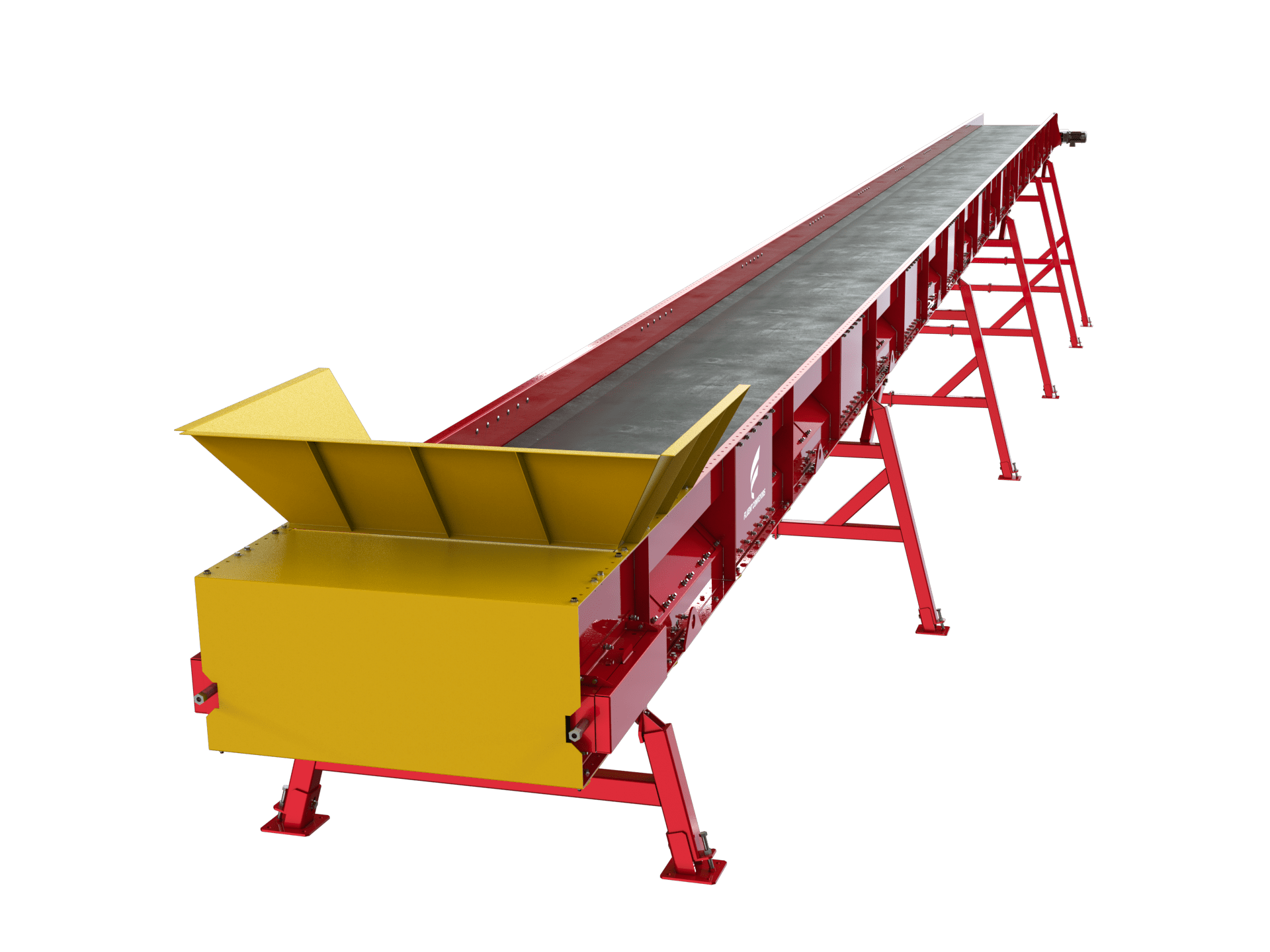

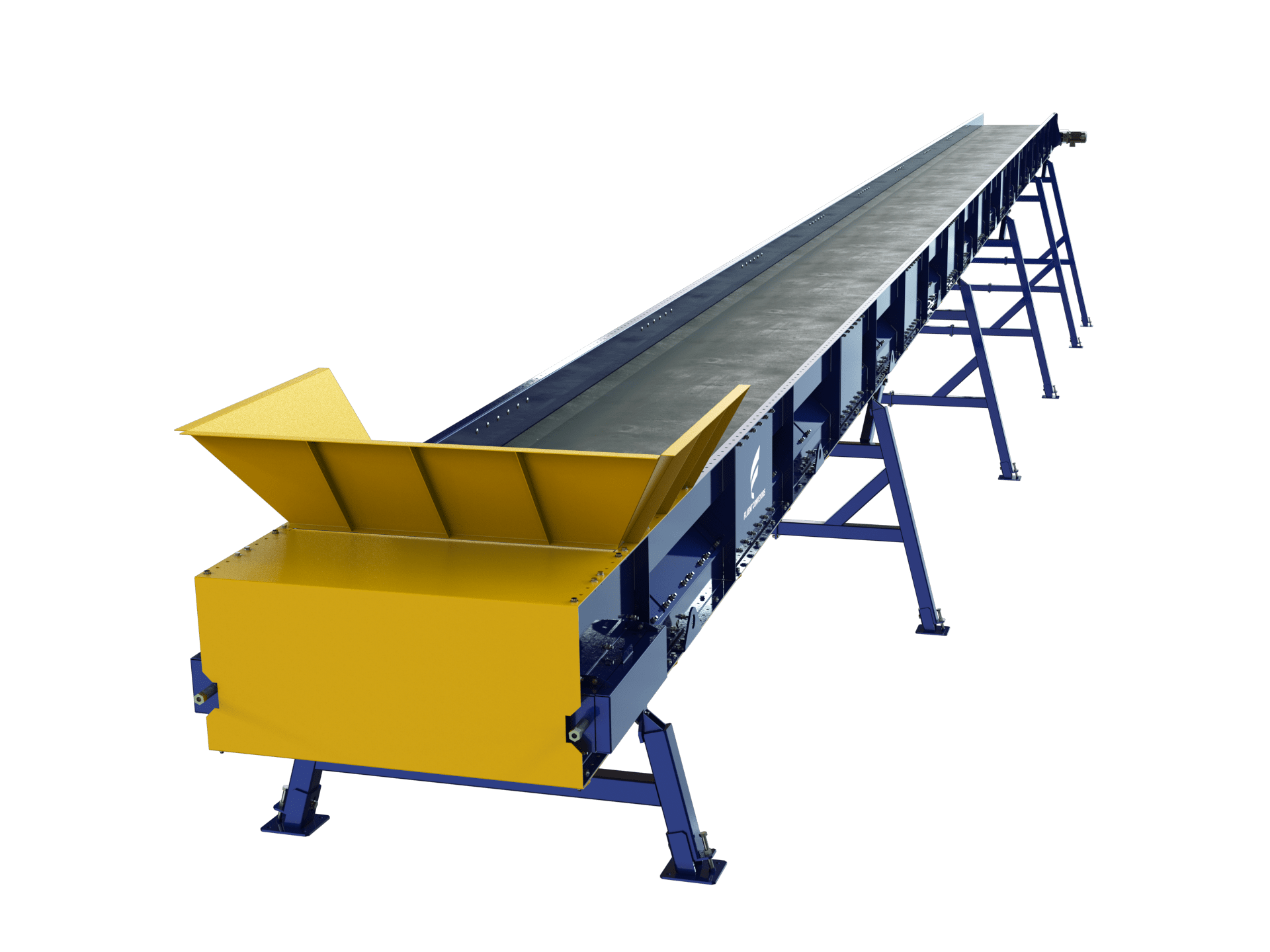

