity of your conveyor. A properly oiled chain significantly reduces running friction (saving you energy) and can last more than twice as long as an under oiled chain.

- Maintaining proper chain tension. This should be done through periodic visual checks to ensure the chain is not loos enough to slip over teeth on the drive sprockets, but also not so tight as to add friction and resistance to the system.

**If you have additional questions or need help with anything on your conveyor, please visit our help section below or give our engineering team a call.

Collaborate

At Fluent Conveyors, we look for partners over clients. Your success is our success. Every step along the way, through dynamic collaboration, we ensure high-end experience from pre-sales engineering to install.The process starts with a detailed system design meeting in which fluent sales and engineering staff complete a pre-project kick off call with our customer to gather all necessary info and gain a detailed understanding of their specific needs. The Engineering team designs a unique solution while working with each customer to ensure accuracy and detailed approval drawings. Ensuring your vision comes to life.

Create

Our open creative process ensures you’re always in the driver’s seat. We blend technical expertise with visionary thinking to ensure your expectations are not only met, but surpassed. Fluent Conveyors uses leading edge 3D CAD and automation tools to ensure a process that puts the customer first, provides a speedy turnaround time, error free engagement and a better overall customer experience. End result: engineered product for your specific application type and unique needs delivered in hours – not days or weeks.

Convey

Our processes ensure 100’s of customers across the World precise, efficient, and smooth operations. Each conveyor is tested, validated and approved to verify structural and mechanical operability. It’s just that simple.

.38 - 1.0 ID x .55 - 1.38 OD Long 1018 solid, machined bushing. Carburized, hardened RC55-60, press fit into inner side bars.

C 3” x 5# up C 6” x 8.2# heavy duty channel every other pitch

Standard 2” x ¼” thick C1045 precision die-punched sidebar. Additions include 2” x 3/8” thick and 2.5” x ½” thick. 1” x 5/32” thick on the smaller pitches

¼” or 3/8” thick angle cleats in 2”, 3” or 4” high options. Bar cleats available

Fluent Conveyors offers 1/8”, 3/16” or ¼” custom formed hinged pans. Max widths up to 120” wide.

Custom number of rows, ¼”, 3/8”, ½”, 5/8”, ¾” and 1” thick formed impact shoes every other pitch

Easy maintenance of chain and to secure the rods to the rollers. Solid locking pins available.

Flanged and hardened steel rollers in 1-9/16”, 1- ¾”, 2-1/16”, 3”, 3 ½”, 4” and 5” diameter options.

C1045 CRS 3/4” diameter. Pins end milled flat to lock into outer side bar drilled for 1/4”x1” solid locking pin.

1-1/2”, 2- ½”, 3”, 4” & 6” high precision die formed interlocking off set wing 1/8” - 1/4” thick wing fully mig welded to hinge to prevent scrap build up.

Engineered structural tubing thicker wall than other conveyor belt manufacturers. While still being interchangeable, it offers superior wear characteristics, and extends the entire width of the belt.

Detailed & Customized Mechanical Engineering

FLUENT CONVEYOR DESIGN GUIDELINES

Fluent Conveyors Hinged Steel Roller Chain conveyor belts are designed with cutting edge software to be ahead of the curve. Giving you an edge above the rest. Fluent Conveyors uses premium 3D CAD software and has our belts manufactured to industry leading tolerances and standards to guarantee premium quality roller chain conveyor belts. After completion of a design, the engineering team releases to quality assurance, allowing secondary engineers to validate critical dimensions, calculations and manufacturability. After initial and secondary engineering approvals, belts are released to the manufacturing facility by the lead manufacturing engineer. Our experts only approve the highest caliber work to ensure you’re working with nothing but the best.

FLUENT ROLLER CHAIN BELT MANUFACTURING GUIDELINES

Fluent Conveyors Roller Chain Conveyor Belts are built in innovative facilities to equip you with the best product possible. With all the industry leading equipment and processes, Fluent Conveyors production team has over 100 years of combined experience paired with a facility of more than 85,000 square feet. The core facility has a paint booth, 40,000 square feet of dedicated assembly, 6 – welding stations, CNC fabrication equipment, 10 – overhead cranes and more. Parts are cut/machined on CNC Routed machines and bent on CNC Brakes for the best in industry tolerances. Every weld is tacked and re-measured for accuracy then completed by the staff of certified welders. Ensuring you’re working with smart, flawless machinery.

CONVEYOR TESTING OVERVIEW

All conveyor belts are delivered to you ready for hard work. Assembled and released to a detailed quality assurance checklist to make sure your machinery can hit the ground running. This includes key validations such as; weld examination, sub-assembly QC, visual inspection and dimension verification. Making sure your new conveyor belt is set up for long term success.

SHIPPING OVERVIEW

We ship the smartest way possible, to make your job easy. Fluent Conveyors Product shipments are carefully planned in CAD software to be loaded in an organized, space saving, and safe manner ensuring that all products arrive on-site the same as when they left our facility. Loose items are boxed and marked, assembled parts and components tightened to endure the rigors of freight and shipping. We’re here to make sure every step of the process is seamless.

