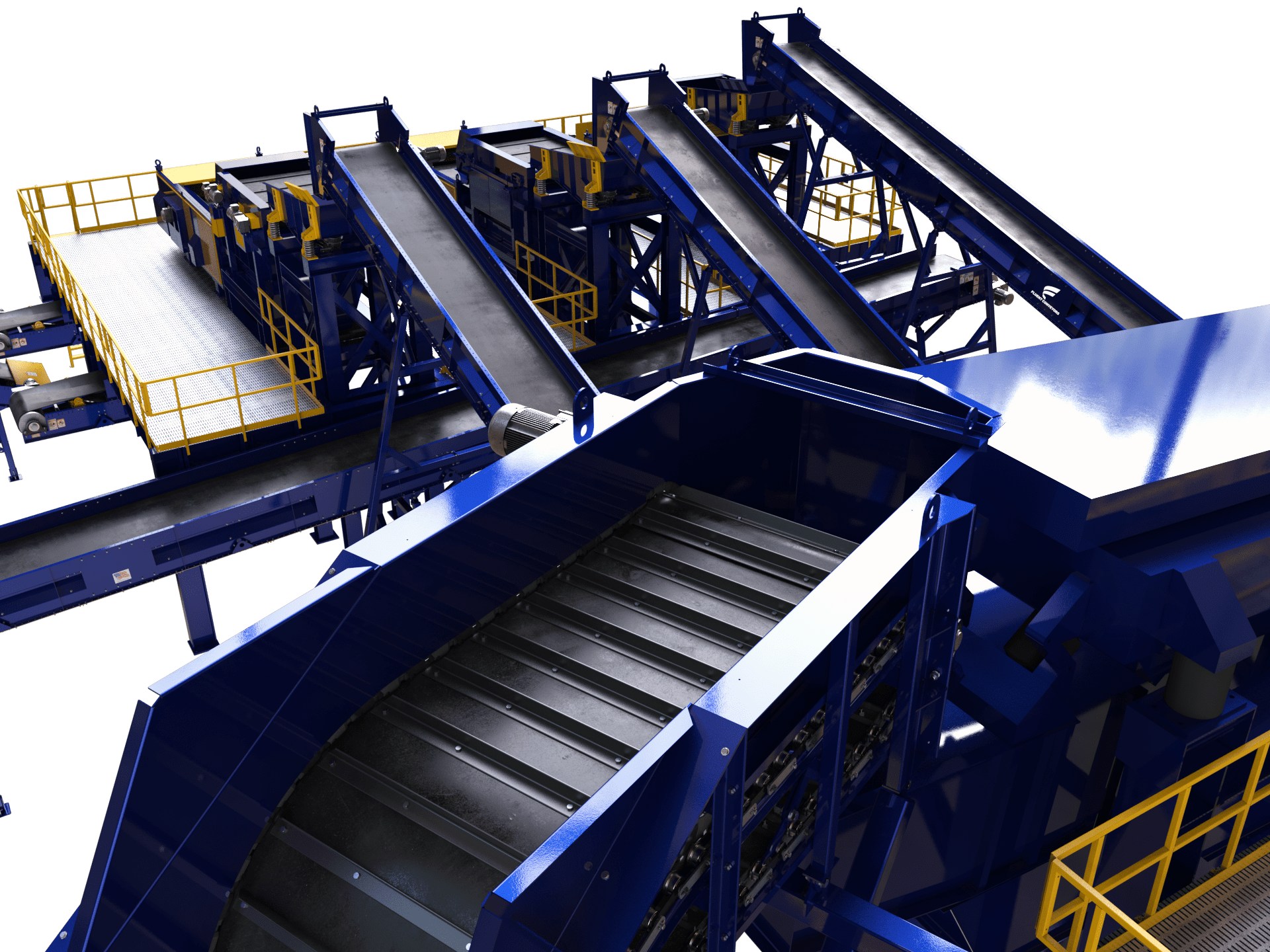

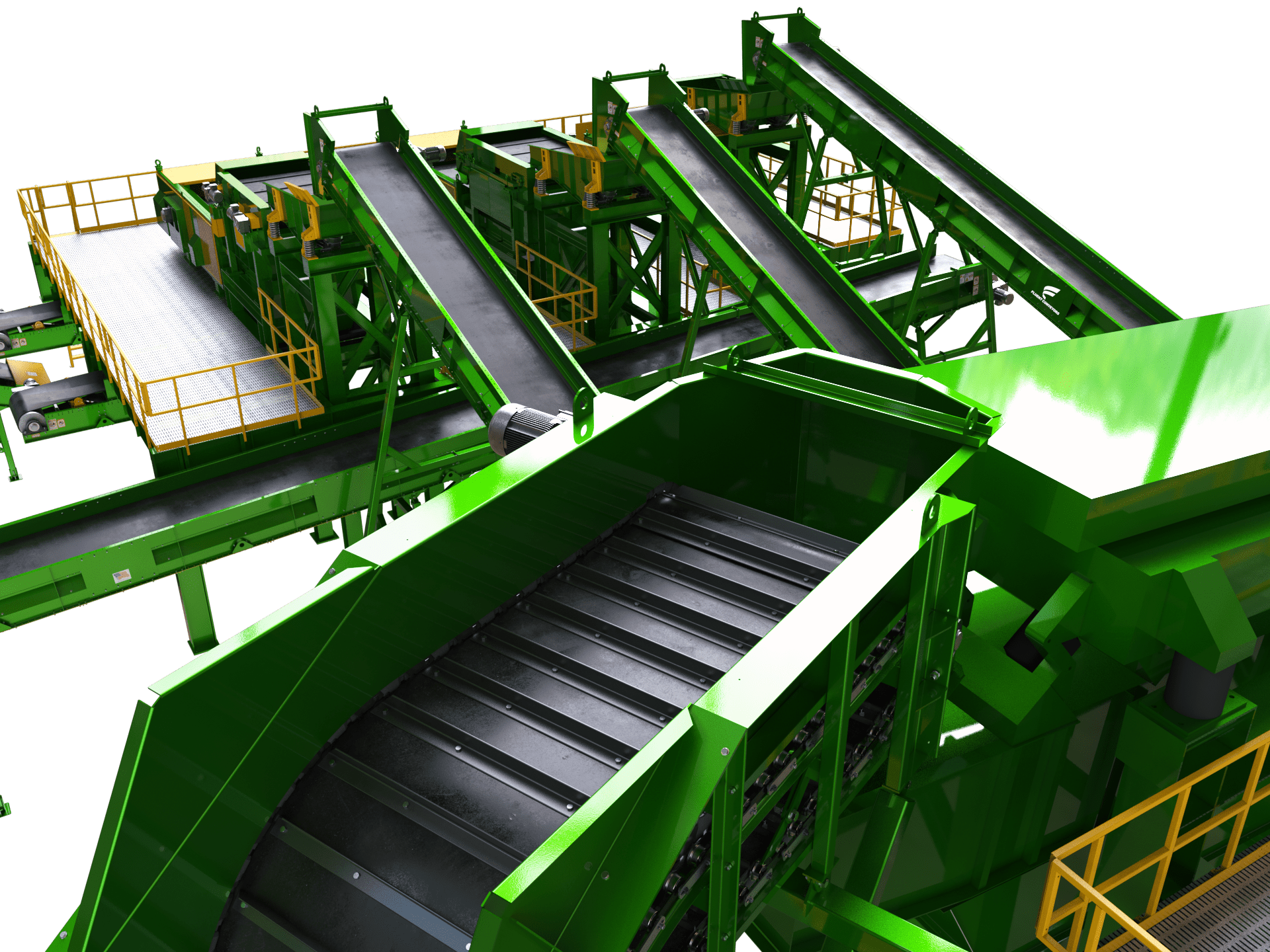

Custom Recycling Sort Systems

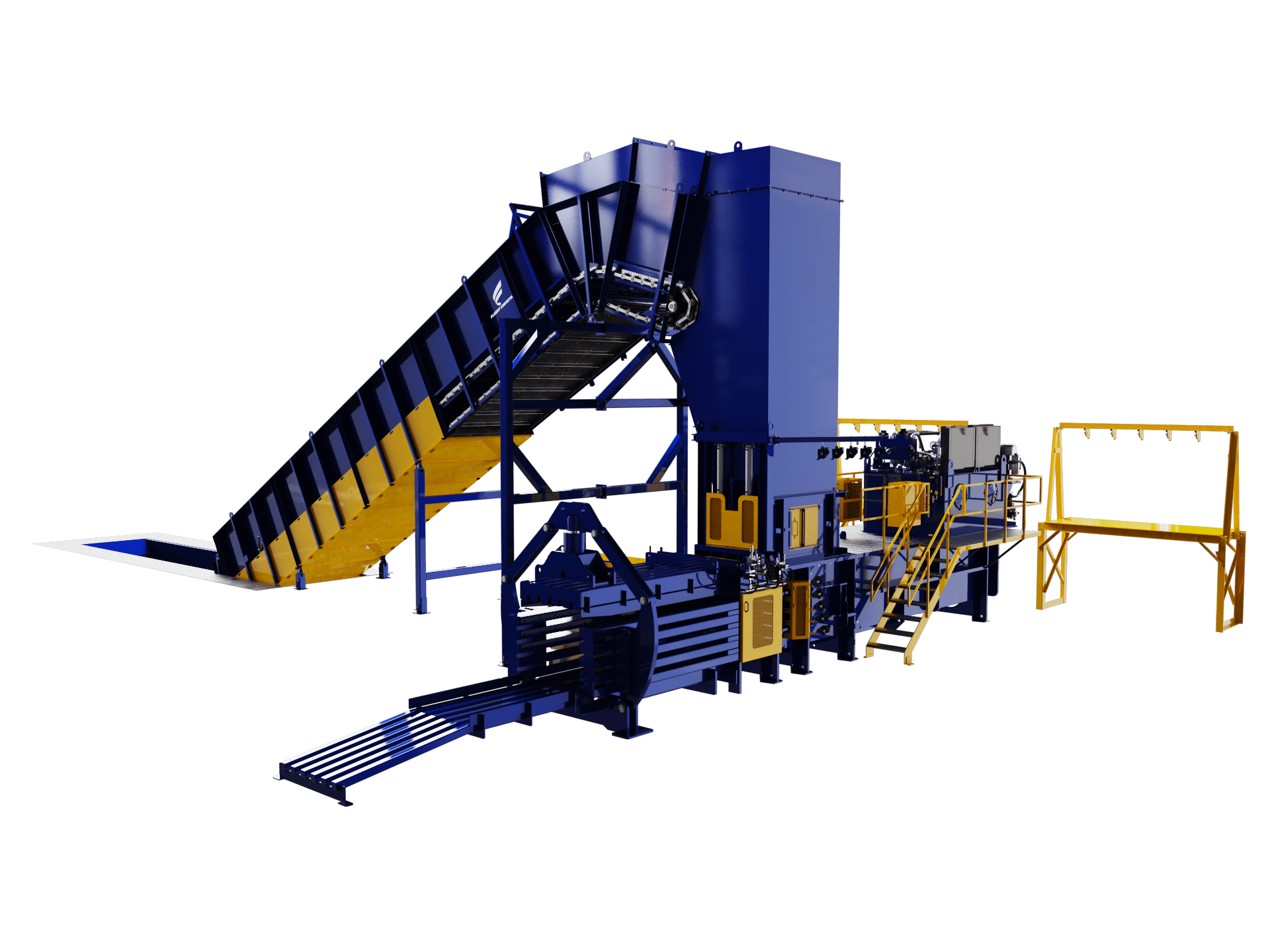

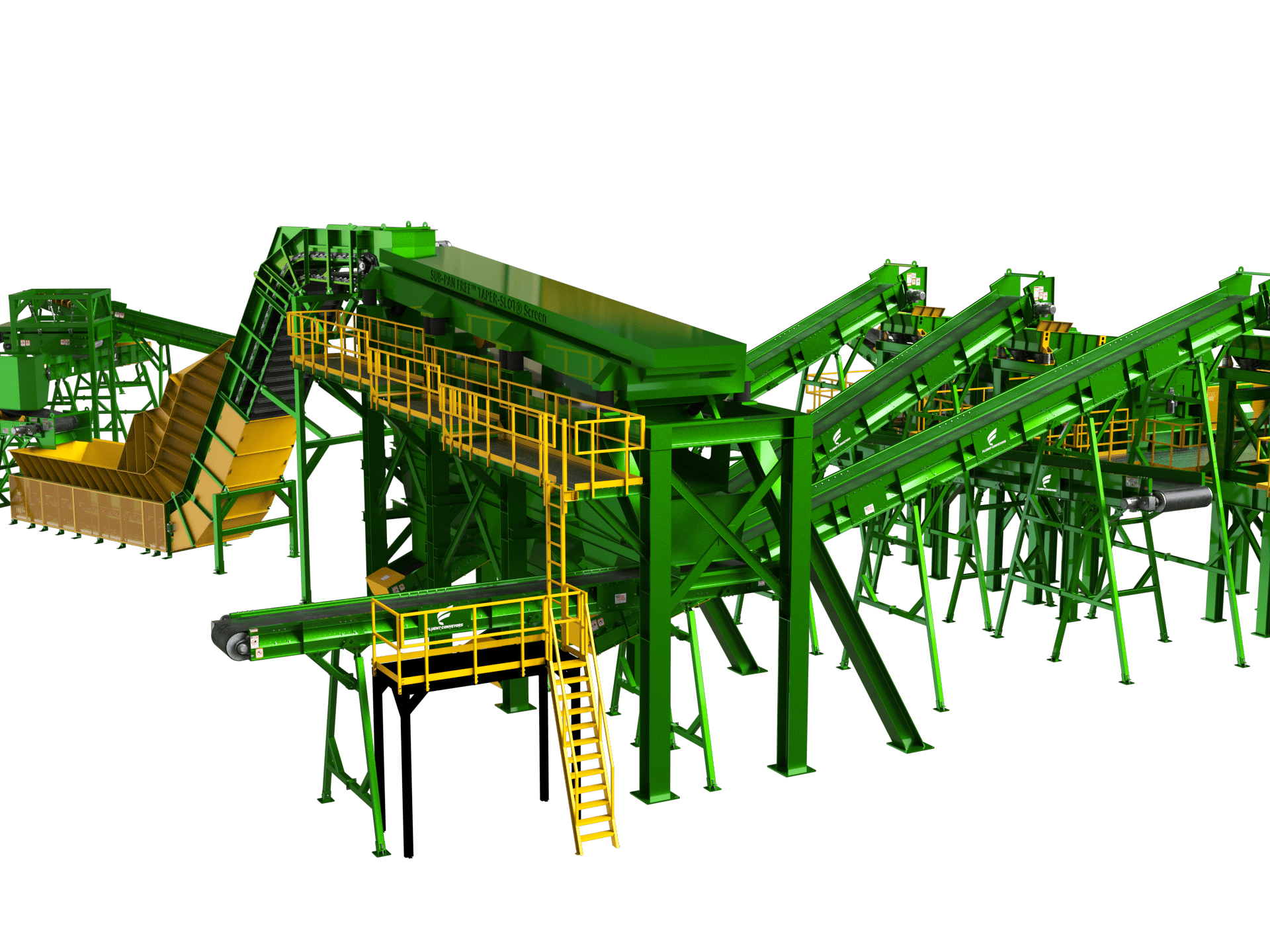

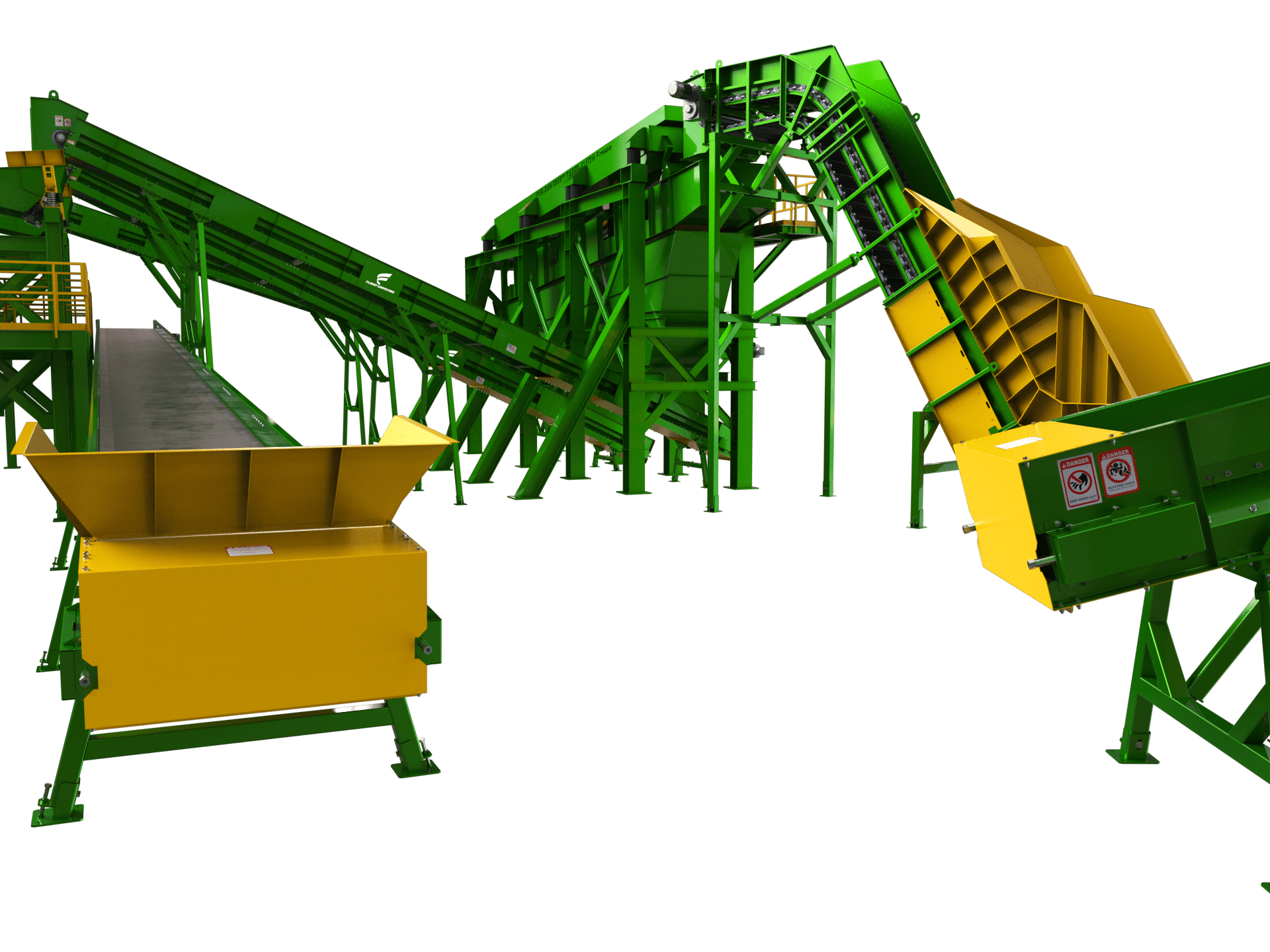