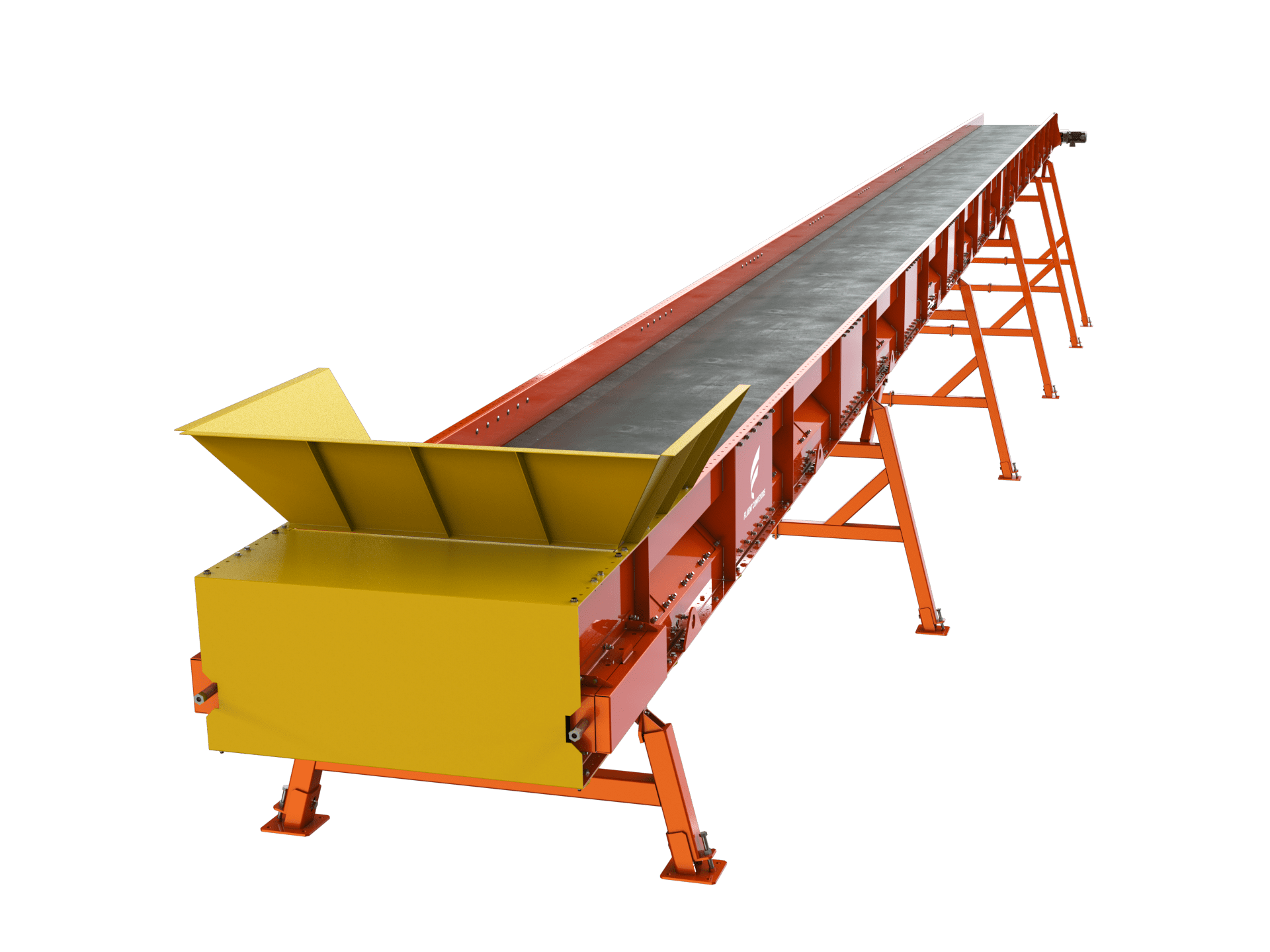

