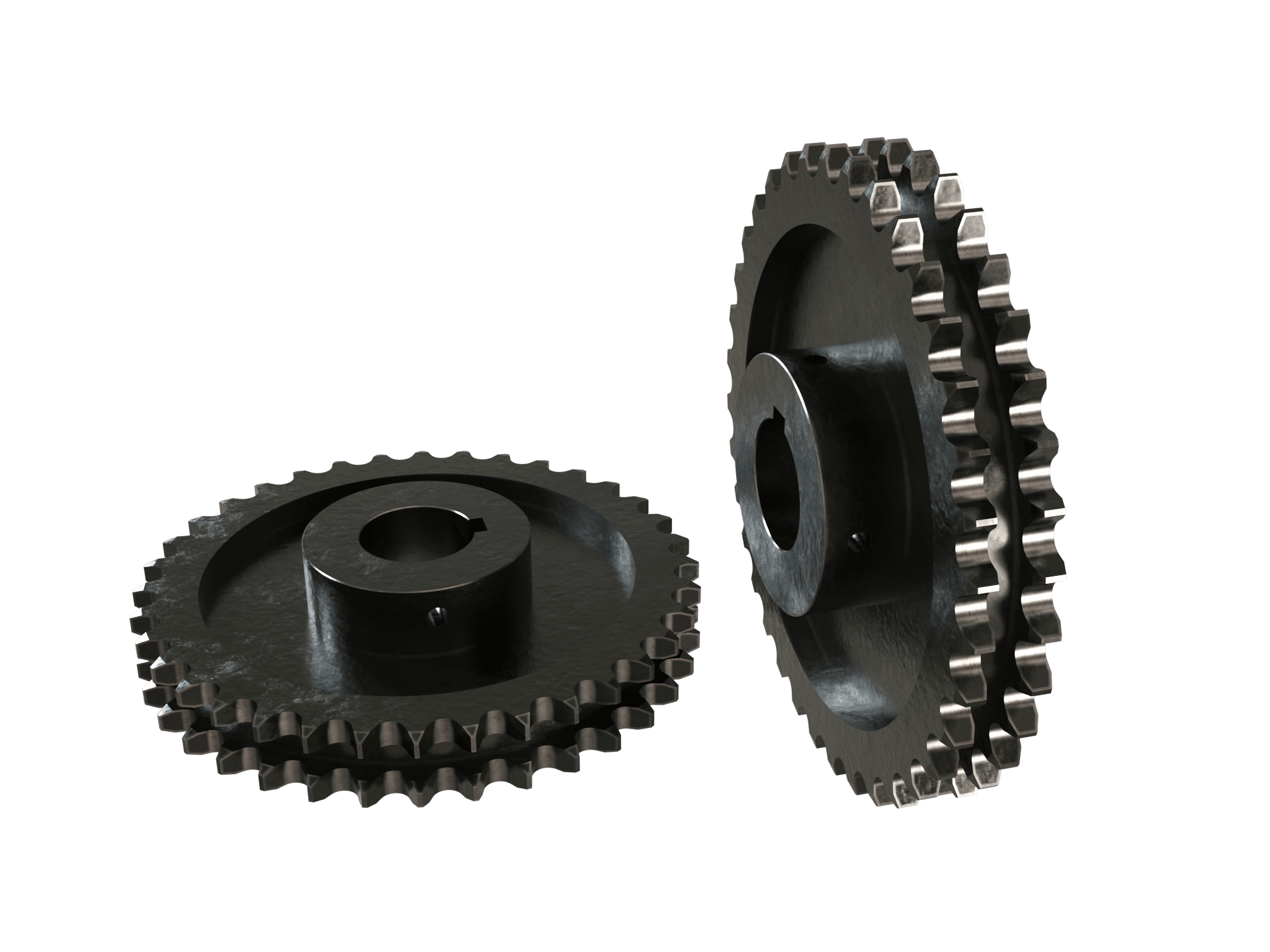

Replacement Conveyor Sprockets

Balancing Chain Performance & Simplifying Belt Tracking

Replacement Conveyor Sprocket Overview

Custom Head Sprockets

Custom Sprockets

Bronzed Bushed Tail

Yes

- 6 Tooth

- 7 Tooth

- 8 Tooth

- 9 Tooth

- Custom options upon request.

- Optional

- A

- B

- C

- D

- E

- F

- G

- H

- I

- J

- K

- L

- M

- N

- O

- P

- Optional

- 15/16”

- 1-3/16

- 1-7/16”

- 1-11/16”

- 1-15/16”

- 2-3/16”

- 2-7/16”

- 2-11/16”

- 2-15/16”

- 3-3/16”

- 3-7/16

- 3-11/16

- 3-15/16”

- 4-7/16”

- 4-15/16”

- 5-7/16”

- 5-15/16"

- 6.5"

- 7"

- 7.5"

- 8"

- 8.5"

- 9"

- 9.5"

- 10"

As well as producing bespoke conveyor systems, we also supply custom replacement belts and parts to ensure no client sees their assembly line stay offline for an extended period of time. From replacement motors to sprockets, everything is covered if a client comes across a failing element of their conveyor system.