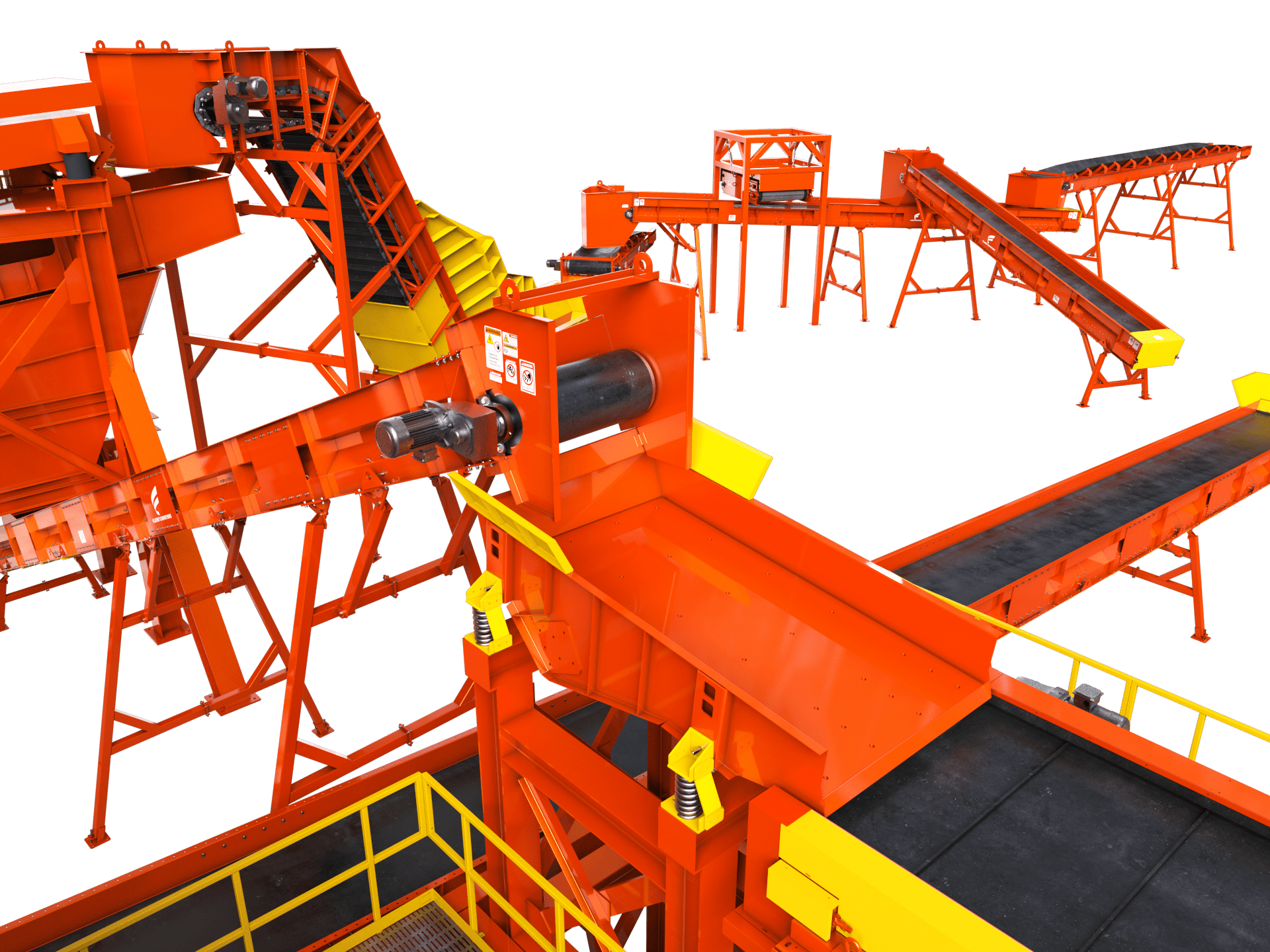

Fluent Conveyors Custom Recycling Systems Are Custom Designed To Fit Existing Buildings. Ideal For Customers Sorting Single Stream, MSW, Fibers, Plastics, Scrap & More!