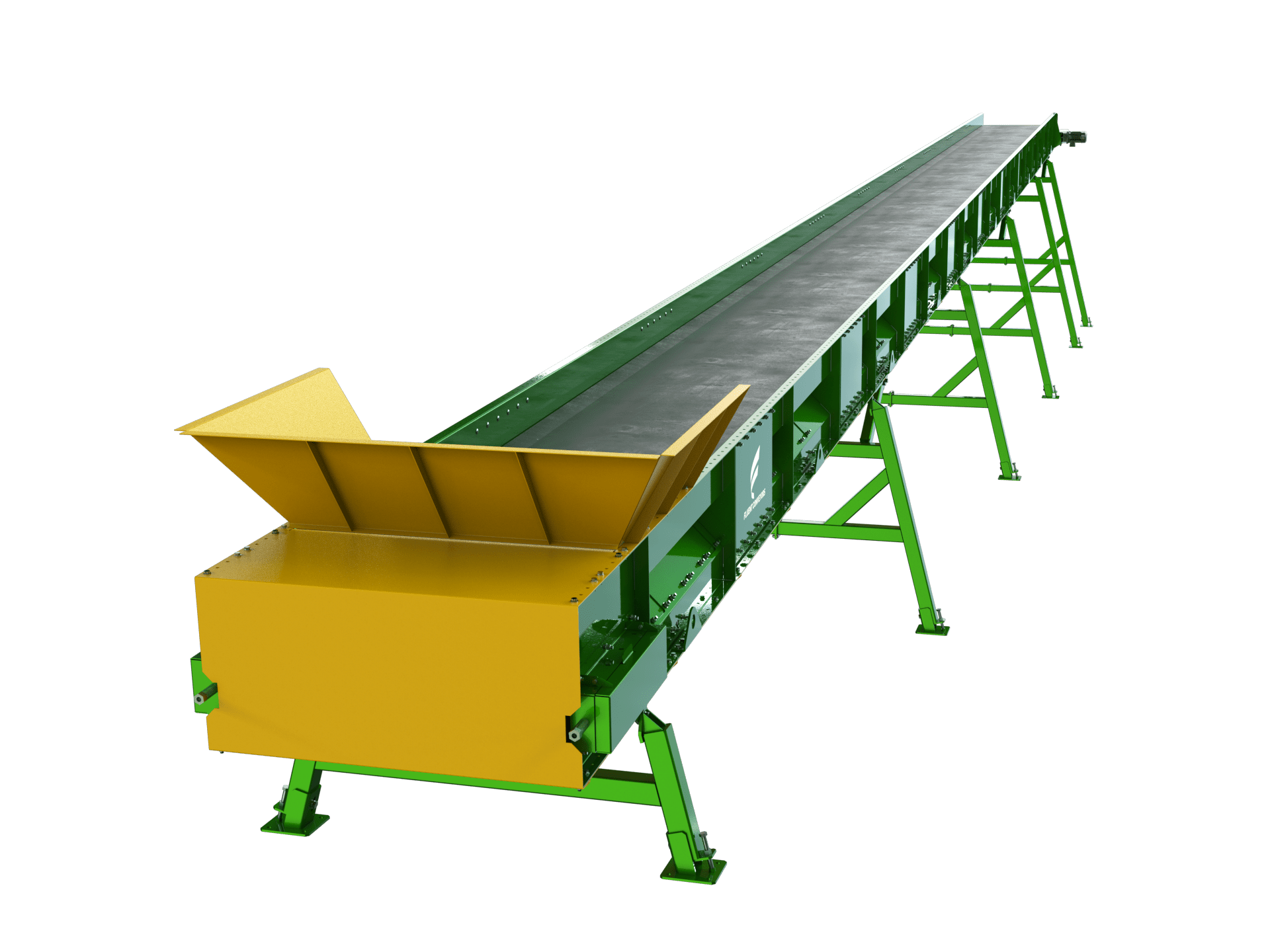

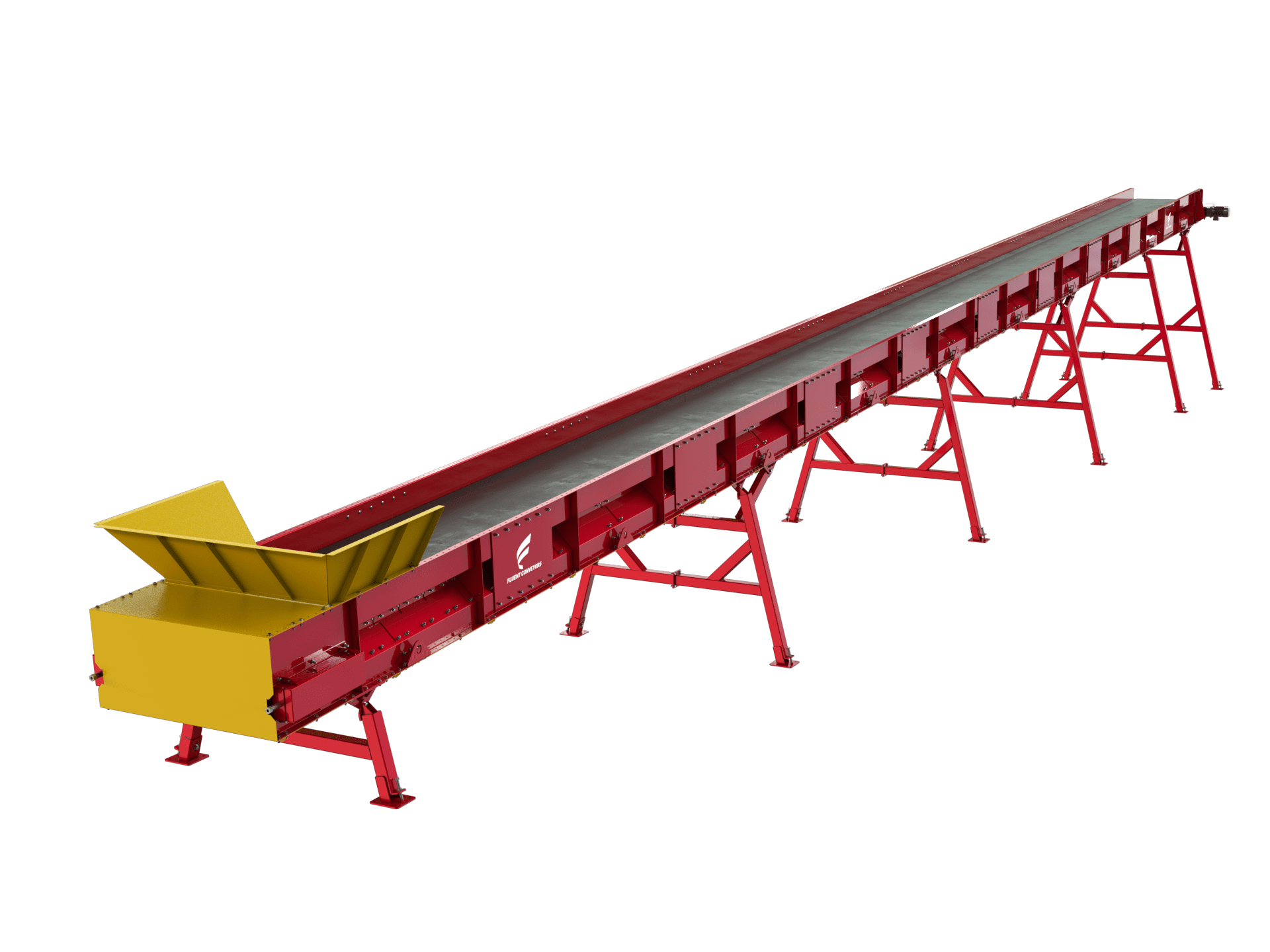