Sadly, it’s inevitable your clients will face some type of issue with their conveyor system at some point. Even with Fluent Conveyors’ best equipment in place, conveyors are going to suffer from wear and tear due to their demanding nature. However, being able to offer a solution at any time will be appreciated by your clients.

Are You Looking For A Easy & Seamless Way To Order New Conveyor Sprocket?

Our Process Is Typically Very Lean & Detailed! We Prefer Not To Waste Our Customers Time!

Please Contact Us If You Want Help On Your Conveyor Belt & You Are Comfortable With:

- Price Can Range For Each Sprocket From $1,000 - $2,500+

- Lead Time of 1–3 Weeks+ (Depending on idler requirements)

- You have visited our resource center and have all the required dimensions

- Have the ability to review & sign approval drawings

- 100% pre-payment before manufacturing. These are made to order per your specifications & can't be returned

-

How to attach a sprocket to a conveyor shaft?

There are many different sprocket/shaft interface options. If you have a sprocket from a Fluent conveyor then it should be a bored keyed connection. We have drawings and videos depicting the process for sprocket replacement. Call us and we can supply you out with the replacement sprockets.

If you do not have a conveyor made by Fluent Conveyors the process may be very different. Call our main line and we can help to provide you with information or conveyor service in your area.

-

How to change conveyor speed with a sprocket change?

It is possible to change the speed of a conveyor by changing the sprocket size.

If the sprocket is part of a sprocket and chain reduction, we recommend only changing the size of the larger sprocket. Using a sprocket with more teeth will slow the conveyor down and add more torque at the belt (easier for the motor to pull). Using a sprocket with fewer teeth will speed the conveyor up and reduce the torque at the belt (harder for the motor to pull) If you are speeding your conveyor up it is possible to push outside of the power of your motor and cause the overload to trip or the belt to fail to turn. Call our main line if you need further assistance.

If the sprocket is a drive sprocket on a roller chain conveyor, then make sure you are changing both the left and the right-hand side to the same size to ensure the belt pulls correctly. Sizing up will cause a higher belt speed, but increase the load at the motor. Sizing down will cause a lower belt speed but decrease the load at the motor allowing for larger loads on the belt. Caution, sometimes the sprockets are already the smallest size recommended for that >

-

How to repair a conveyor sprocket?

Repairing a conveyor sprocket is generally not recommended. Conveyor sprockets are relatively inexpensive when compared to the cost of the conveyor. Please contact the Fluent Conveyors sales team and we can help you replace your broken sprocket.

-

How long will it take to deliver a replacement sprocket?

Standard replacement sprockets typically take an average of 2-3 weeks from the time of purchase order and signed approval drawings.

-

How to attach a sprocket to a conveyor shaft?

There are many different sprocket/shaft interface options. If you have a sprocket from a Fluent conveyor then it should be a bored keyed connection. We have drawings and videos depicting the process for sprocket replacement. Call us and we can supply you out with the replacement sprockets.

If you do not have a conveyor made by Fluent Conveyors the process may be very different. Call our main line and we can help to provide you with information or conveyor service in your area.

-

How to change conveyor speed with a sprocket change?

It is possible to change the speed of a conveyor by changing the sprocket size.

If the sprocket is part of a sprocket and chain reduction, we recommend only changing the size of the larger sprocket. Using a sprocket with more teeth will slow the conveyor down and add more torque at the belt (easier for the motor to pull). Using a sprocket with fewer teeth will speed the conveyor up and reduce the torque at the belt (harder for the motor to pull) If you are speeding your conveyor up it is possible to push outside of the power of your motor and cause the overload to trip or the belt to fail to turn. Call our main line if you need further assistance.

If the sprocket is a drive sprocket on a roller chain conveyor, then make sure you are changing both the left and the right-hand side to the same size to ensure the belt pulls correctly. Sizing up will cause a higher belt speed, but increase the load at the motor. Sizing down will cause a lower belt speed but decrease the load at the motor allowing for larger loads on the belt. Caution, sometimes the sprockets are already the smallest size recommended for that >

-

How to repair a conveyor sprocket?

Repairing a conveyor sprocket is generally not recommended. Conveyor sprockets are relatively inexpensive when compared to the cost of the conveyor. Please contact the Fluent Conveyors sales team and we can help you replace your broken sprocket.

-

How long will it take to deliver a replacement sprocket?

Standard replacement sprockets typically take an average of 2-3 weeks from the time of purchase order and signed approval drawings.