Custom Recycling Sort System Series Overview

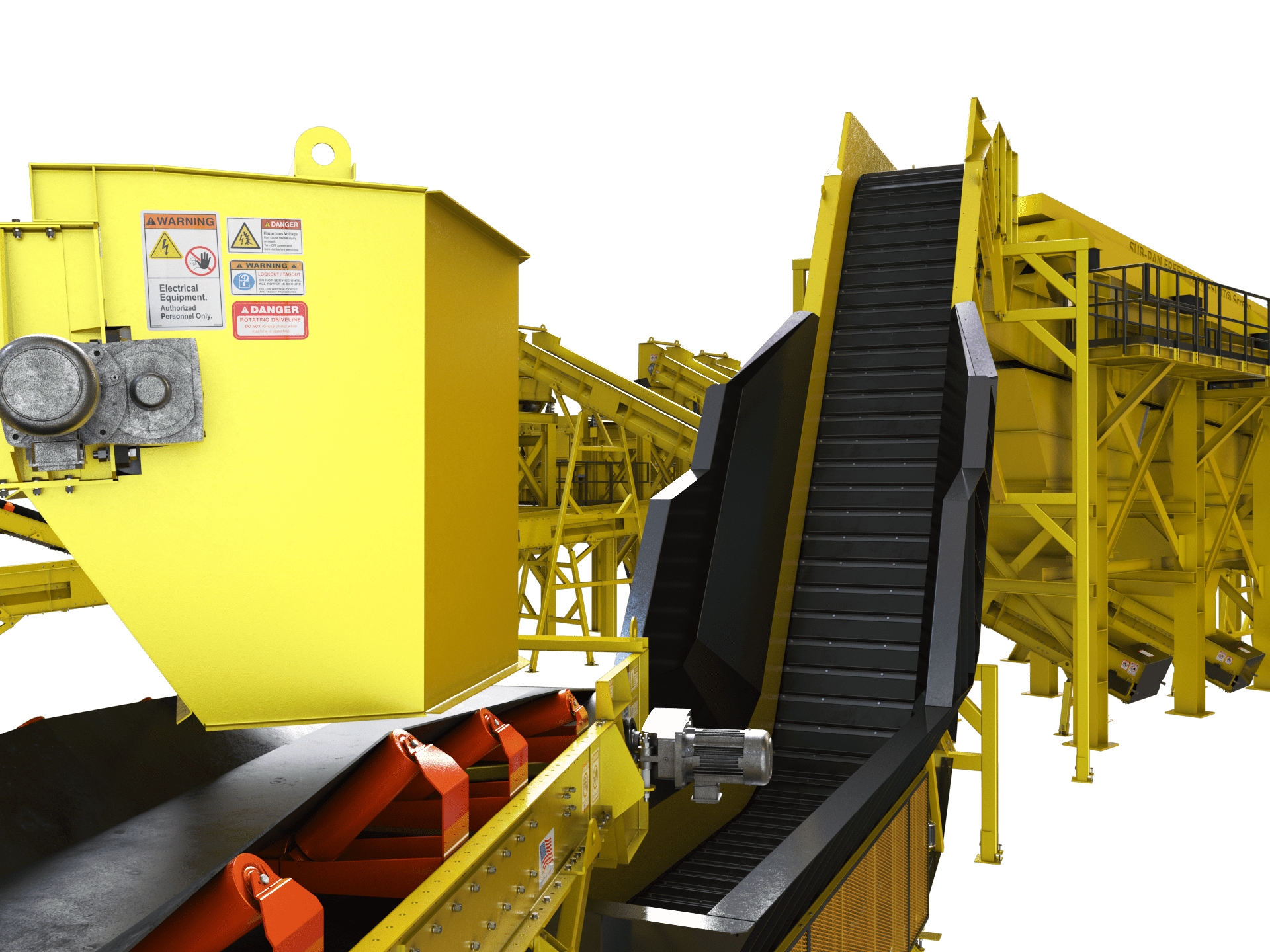

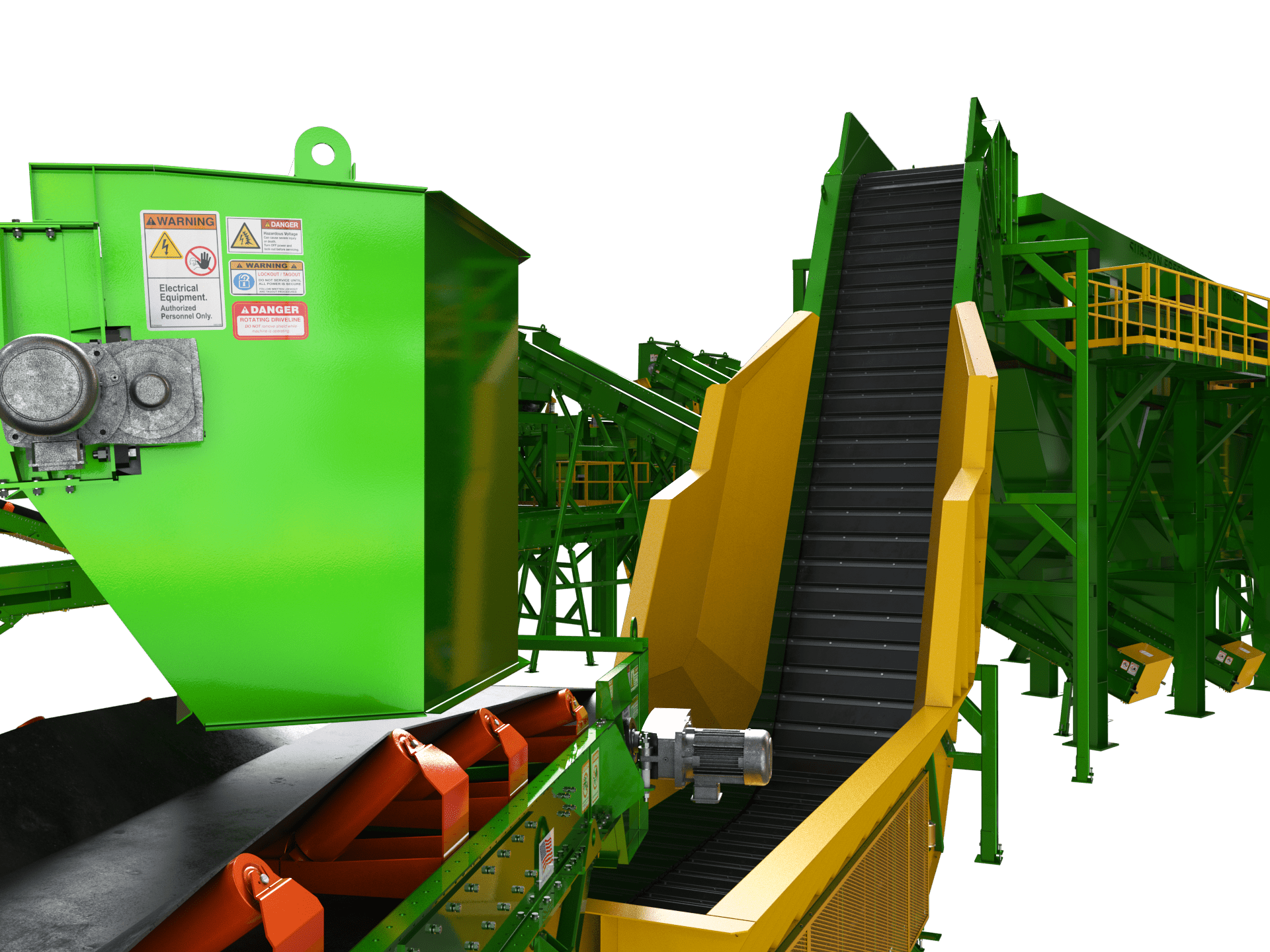

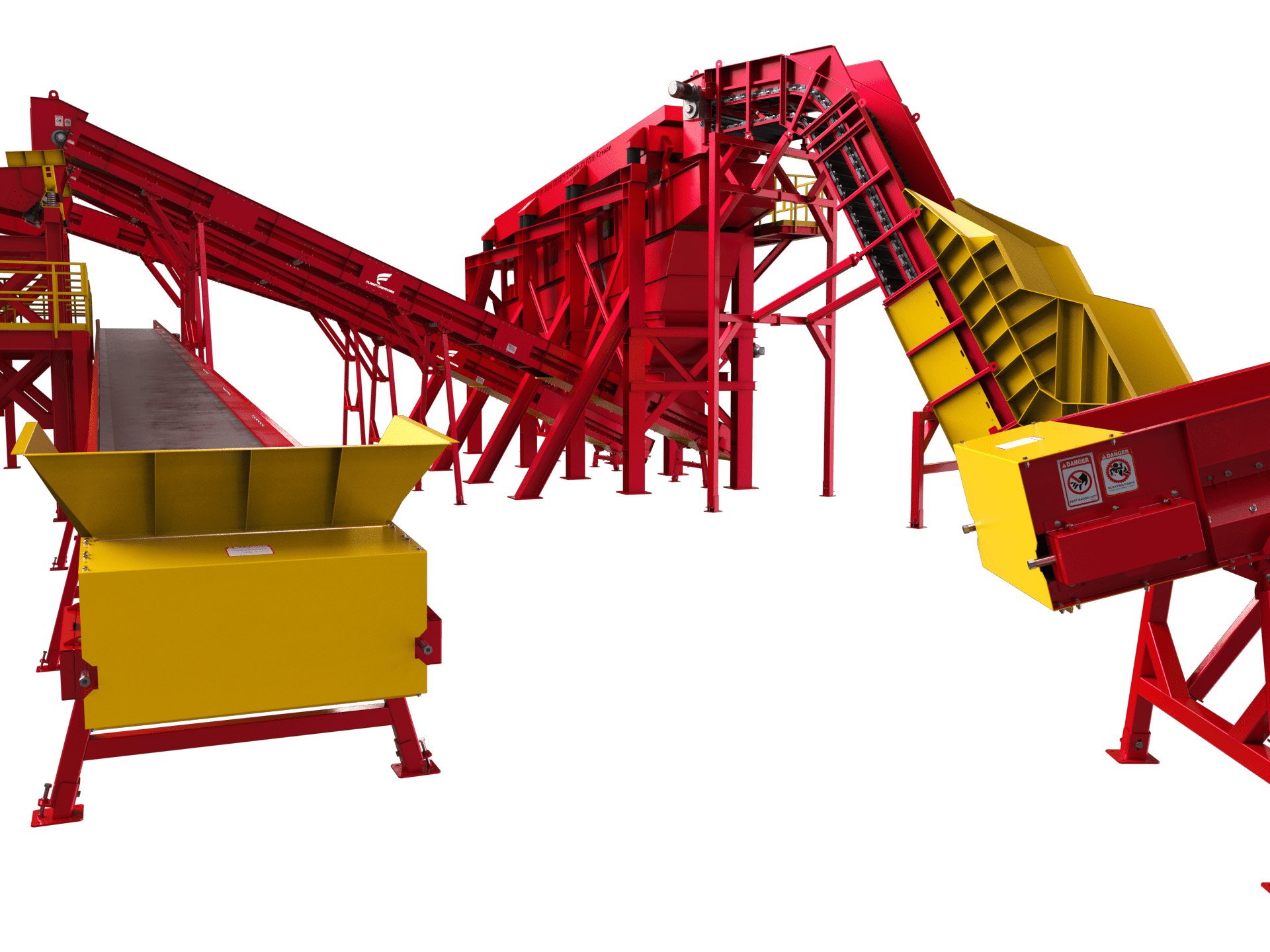

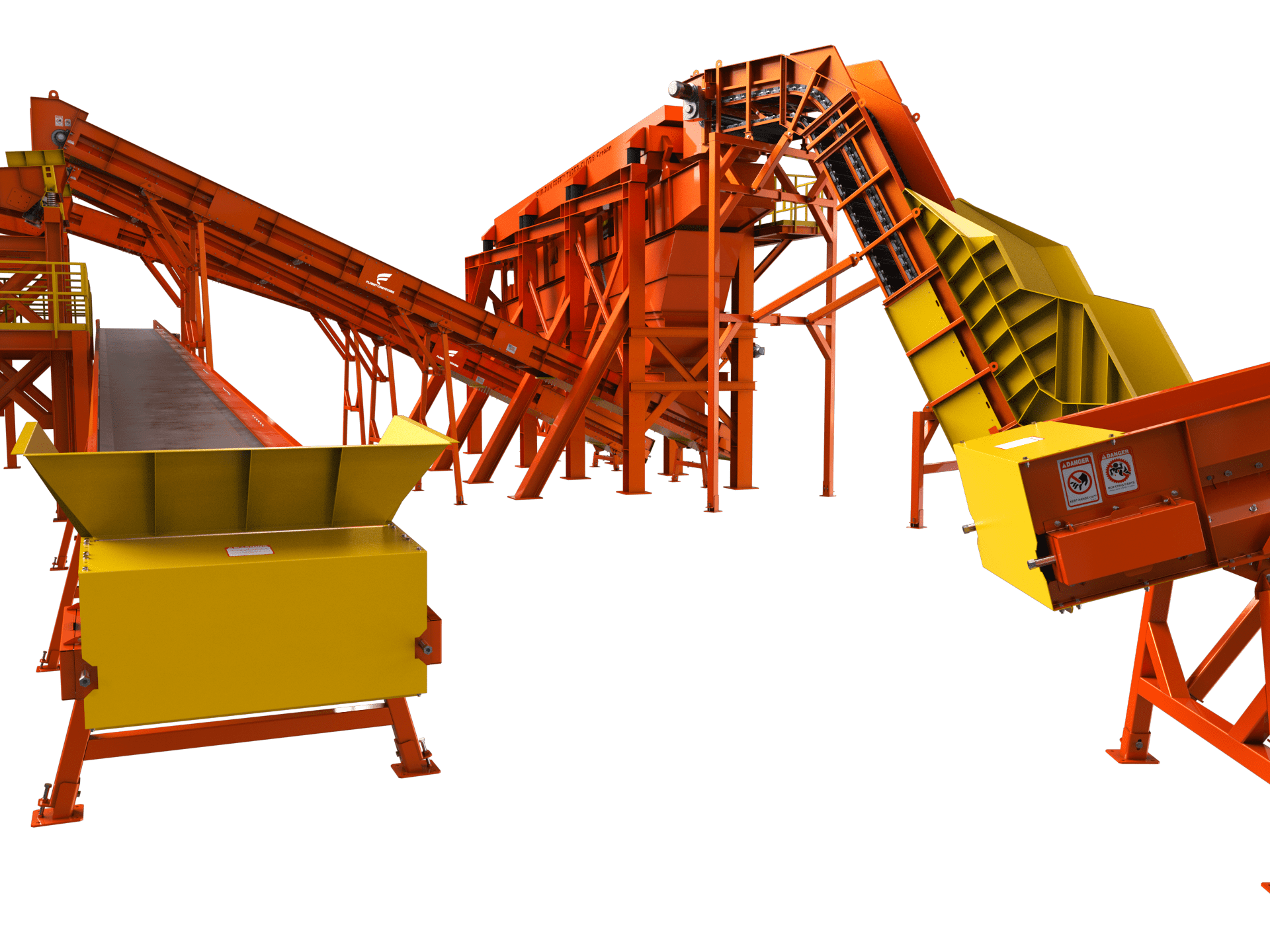

Fluent RC Series of Conveyors are engineered with industry leading 3D CAD software and manufactured with precision (tolerances and standards). This series comes in standard and custom widths and lengths. Standard roller chain conveyor widths include 36″, 48″ 60”, 72″, 84”, 96”, 108” & 120”. Lower Horizontal lengths come in standard sizes of 10 feet, 15 feet 20 feet, 25 feet and 30 feet as well as any custom lower horizontal length to best match project specifications. The incline angles range from 25 degrees to 35 degrees depending on the application, material, baler requirements and building specifications. The standard chain sizes include 3 inch rollers with a 6 or 9 inch pitch, 4 & 5 inch roller with a 9 inch pitch. The frame is made of 3/16″ steel rectangular tubing, 1/4″ steel pan side walls, 1/4” steel rectangular tubing for supports & 25# – 30# rail track for chain support. The RC Series is MIG welded with certified welders and validated with a seamless QA process for overall structural integrity.

The Fluent RC Conveyors are sand blasted prior to paint, connected with grade 8 hardware (resist corrosion and increase strength), assembled and test run for over 10 hours prior to shipping. This series features industry leading components which include: rubber combo belts, apron pan belts, double beaded apron pan, z pan belts, hinged steel belts, motors, flame cut & hardened sprockets, electric oilers, coped angled cleats (2″, 3″, 4″ & 5″), side guards, bottom guards, e-stops, direct shaft mounted drives, cold rolled shafts and more.

This heavy duty series of conveyor is engineered and manufactured for the most extreme applications: wet, dry, high temps, e-waste, OCC, ONP, MSW, single stream, C&D, mining, biofuel, scrap, tire, stover, bagasse and more.

* We offer custom roller chain conveyors to meet the specific requirements for a wide variety of specialized applications (metering conveyors, high impact loading conveyors, reversing conveyors, etc.).

**This series of conveyors is often found feeding shredders, granulators, pulpers, balers, conveyors and sort stations for industry leading manufactures like Vecoplan, SSI, Granu-Tech, Ameri-Shred, Hustler Conveyors, CP Manufacturing, BHS, Harris Equipment, International Baler Corporation, American Baler, Excel, Marathon, Balemaster, G-Baler, Sierra, IPS and more.