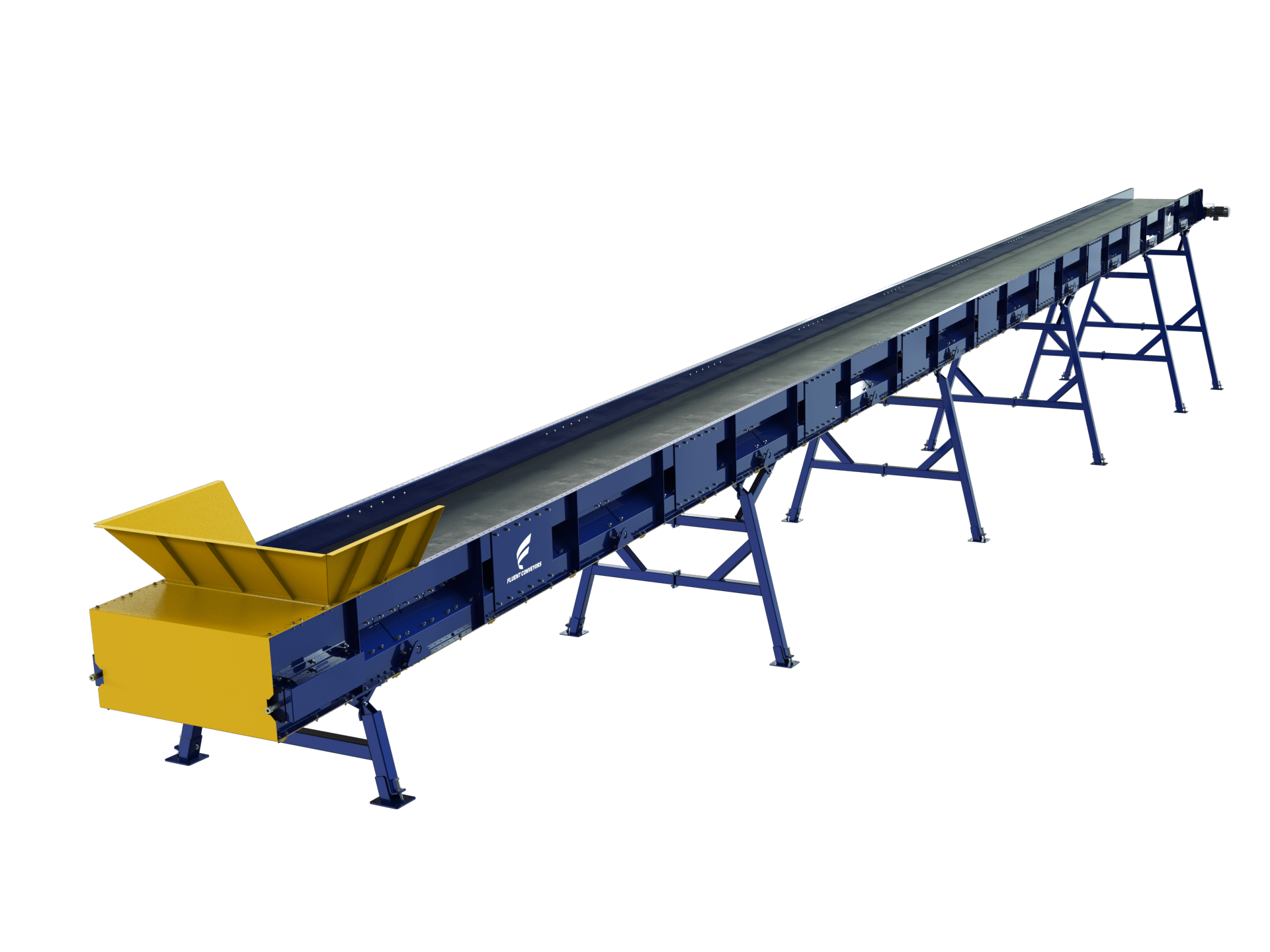

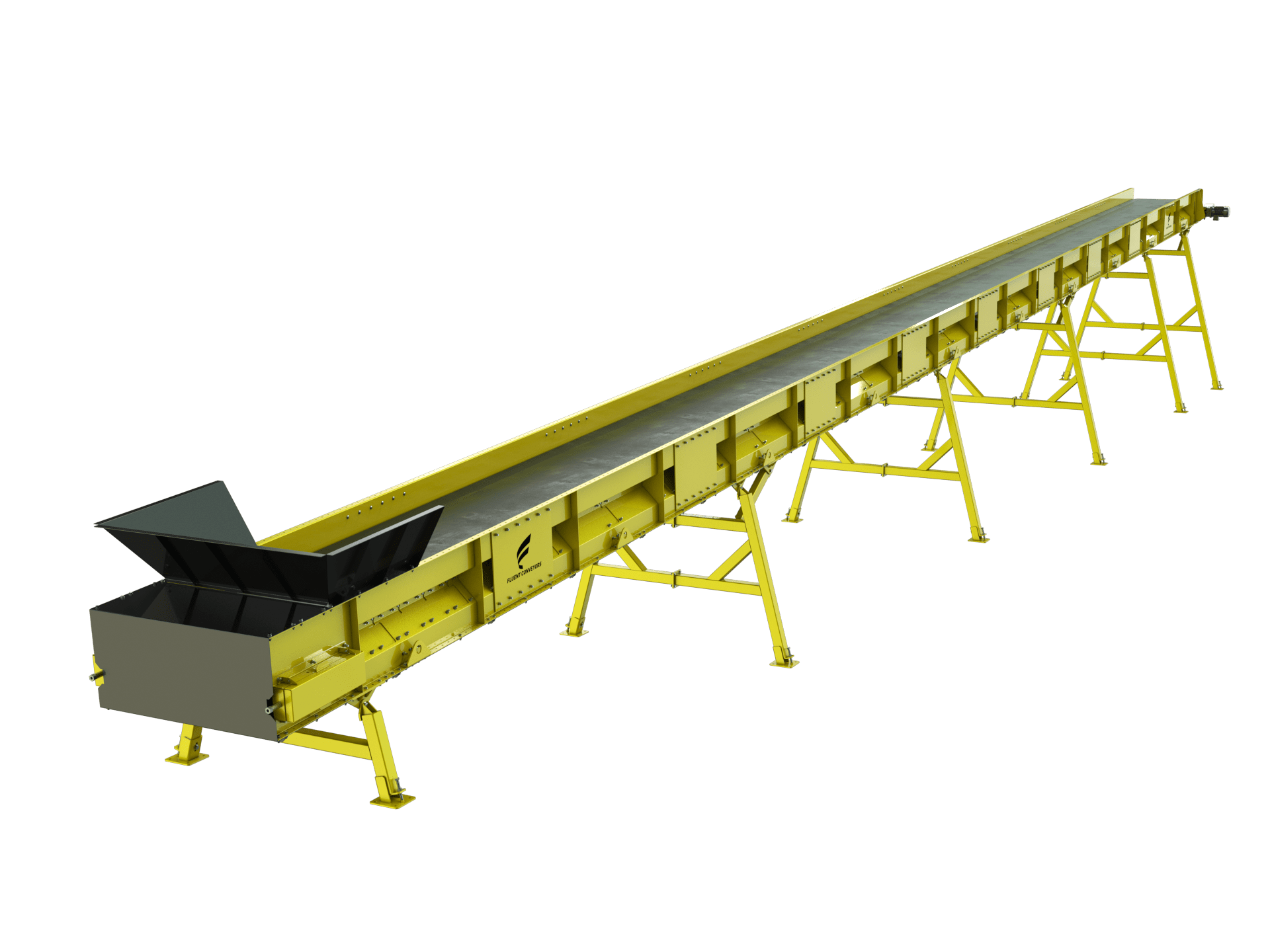