- 6”

- 12”

- 18”

- 24”

- 30”

- 36”

- 48”

- 60”

- 72”

- 84”

- 96”

- 108”

- Custom widths from 36” up to 120” width with all increments within that range. The 2.5” pitch can go in 3” width increments.

- 2”

- 3”

- 4”

- ¼” – 3/8” thick angle

- Flat bar cleats also available.

- 2-1/2 inch

- 4 Inch

- 6 Inch

- 9 Inch

- 1/8”

- 3/16”

- 1/4 thick”

- 1-1/2”

- 2-1/2”

- 4”

- 6”

- 6,000#

- 9,000#

- 13,000#

- 14,000#

- 25,000#

- 1/4”

- 3/8”

- 1/2”

- .39 inside diameter x .55 outside diameter

- .5 inside diameter x .69 outside diameter

- 1.0 inside diameter x .1.38 outside diameter

- 3/8”

- ¾

- 1”

- 1-9/16”

- 1- ¾”

- 2 1/16”

- 3”

- 4”

- 5”

- C-channel

- no wings

- top impact pads

- inverted angle

- bar cleats

As well as producing bespoke conveyor systems, we also supply custom replacement belts and parts to ensure no client sees their assembly line stay offline for an extended period of time. From replacement motors to sprockets, everything is covered if a client comes across a failing element of their conveyor system.

Sadly, it’s inevitable your clients will face some type of issue with their conveyor system at some point. Even with Fluent Conveyors’ best equipment in place, conveyors are going to suffer from wear and tear due to their demanding nature. However, being able to offer a solution at any time will be appreciated by your clients.

Are You Looking For A Easy & Seamless Way To Order Hinged Steel Roller Chain Belting?

Our Process Is Typically Very Lean & Detailed! We Prefer Not To Waste Our Customers Time!

Please Contact Us If You Want Us To Help & You Are Comfortable With The Following:

- Price Can Range For Each Belt From $20,000 - $100,000+

- Lead Time of 5 Weeks – 8 Weeks + (Depending on belt specs, splice requirements etc)

- You have visited our resource center and have all the required dimensions

- Have the ability to review & sign approval drawings

- 50% down, 40% 2 weeks prior to shipment, 10% net 30 post install

-

How do I track my roller chain belt?

Roller chain belts should be self-tracking for the most part. If you are having trouble with the tracking of a roller chain belt, we recommend that you contact the manufacturer of that conveyor immediately. There are several things that could cause this problem. Please start by inspecting your conveyor for any Jam or debris that could be impeding the flow of the belt/material. Next ensure that your take up is in the same position on both sides (this is best done by measuring with a tape measure). Also check that your head shaft is sitting level to the conveyor and that all bearings are mounted properly leaving the shaft perpendicular to the belt travel. If you still have not found the problem, then it is time to go over your conveyor from tail to head and ensure that it is level across the width of the conveyor at every seem in the sections. A twisting conveyor frame can cause tracking issues.

-

How to support a chain conveyor?

Fluent Conveyors ships all our roller chain conveyors with welded on rigging points. It is recommended that you use these for all lifting and rigging. The pit sections can be strapped around the rail. Fluent Conveyors designs all our conveyors with supports and support attachment locations. Please consult your install drawings to confirm that you are using the correct locations.

-

What to do with old conveyor belts?

Fluent Conveyors recommends that you recycle all old conveyor belts.

-

How long will it take to deliver a replacement hinged steel conveyor belt?

Fluent Conveyors hinged steel conveyor belts normally take 4-6 weeks plus shipping for belts that follow industry standard specifications. Please contact our sales team and we can get started with you immediately.

Factors that would speed this up or slow it down include current production schedule, thickness of belting, additional options and complexity of the specific belt.

-

How do I track my roller chain belt?

Roller chain belts should be self-tracking for the most part. If you are having trouble with the tracking of a roller chain belt, we recommend that you contact the manufacturer of that conveyor immediately. There are several things that could cause this problem. Please start by inspecting your conveyor for any Jam or debris that could be impeding the flow of the belt/material. Next ensure that your take up is in the same position on both sides (this is best done by measuring with a tape measure). Also check that your head shaft is sitting level to the conveyor and that all bearings are mounted properly leaving the shaft perpendicular to the belt travel. If you still have not found the problem, then it is time to go over your conveyor from tail to head and ensure that it is level across the width of the conveyor at every seem in the sections. A twisting conveyor frame can cause tracking issues.

-

How to support a chain conveyor?

Fluent Conveyors ships all our roller chain conveyors with welded on rigging points. It is recommended that you use these for all lifting and rigging. The pit sections can be strapped around the rail. Fluent Conveyors designs all our conveyors with supports and support attachment locations. Please consult your install drawings to confirm that you are using the correct locations.

-

What to do with old conveyor belts?

Fluent Conveyors recommends that you recycle all old conveyor belts.

-

How long will it take to deliver a replacement hinged steel conveyor belt?

Fluent Conveyors hinged steel conveyor belts normally take 4-6 weeks plus shipping for belts that follow industry standard specifications. Please contact our sales team and we can get started with you immediately.

Factors that would speed this up or slow it down include current production schedule, thickness of belting, additional options and complexity of the specific belt.