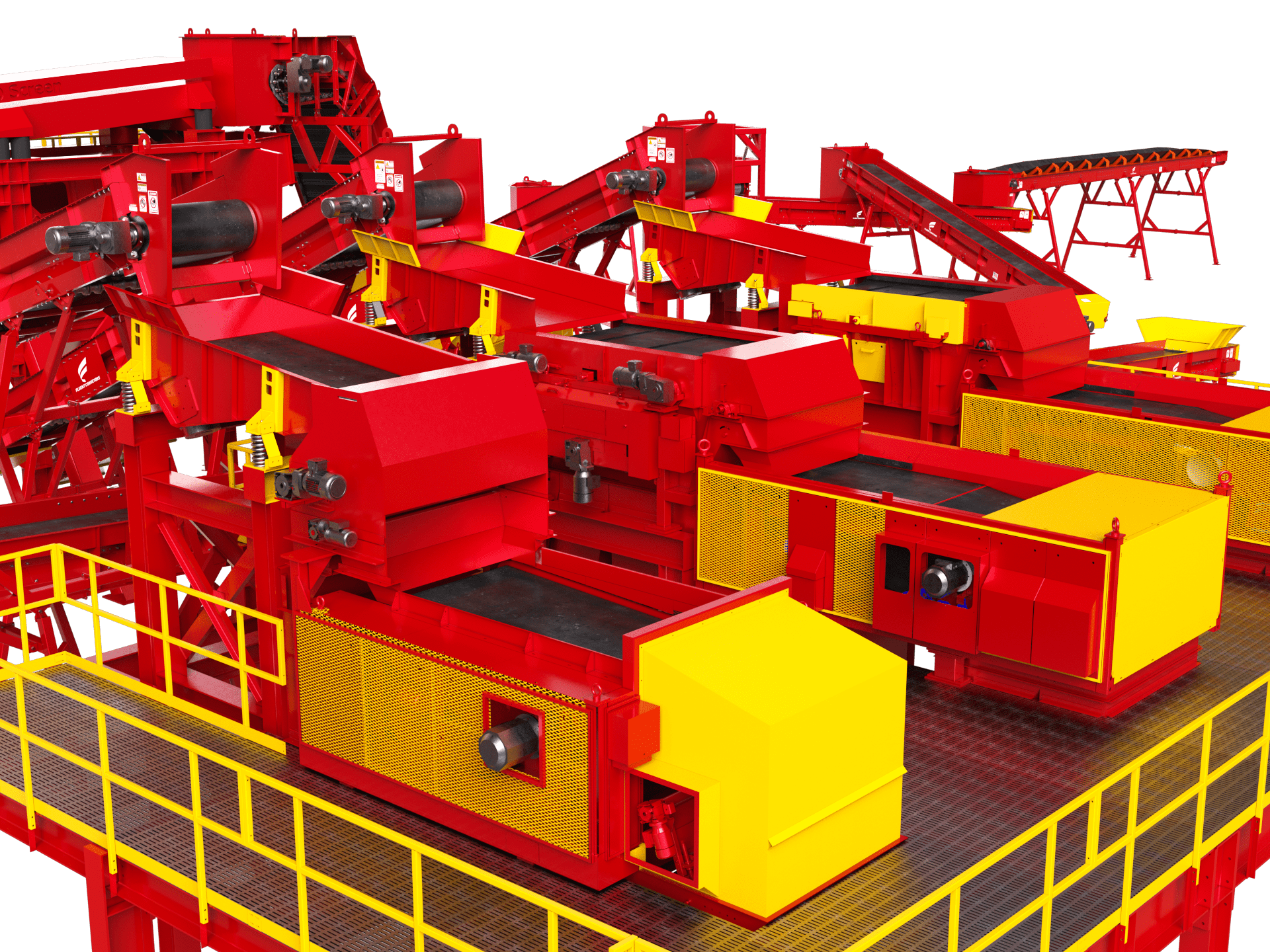

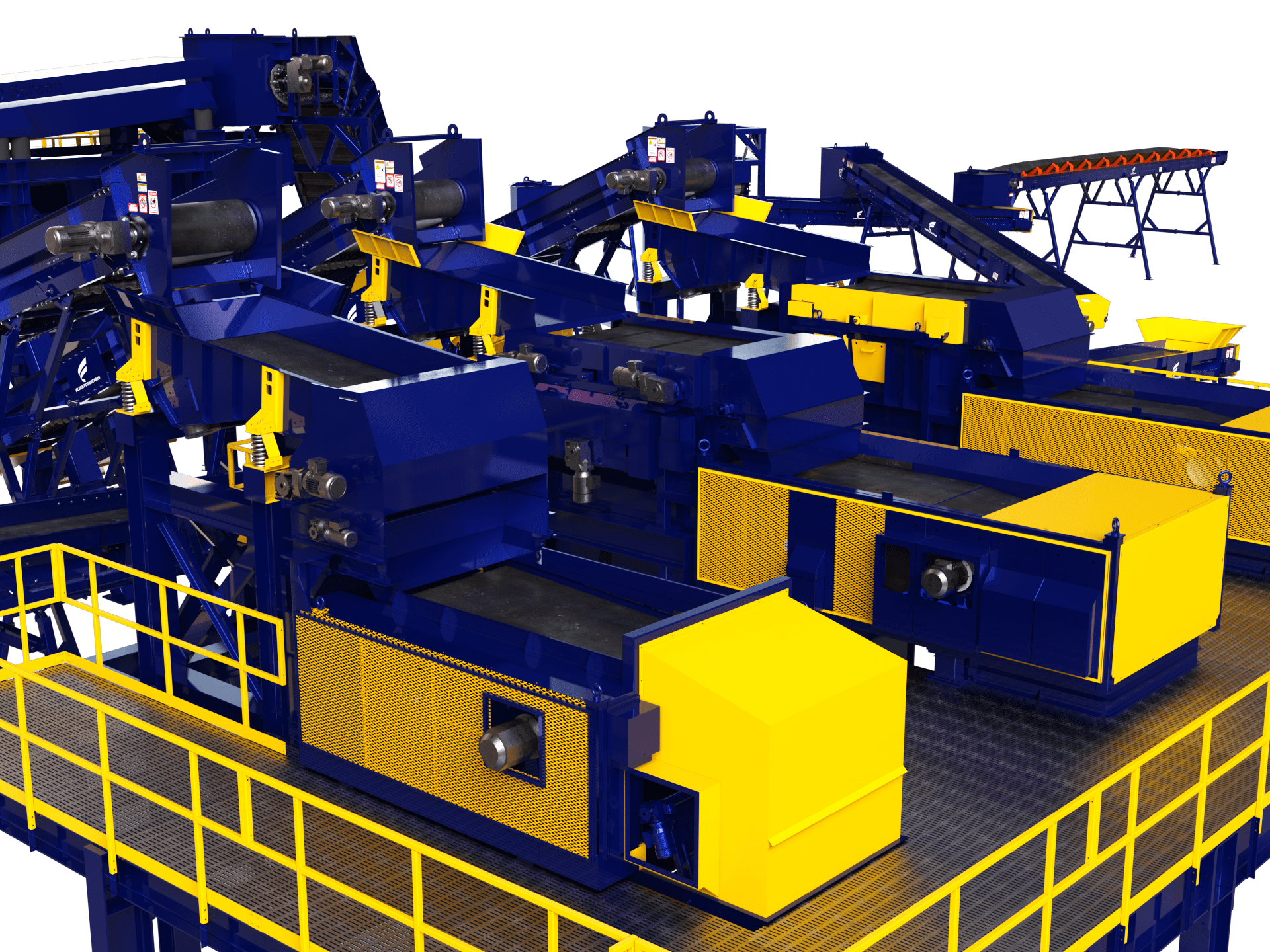

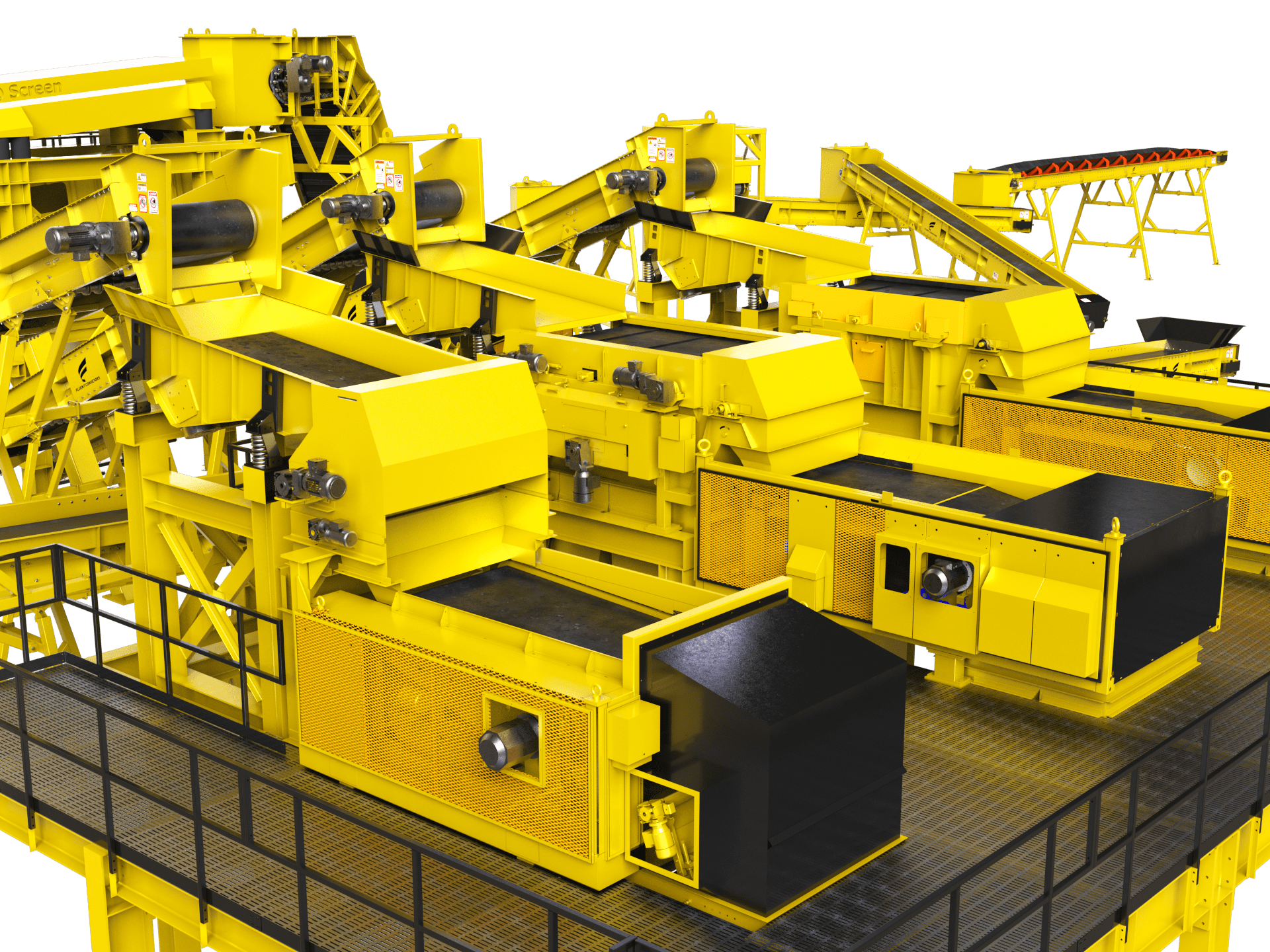

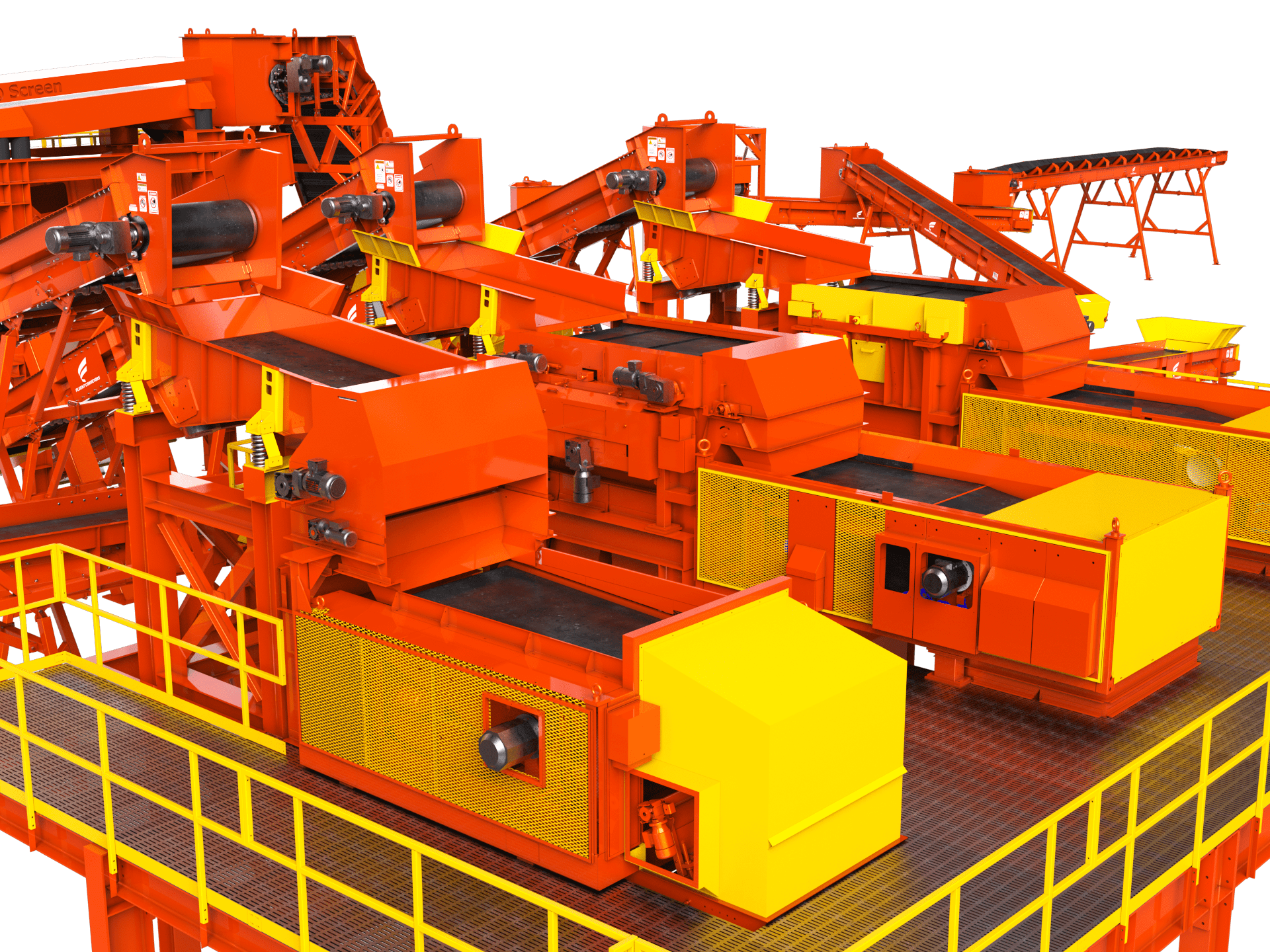

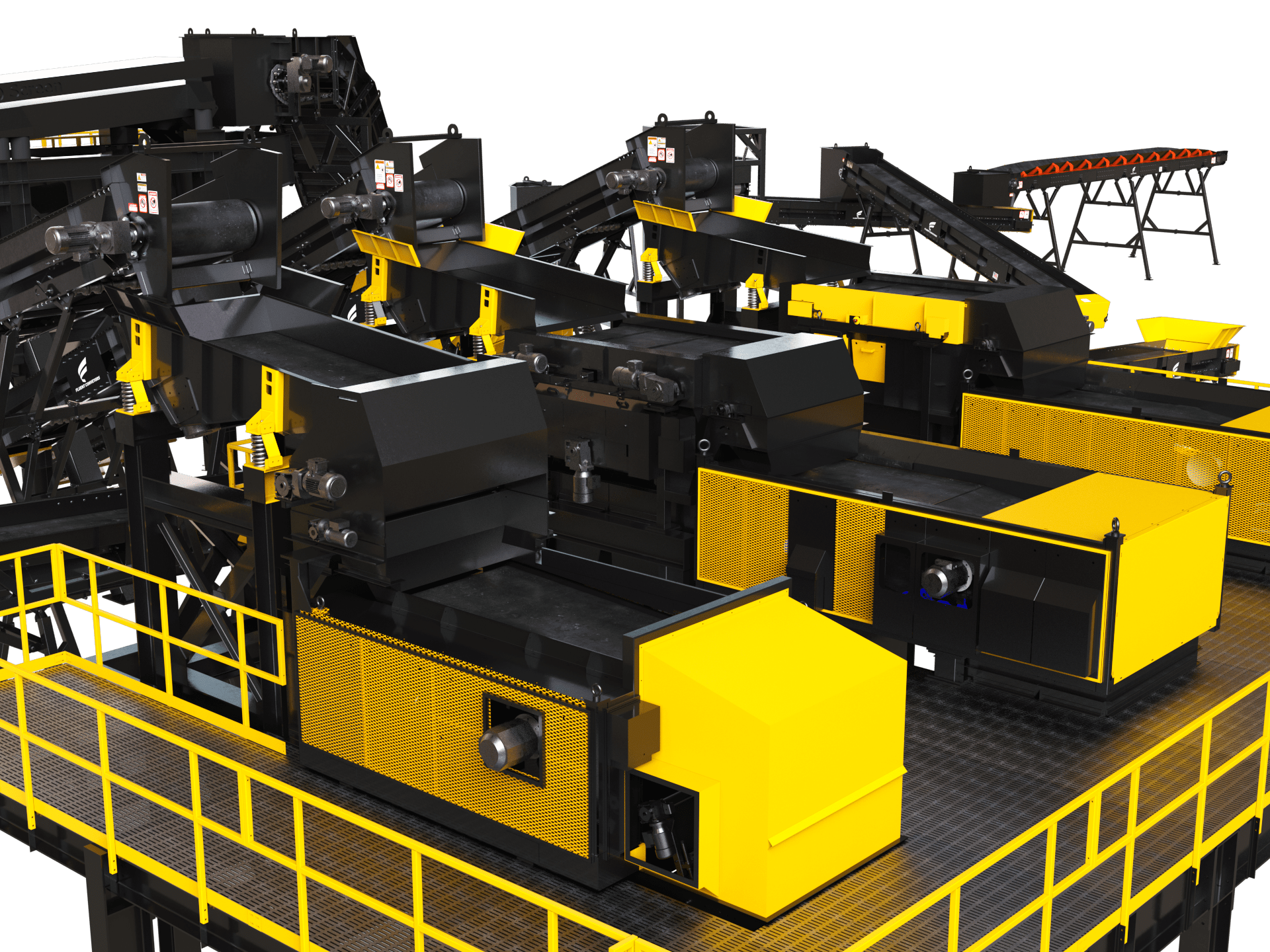

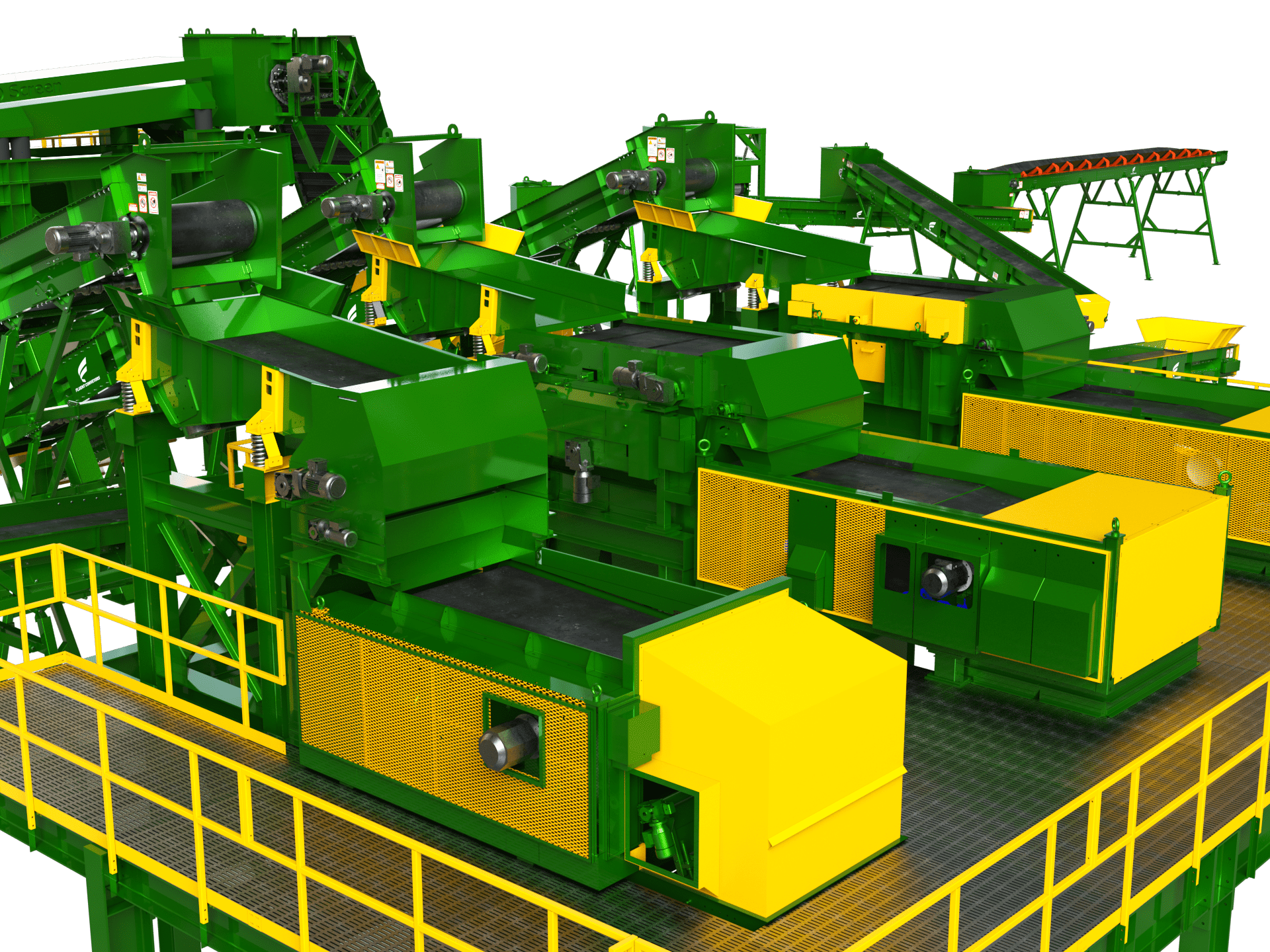

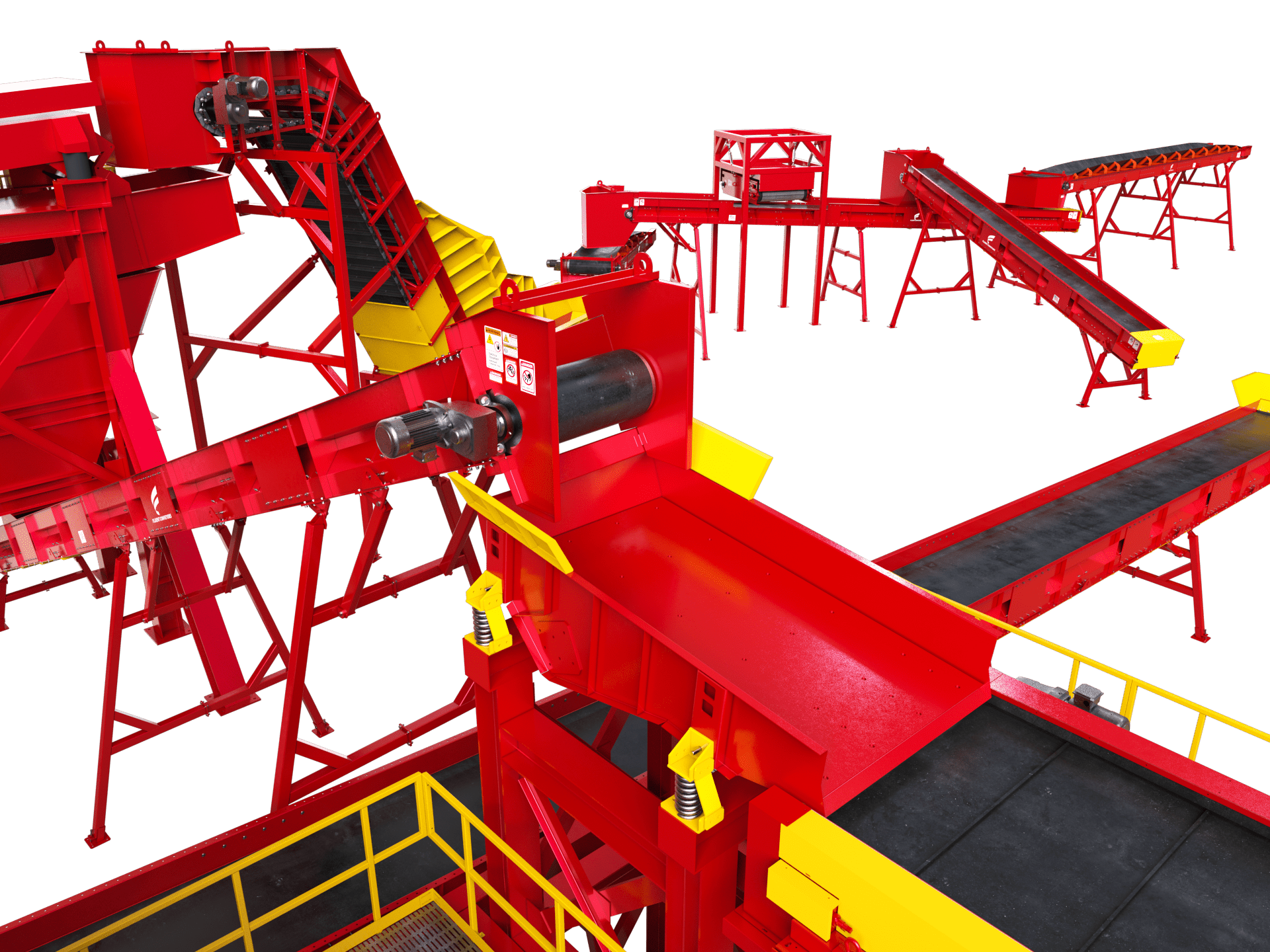

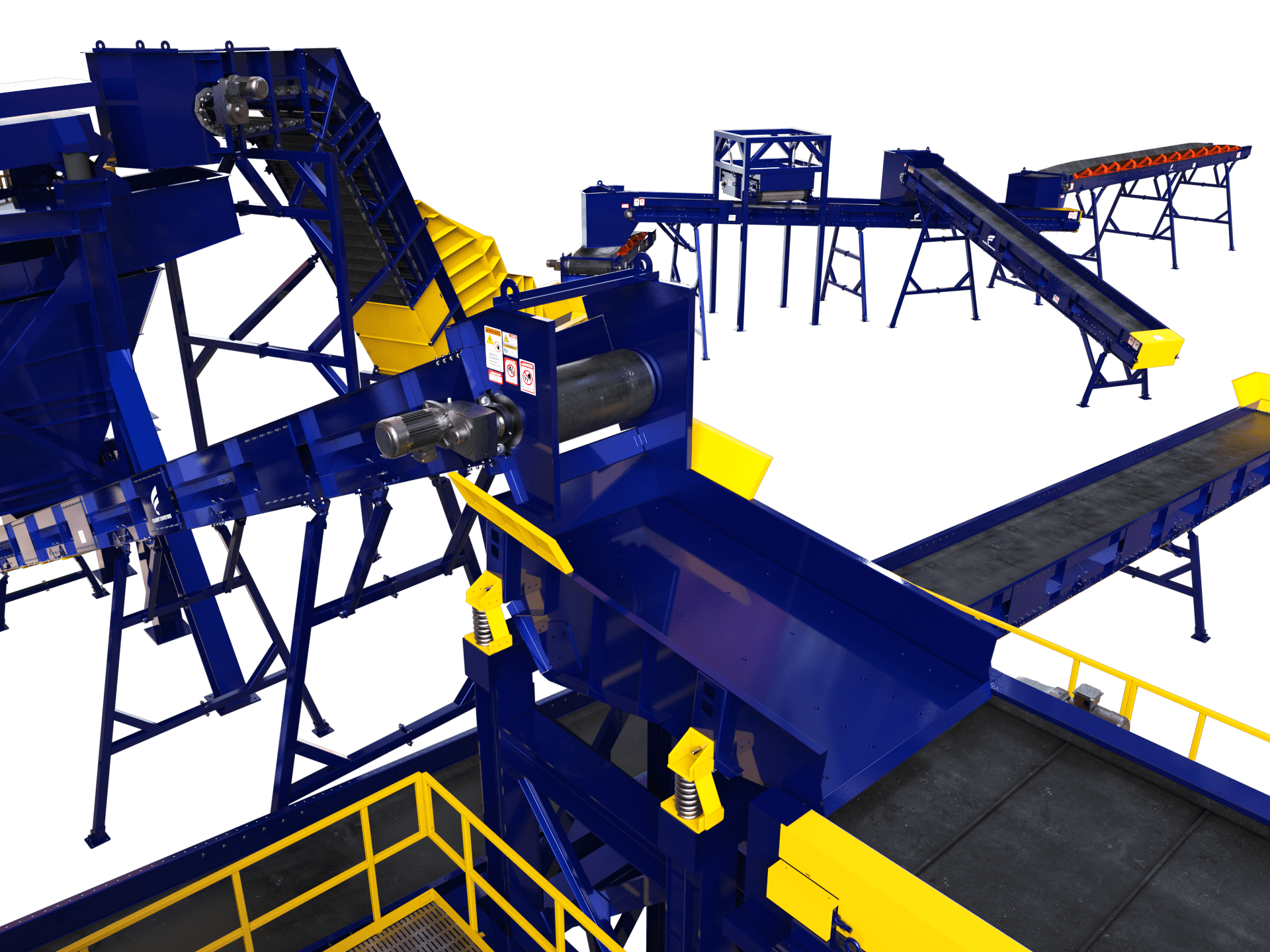

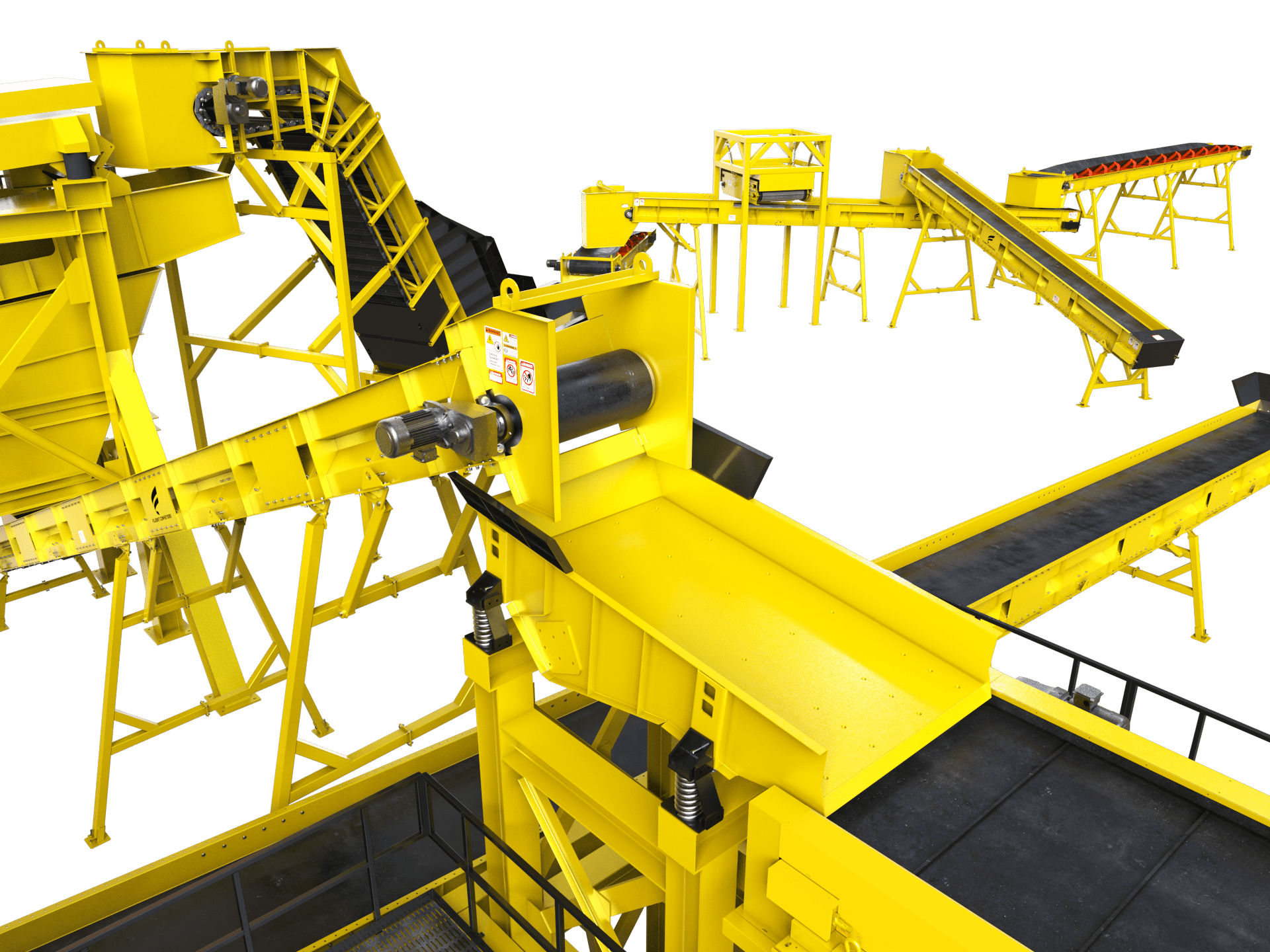

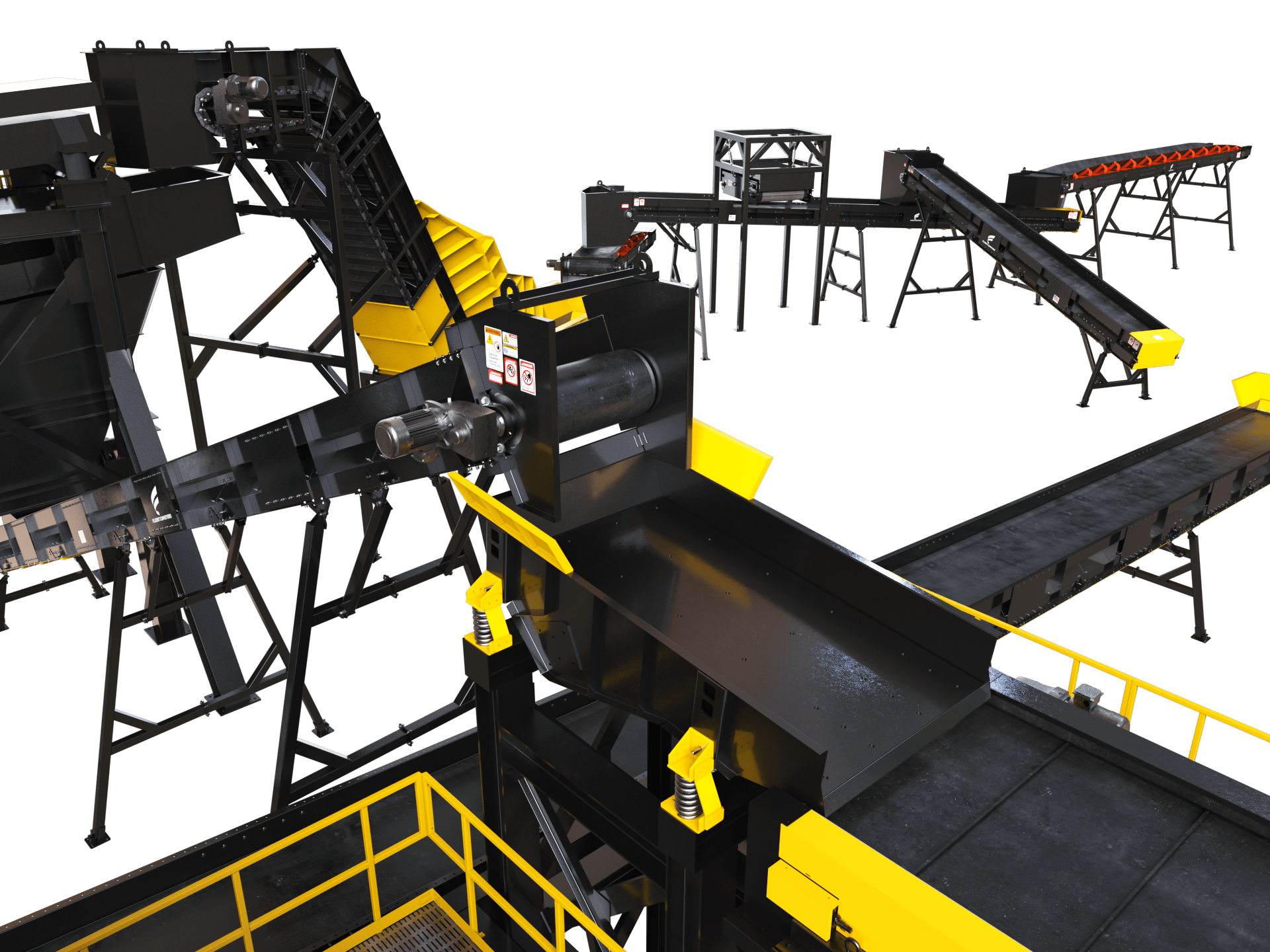

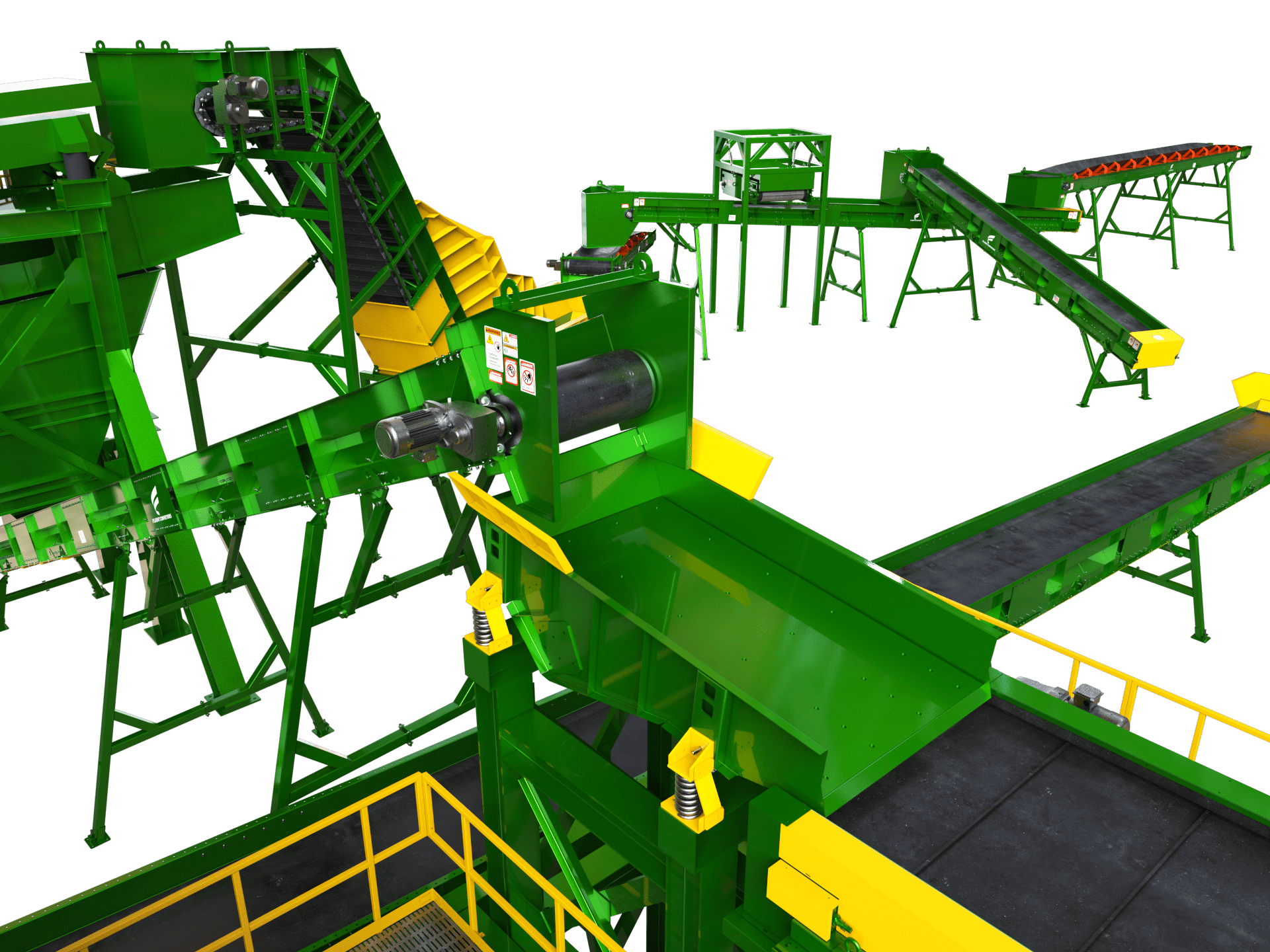

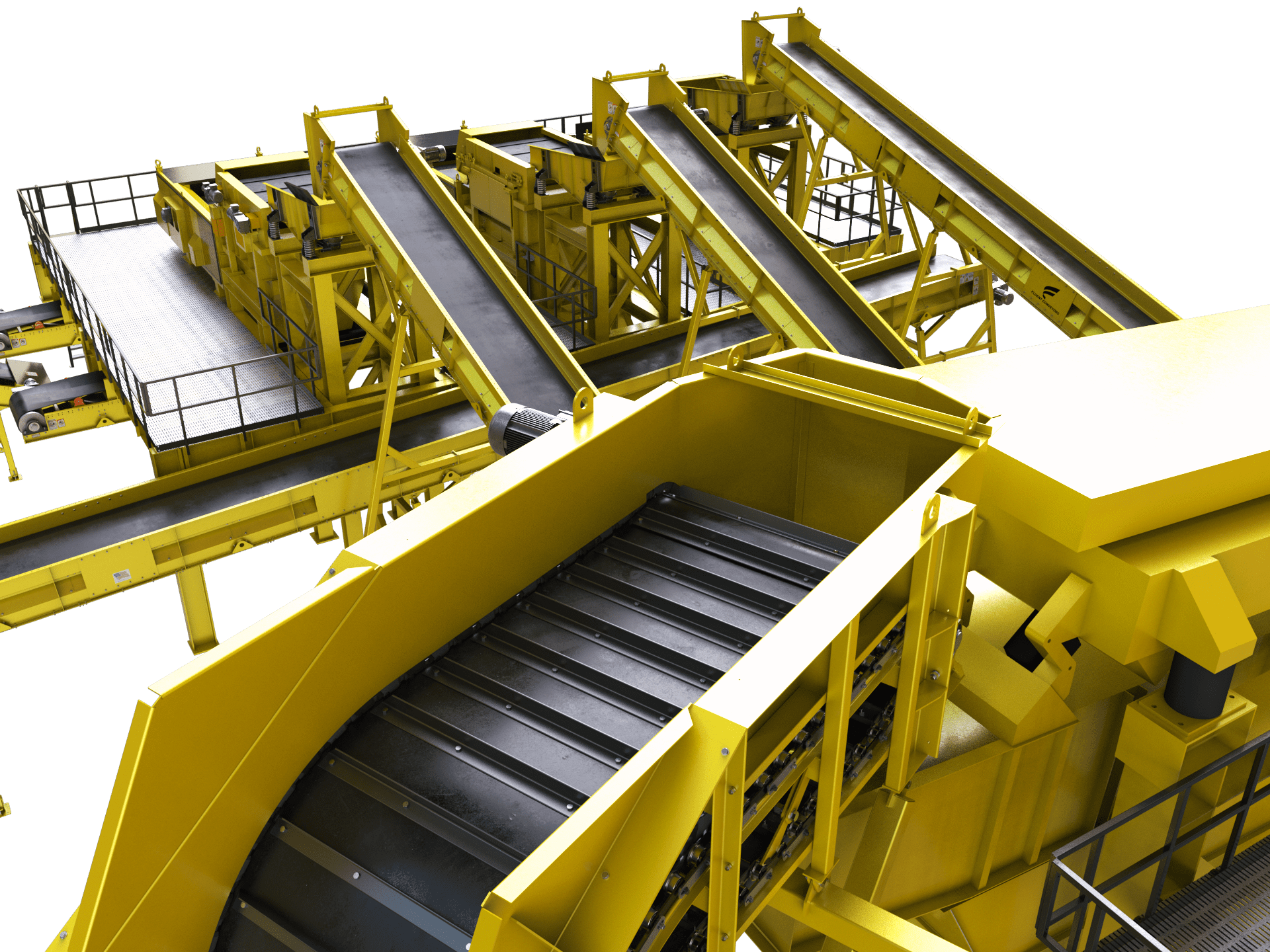

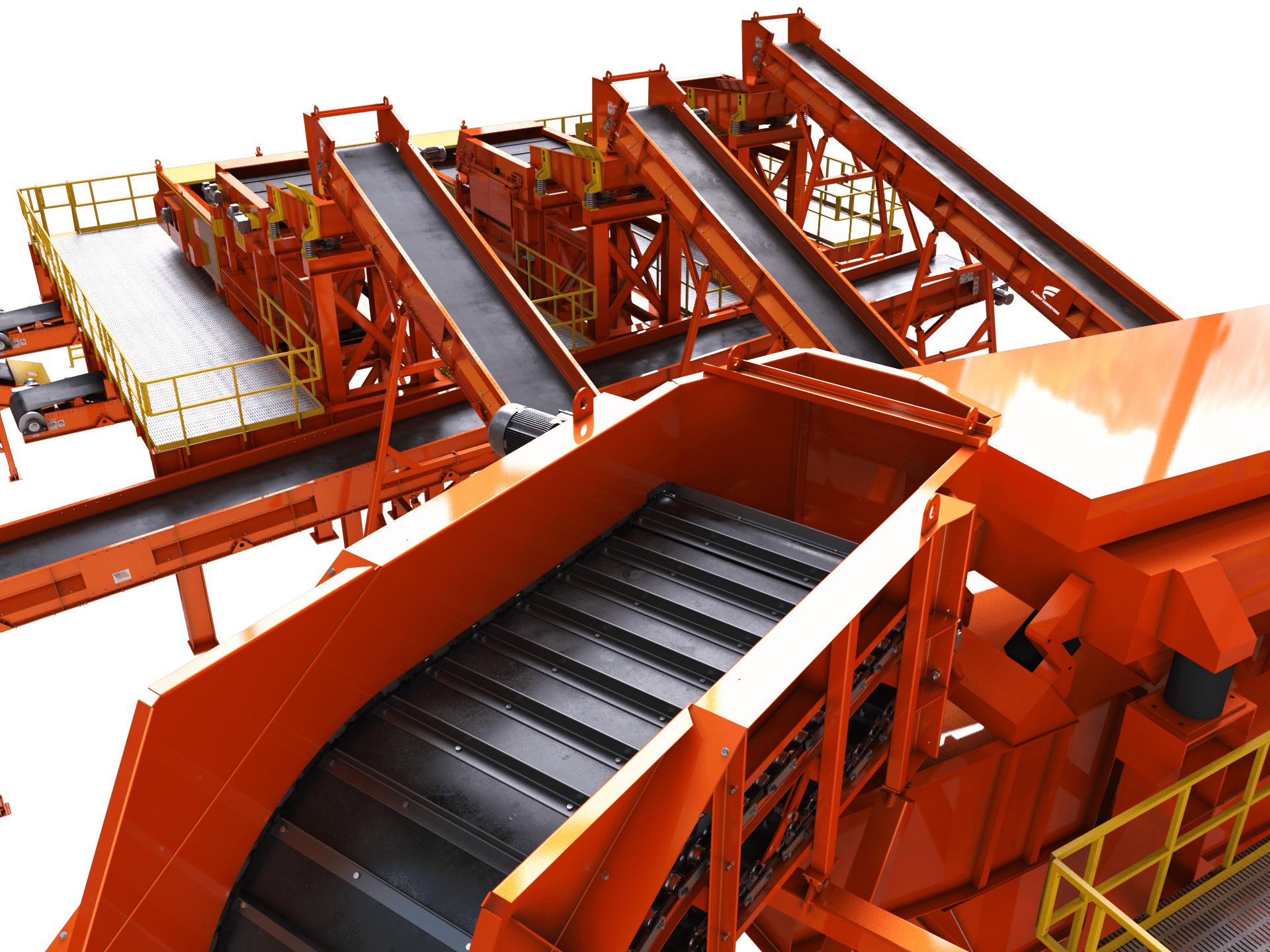

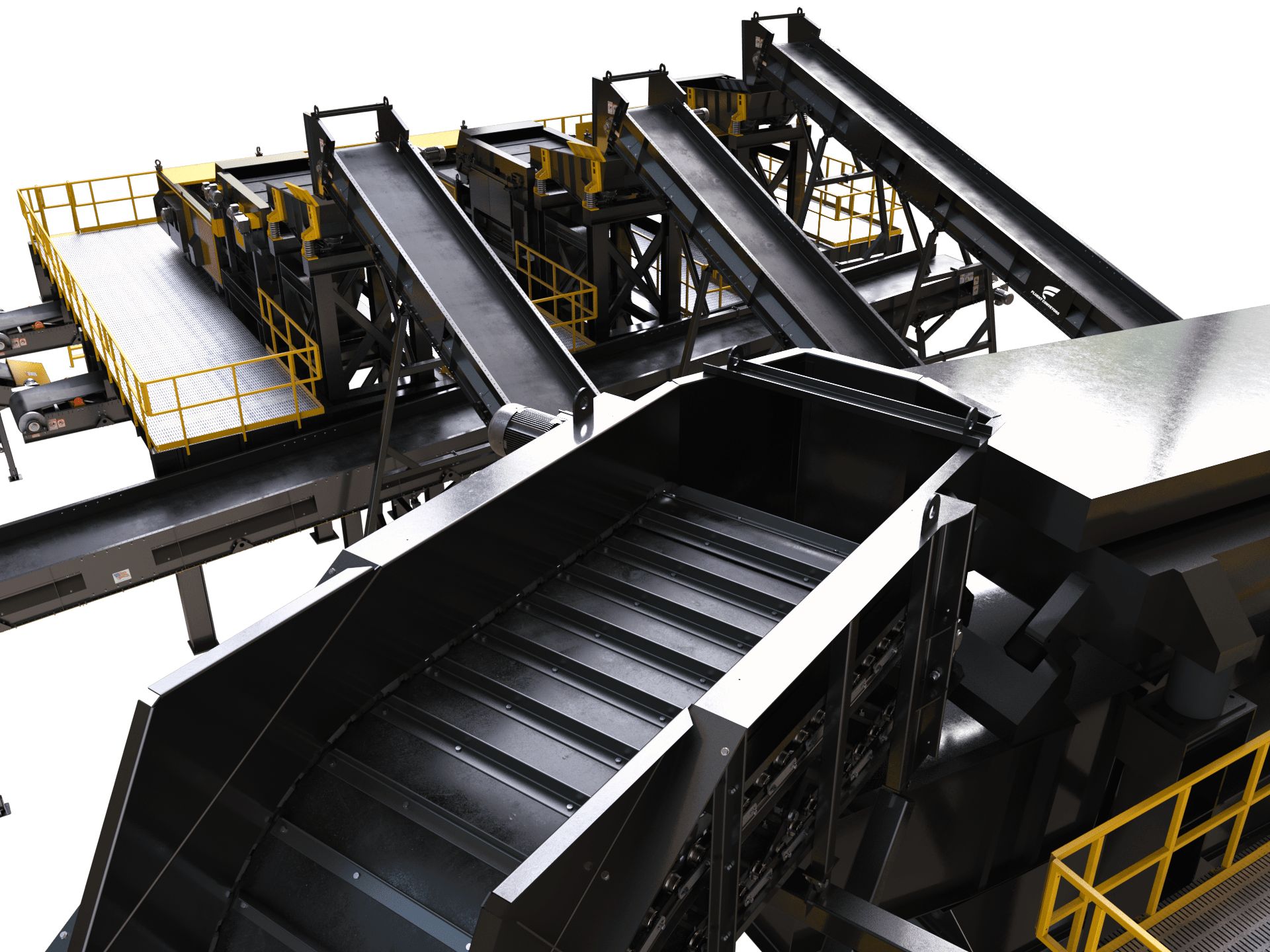

Fluent Conveyors can offer any color required to meet your project specifications. Please let a Fluent Conveyors employee know the RAL number for the paint as well as the paint manufacturer (Sherwin-Williams, PPG, Valspar, Diamond Vogel etc.).