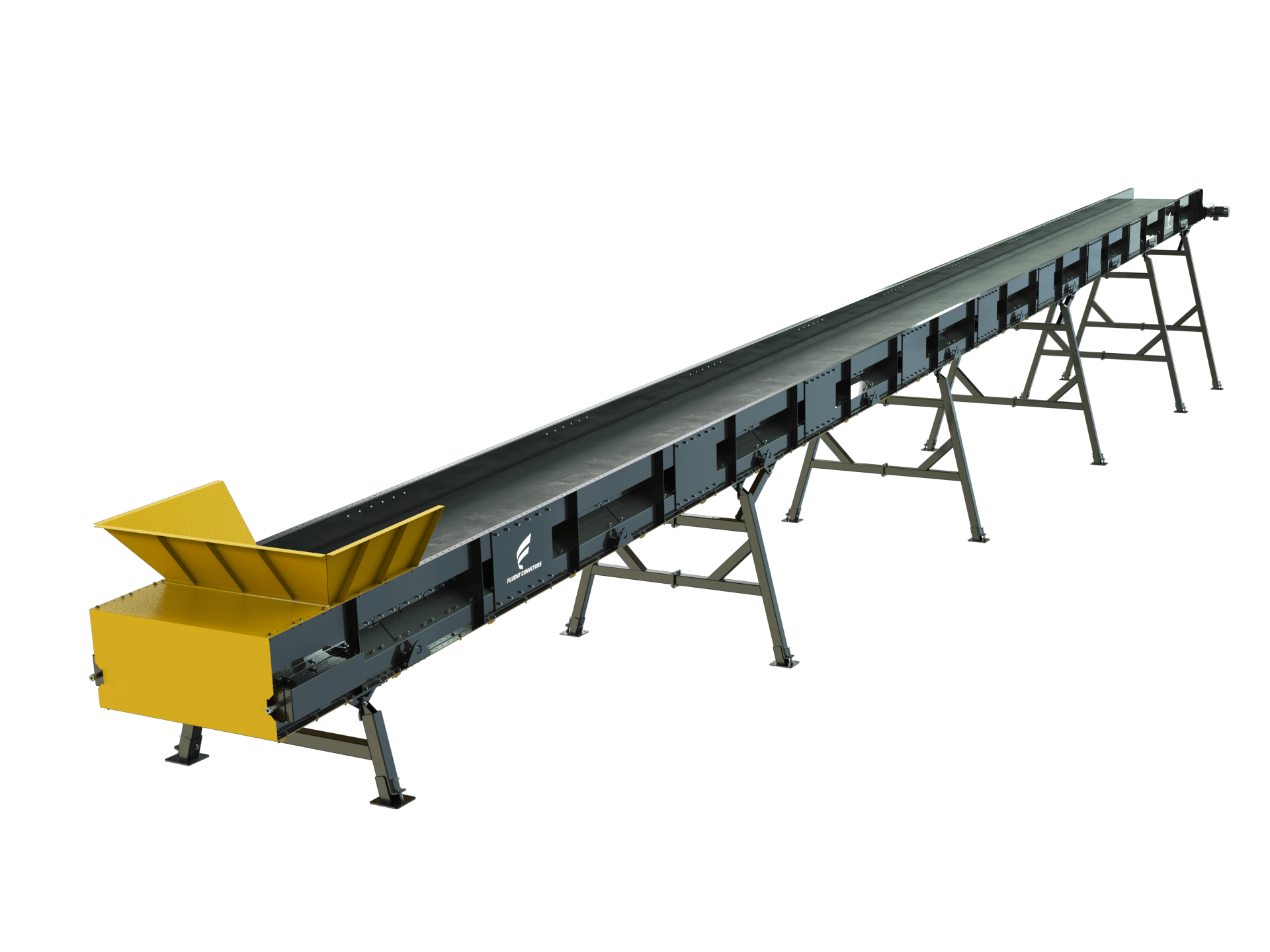

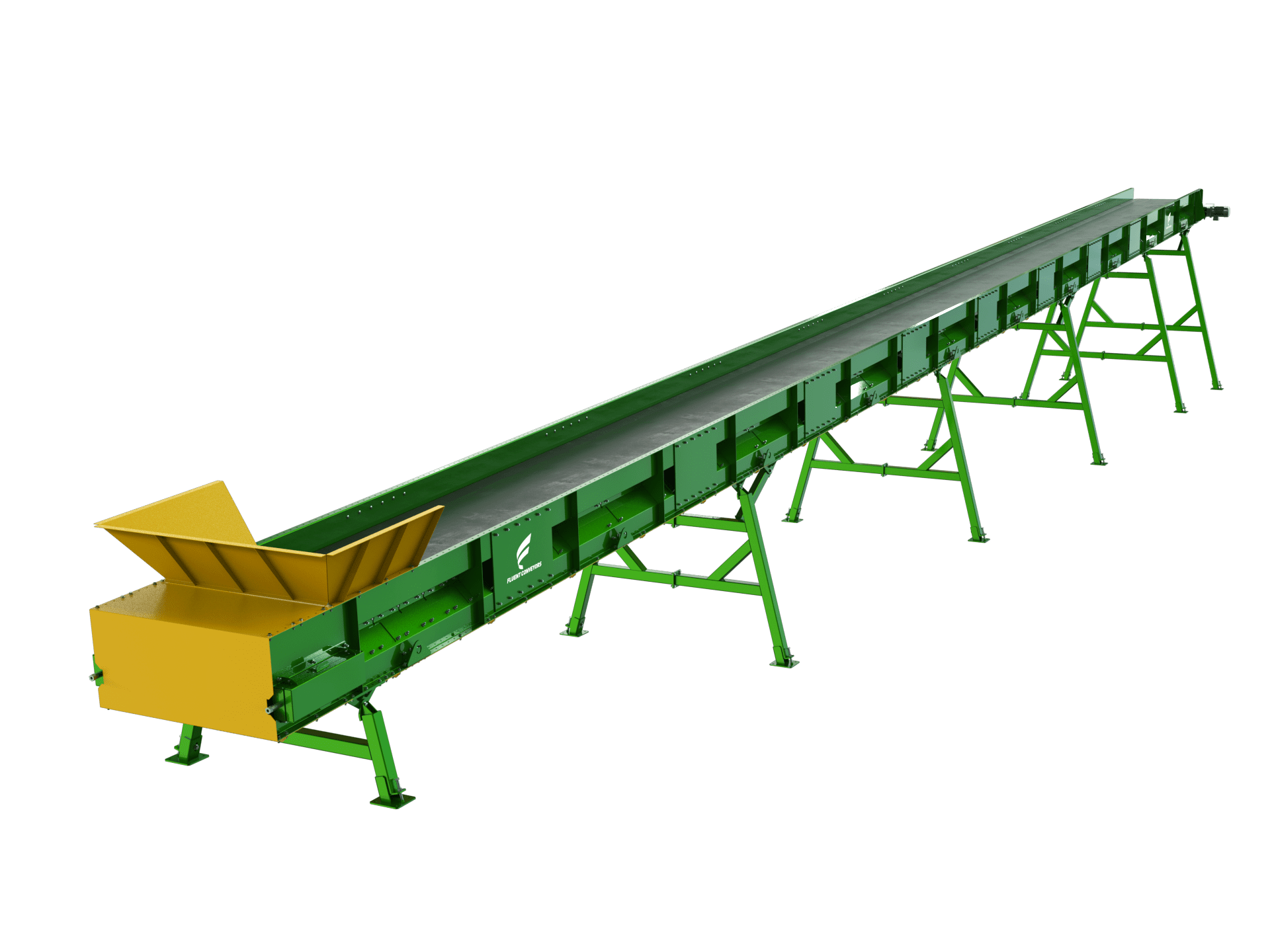

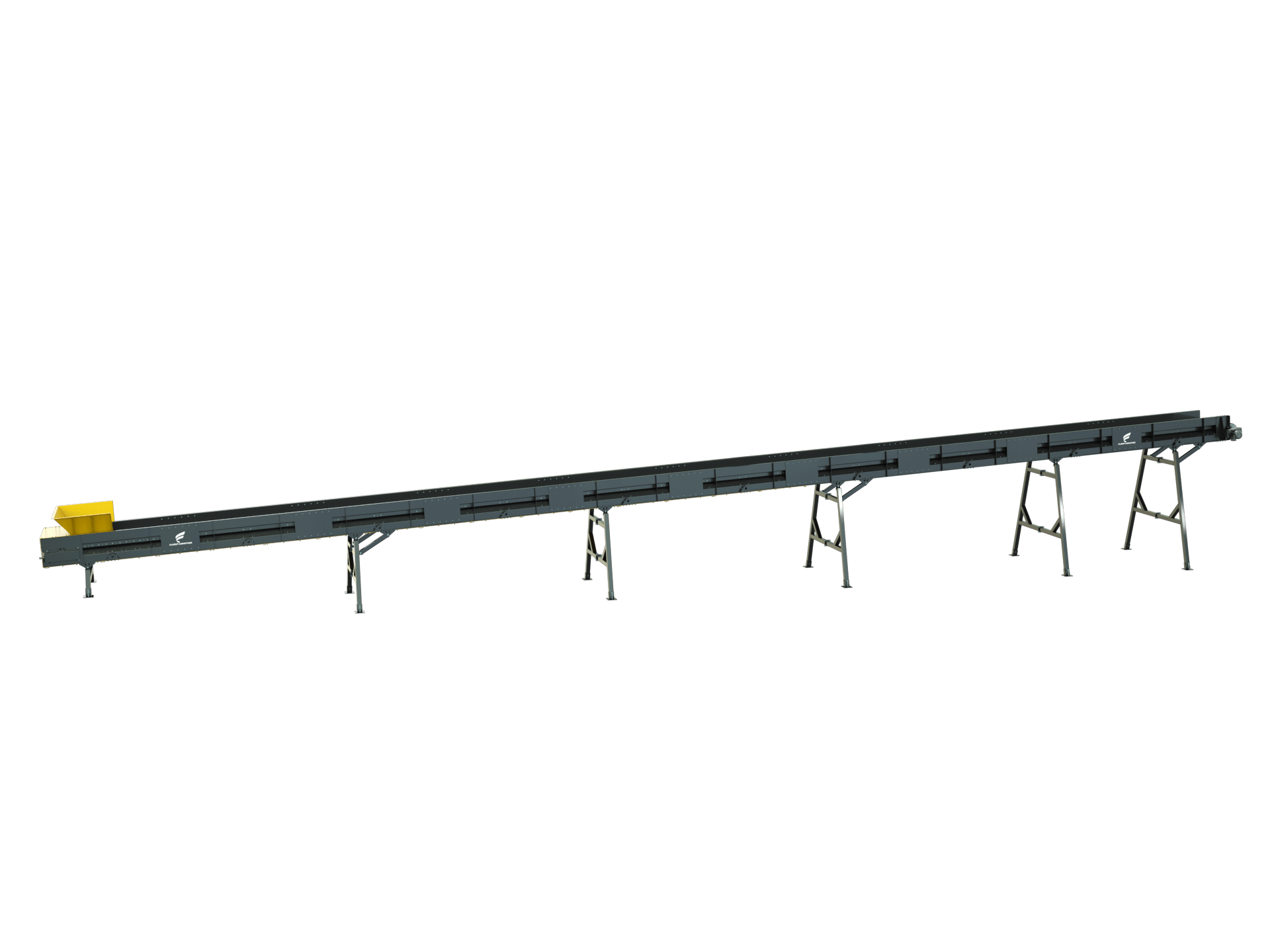