Select Your Color

DIRECT SHAFT MOUNTED MOTORS & GEARBOXES:

Fluent Conveyors specs only premium components to complete our equipment and provide a high-quality solution. Fluent Specs Nord Gear Drive units for their quality reputation and exemplary products. Fluent Conveyors can use any specific manufacturer of motors/gearboxes upon request.

COLD ROLLED SHAFTS:

Fluent Shafts are made from cold rolled steel rod and turned to the tightest tolerances in the industry. Every shaft is made custom to fit your specific conveyor.

HEAVY DUTY BEARINGS:

Fluent Conveyors uses bearings that boast cast iron housing, wide inner races providing for larger load capacity than standard duty, B type seals for smooth function and protection against the elements, and the bearings are sized to greatly exceed L10 life hours for the machine load.

FLAME TREATED & HARDENED SPROCKETS:

Fluent Conveyors uses abrasive applications with high shock loading. The inherent strength and flame hardened teeth of these sprockets provide maximum service in the most severe environments. The versatility of flame cut sprockets allows for specialized designs for a variety of customer requirements.

What Customers Are Saying

"In 2018 our company was in a really weird position. We had purchased 2 large expensive conveyors over the last 5 years from 2 different manufacturers (Yes our application is rugged, heavy and has lots of baling wire). Both systems caused non-stop maintenance issues that were becoming very expensive for our company. We were referred to Fluent Conveyors by a local distributor/dealer in our area and from the start, I knew we found the correct manufacturer. Their pre-sales team visited our facility, took the time to listen to our core issues, and allowed our team to become part of the entire design process. I found their team slowing us down to re-validate key dimensions etc to ensure this new system would not only meet our expectations, but help position our capital layout to actually work for us for more than a couple of years. It has been almost 2 years and I can say the Fluent Conveyors team delivered exactly what we expected. No issues, 100% functioning and were are currently exploring adding a brand new system at one of our other facilities in 2020. Thank you for being professional and experts at your craft.