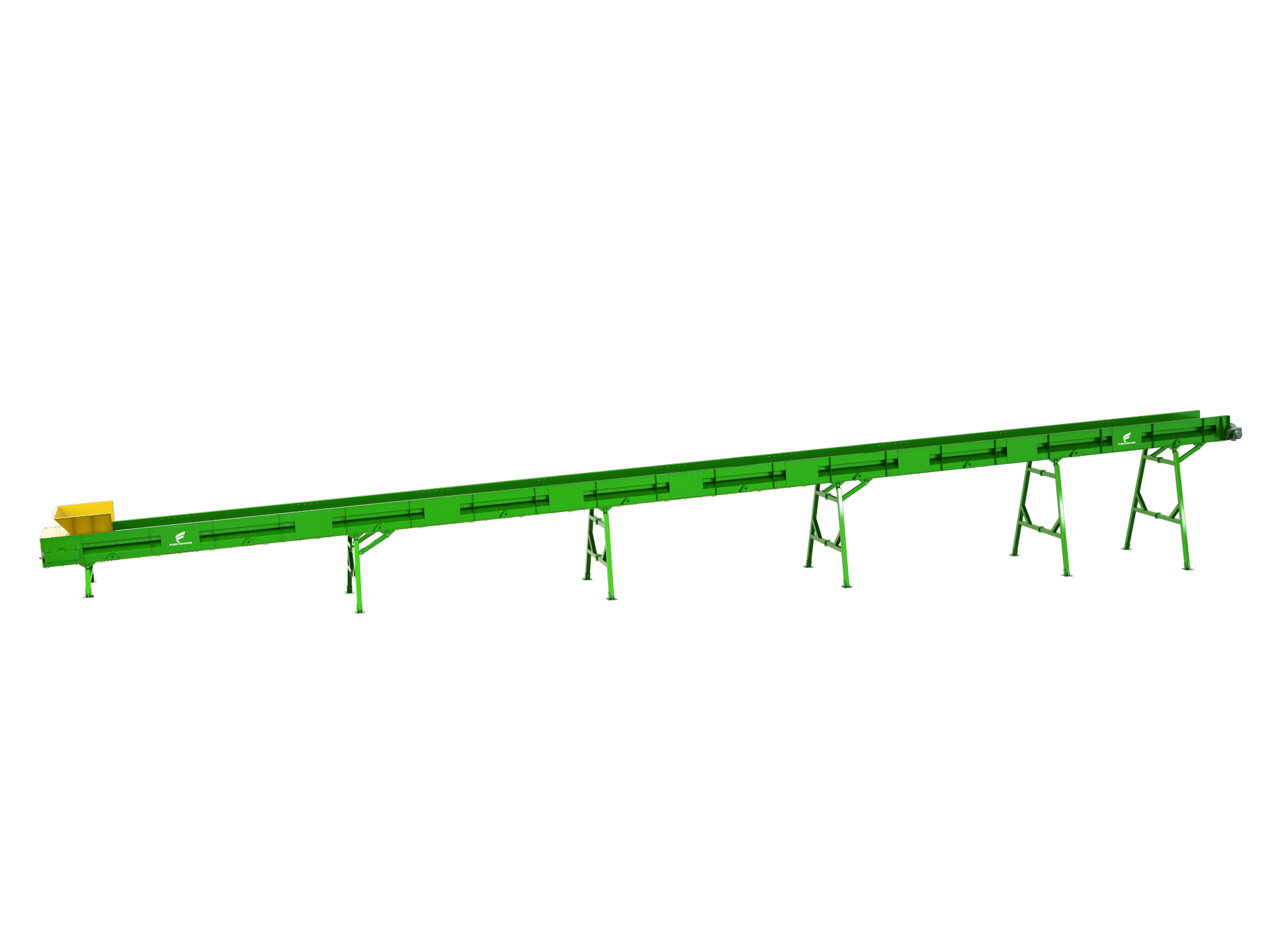