-John & Chris, Virginia

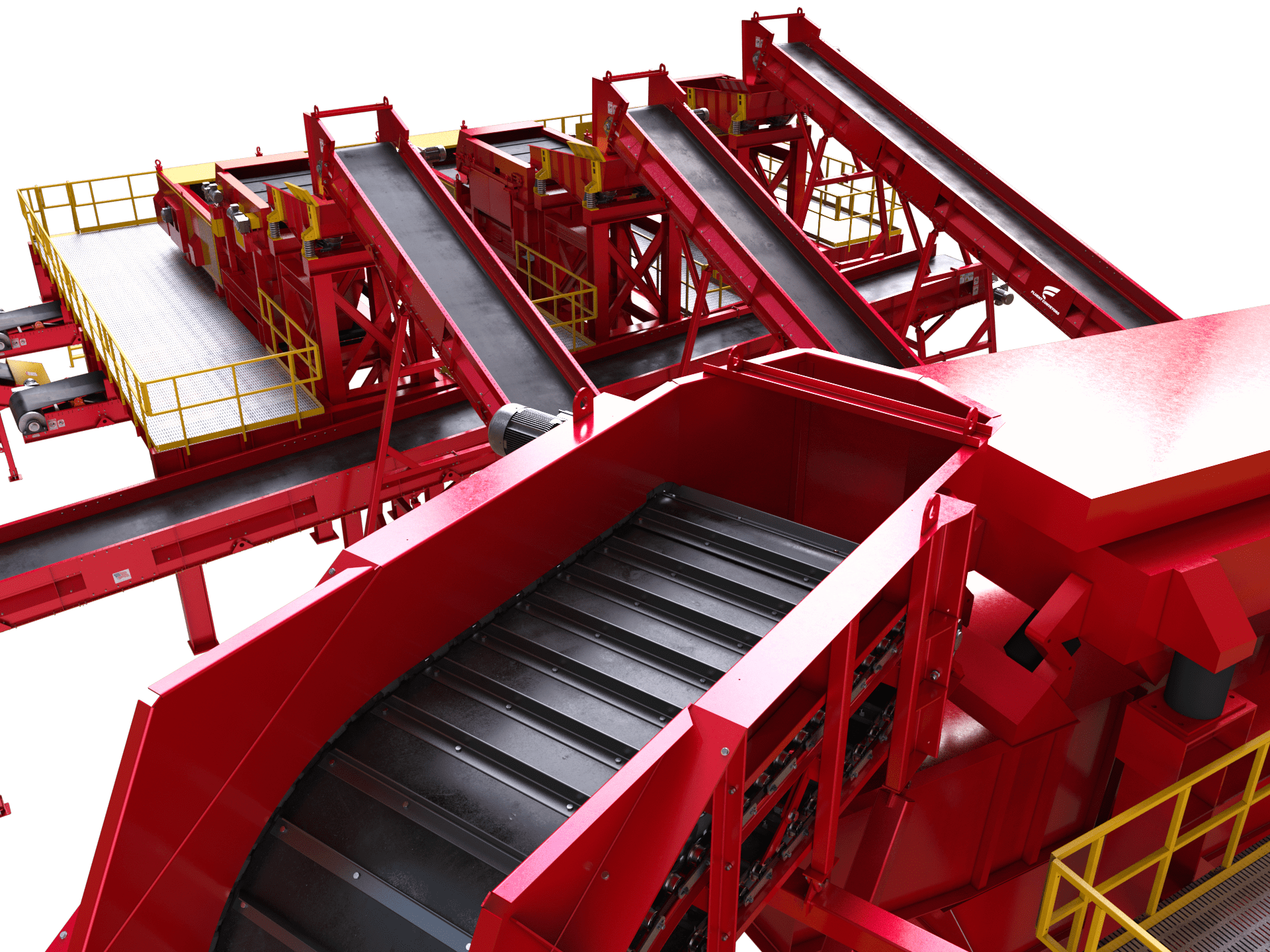

Getting Down & Dirty Pit Roller Chain Conveyor

Your instincts are right... You’re looking at the most robust series of conveyors we offer. Top-of-the-line engineering created with the industry’s highest manufacturing tolerances, our advanced RC Series delivers exactly what the market requires.

The Fluent Roller Chain Series is made to play in the big leagues. Fluent Conveyor’s Pit Infeed Roller Chain Belt Conveyors are found in robust applications and best utilized for new and existing pits.

This model delivers exactly what the market requires for high volume rigid and abrasive material as well as high-temperature and other extreme applications. All designs are made to order and customizable. This model requires 3/8-inch-thick or 1⁄2 -inch-thick pit plates and material is typically fed onto the conveyor with a skid steer, bobcat, front-end loader etc. Only the best machinery, transforming your systems and business.

The Above Ground Roller Chain Conveyor

The above ground roller chain conveyor is created to drastically increase productivity and keep your business running at an optimal pace.

This series of conveyors is the most robust series of conveyors we offer. This model delivers exactly what the market requires for high volume rigid and abrasive material as well as high-temperature and other extreme applications. All designs are made to order and customizable. You will always get the perfect machinery for your unique needs.

This model is available in inclined, flat, L and S shapes to fit all types of applications. This model is guarded with expanded metal on the lower horizontal (loading area) to allow for visual inspections of clean-liness and function. Flawless engineering for flawless performance.

Detailed & Customized Mechanical Engineering

FLUENT CONVEYOR DESIGN GUIDELINES

Fluent Conveyors Roller Chain Series Conveyors are designed with cutting edge software to be ahead of the curve. Giving you an edge above the rest. All machinery is validated using premium 3D CAD software and manufactured to industry leading tolerances and standards. After completion of a design, the engineering team releases to quality assurance, allowing secondary engineers to validate critical dimensions, calculations and manufacturability. After initial and secondary engineering approvals, projects are released to purchasing and the manufacturing facility by the lead manufacturing engineer. Our experts only approve the highest caliber work to ensure you’re working with nothing but the best.

FLUENT CONVEYOR MANUFACTURING GUIDELINES

Fluent Conveyors Roller Chain Series conveyors are made in innovative facilities to equip you to level up your business. With all the industry leading equipment and processes, Fluent Conveyors production team has over 100 years of combined experience paired with a facility of more than 85,000 square feet. The core facility has a paint booth, 40,000 square feet of dedicated assembly, 6 – welding stations, CNC fabrication equipment, 10 – overhead cranes and more. Parts are cut/machined on CNC Routed machines and bent on CNC Brakes for the best in industry tolerances. Every weld is tacked and re-measured for accuracy then completed by the staff of certified welders. Once manufactured, every conveyor passes through a 3-step finishing process ending with high grade paint. Ensuring you’re working with smart, flawless machinery.

CONVEYOR TESTING OVERVIEW

All conveyors are delivered to you ready for work. Assembled and released to a detailed quality assurance checklist to make sure your machinery can hit the ground running. This includes key validations such as; weld examination, sub-assembly QC, 10 hours of tested run time, head shaft height validation, frame levelness, frame width validation, overall height/length, belt speed, belt tracking, belt and conveyor alignment, electrical requirements, incline and nose over angle verification and all other major specifications. Making sure your machinery is set up for long term success.

SHIPPING OVERVIEW

We ship the smartest way possible, to make your job easy. Fluent Conveyors Product shipments are carefully planned in CAD software to be loaded in an organized, space saving, and safe manner ensuring that all products arrive on-site the same as when they left our facility. Loose items are boxed and marked, assembled parts and components tightened to endure the rigors of freight and shipping. We’re here to make sure every step of the process is seamless.

We can build panels of any size and up to 480VAC/600VAC (Canada), maybe more on a case by case basis.

Additional support / Controls support:

- FAT and SAT (factory or site acceptance testing)

- Remote support over the phone

- Functionality/Design change based on process changes

- Operational training

- Troubleshooting training

- PLC programming (Rockwell)

- Integration into existing SCADA/PLC (case by case basis)

As well as producing bespoke conveyor systems, we also supply custom replacement belts and parts to ensure no client sees their assembly line stay offline for an extended period of time. From replacement motors to sprockets, everything is covered if a client comes across a failing element of their conveyor system.

Sadly, it’s inevitable your clients will face some type of issue with their conveyor system at some point. Even with Fluent Conveyors’ best equipment in place, conveyors are going to suffer from wear and tear due to their demanding nature. However, being able to offer a solution at any time will be appreciated by your clients.

Are You Ready To Schedule Some Time With The Fluent Conveyors Team? Great!

Our Process Is Typically Very Lean & Detailed! We Prefer Not To Waste Our Customers Time! Engineering Time & Revisions Takes A Considerable Amount of Time For Both Customers & Our Engineering Team.

Please Contact Us If the Roller Chain Conveyor Specifications Match What You Need & You Are Comfortable With:

- Price Can Range From $40,000 - $450,000 Per Conveyor

- Lead Time of 10 – 12 Weeks (From Down Payment & Signed Approval Drawings)

- Pre-Payment on Engineering Time if The Project is Complex

- 50% Down-Payment, 40% 2 Weeks Prior To Ship, 10% Net 30 Upon Install

-

What options are offered with the custom sort?

Fluent Custom Sort Stations offer almost everything you could need. The goal is to match the sorting process and make everything as efficient as possible for your facility. We offer OCC screens, glass breakers, optical sorters, eddy currents, magnets, ballistic sorters, robotics, trommels, live bottom bins, balers and more!

This series of conveyors requires a down-payment of $20,000 before any type of engagement occurs. This is labor extensive to our engineering department and we don’t want to waste anyone's time.

If you are ready to start the process and have $20,000 to begin the process, please contact our sales team.

-

How is recycled material sorted?

Sorting waste and recycling has all different approaches. You can sort manually and you can also leverage technology to help reduce labor and automate.

The core goal when sorting recyclables is to reach 99% clean or better on the final sorted materials for export. This is best accomplished by removing bulky materials first and implementing as many systems and technologies to automate removal of smaller materials without the cost of labor down-stream.

Current transitions in these types of systems include implementation of robotics, optical sorters, magnets, eddy currents etc. to reduce error and increase efficiency.

-

What is the risk if I purchase this type of system?

This is a very capital extensive purchase so there are a few key things to consider when calculating your ROI for a sorting system.

· Cost of the system

· Installation costs

· Delivery Costs

· Material volume, cost to process and the sales price and volatility of the material

· Export processes and what must be done to ensure your material is acceptable

· Market changes and requirements

· Employment of key personnel to correctly manage and run the facility

· Maintenance and repair costs per piece of equipment

The biggest goal is to make sure you have the correct outlets for your material. That allows you to remain profitable during the market cycles. Invest in a modular system that allows you to add on and grow with automation vs being stuck with overkill or expensive assets that are not giving you a return on your investment.

-

Can I have screens, magnets and optical sorts with the custom sort?

Yes. Fluent Conveyors custom sort systems are fully customizable. You can be fully automated or totally manual, as well as any combination in between. We can integrate sorting equipment from ballistic separators to cross belt magnets to optical sorters and anything in between.

-

How do I know this will fit into my facility?

Contact the Fluent Conveyors sales team and we can work on general dimensions of the system and your building before we get started. Upon the $20,000 down payment you will receive concept designs and layouts. Fluent will go through these with you to ensure they will both meet your needs and fit in your building.

-

What options are offered with the custom sort?

Fluent Custom Sort Stations offer almost everything you could need. The goal is to match the sorting process and make everything as efficient as possible for your facility. We offer OCC screens, glass breakers, optical sorters, eddy currents, magnets, ballistic sorters, robotics, trommels, live bottom bins, balers and more!

This series of conveyors requires a down-payment of $20,000 before any type of engagement occurs. This is labor extensive to our engineering department and we don’t want to waste anyone's time.

If you are ready to start the process and have $20,000 to begin the process, please contact our sales team.

-

How is recycled material sorted?

Sorting waste and recycling has all different approaches. You can sort manually and you can also leverage technology to help reduce labor and automate.

The core goal when sorting recyclables is to reach 99% clean or better on the final sorted materials for export. This is best accomplished by removing bulky materials first and implementing as many systems and technologies to automate removal of smaller materials without the cost of labor down-stream.

Current transitions in these types of systems include implementation of robotics, optical sorters, magnets, eddy currents etc. to reduce error and increase efficiency.

-

What is the risk if I purchase this type of system?

This is a very capital extensive purchase so there are a few key things to consider when calculating your ROI for a sorting system.

· Cost of the system

· Installation costs

· Delivery Costs

· Material volume, cost to process and the sales price and volatility of the material

· Export processes and what must be done to ensure your material is acceptable

· Market changes and requirements

· Employment of key personnel to correctly manage and run the facility

· Maintenance and repair costs per piece of equipment

The biggest goal is to make sure you have the correct outlets for your material. That allows you to remain profitable during the market cycles. Invest in a modular system that allows you to add on and grow with automation vs being stuck with overkill or expensive assets that are not giving you a return on your investment.

-

Can I have screens, magnets and optical sorts with the custom sort?

Yes. Fluent Conveyors custom sort systems are fully customizable. You can be fully automated or totally manual, as well as any combination in between. We can integrate sorting equipment from ballistic separators to cross belt magnets to optical sorters and anything in between.

-

How do I know this will fit into my facility?

Contact the Fluent Conveyors sales team and we can work on general dimensions of the system and your building before we get started. Upon the $20,000 down payment you will receive concept designs and layouts. Fluent will go through these with you to ensure they will both meet your needs and fit in your building.