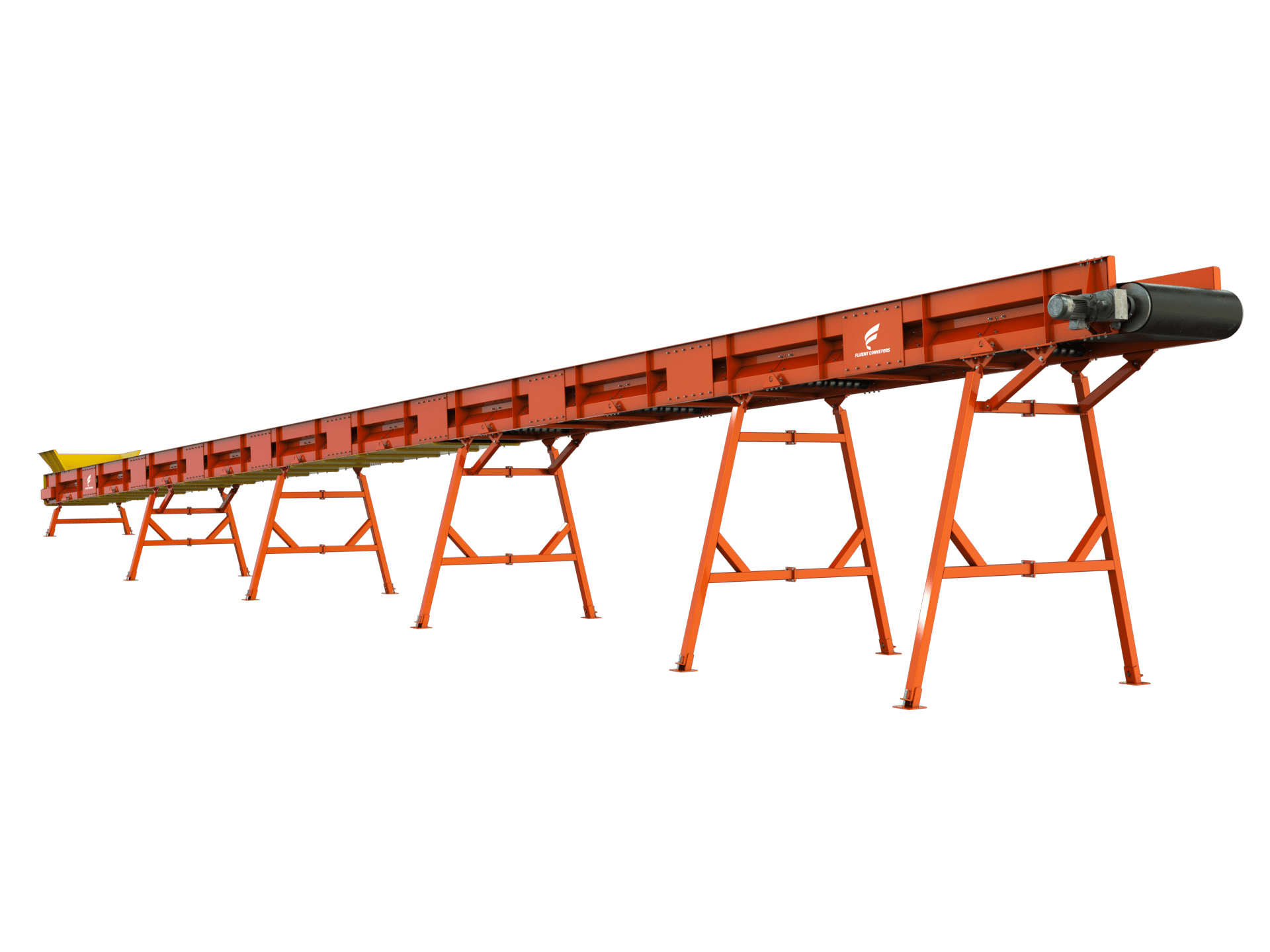

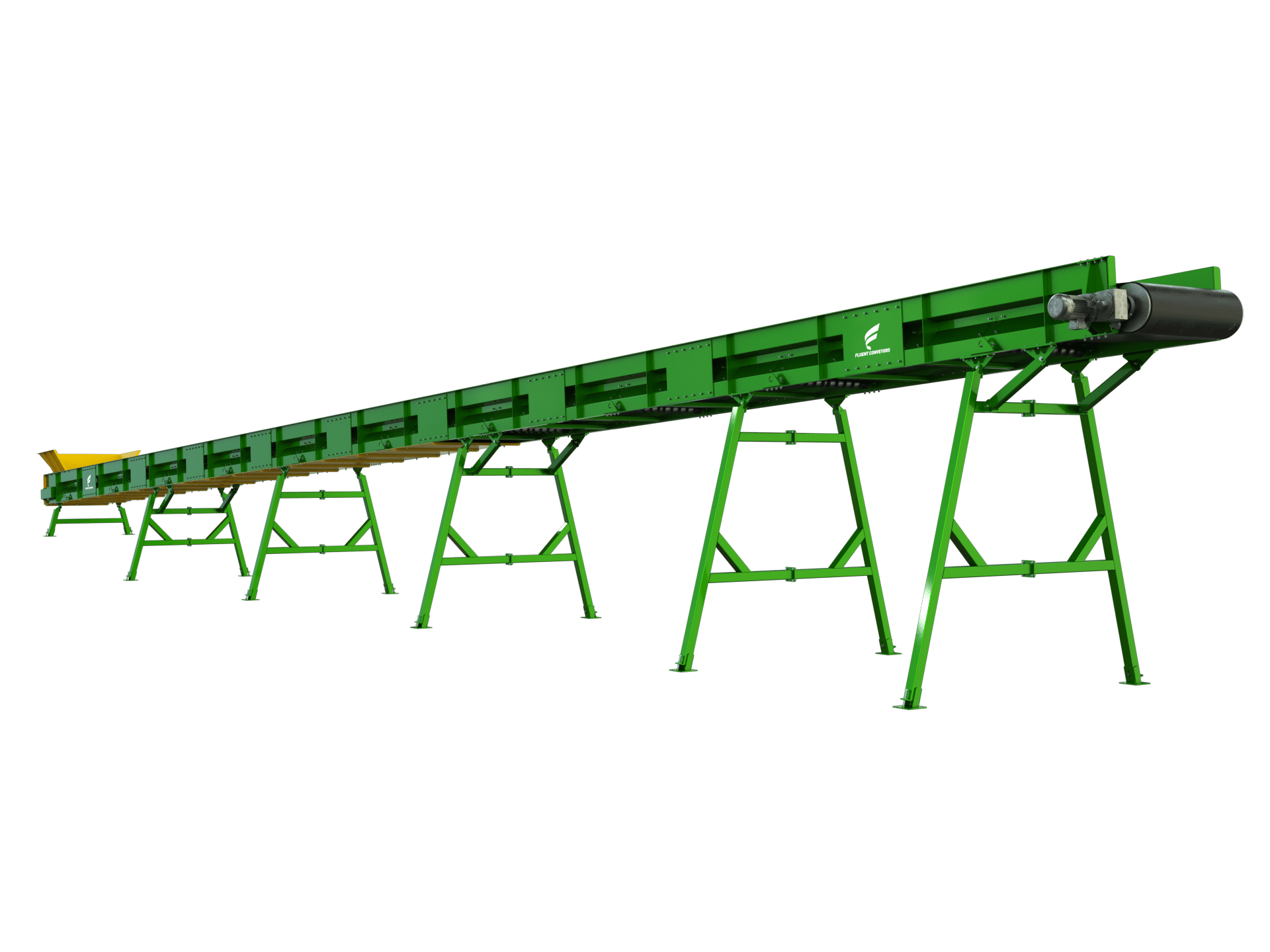

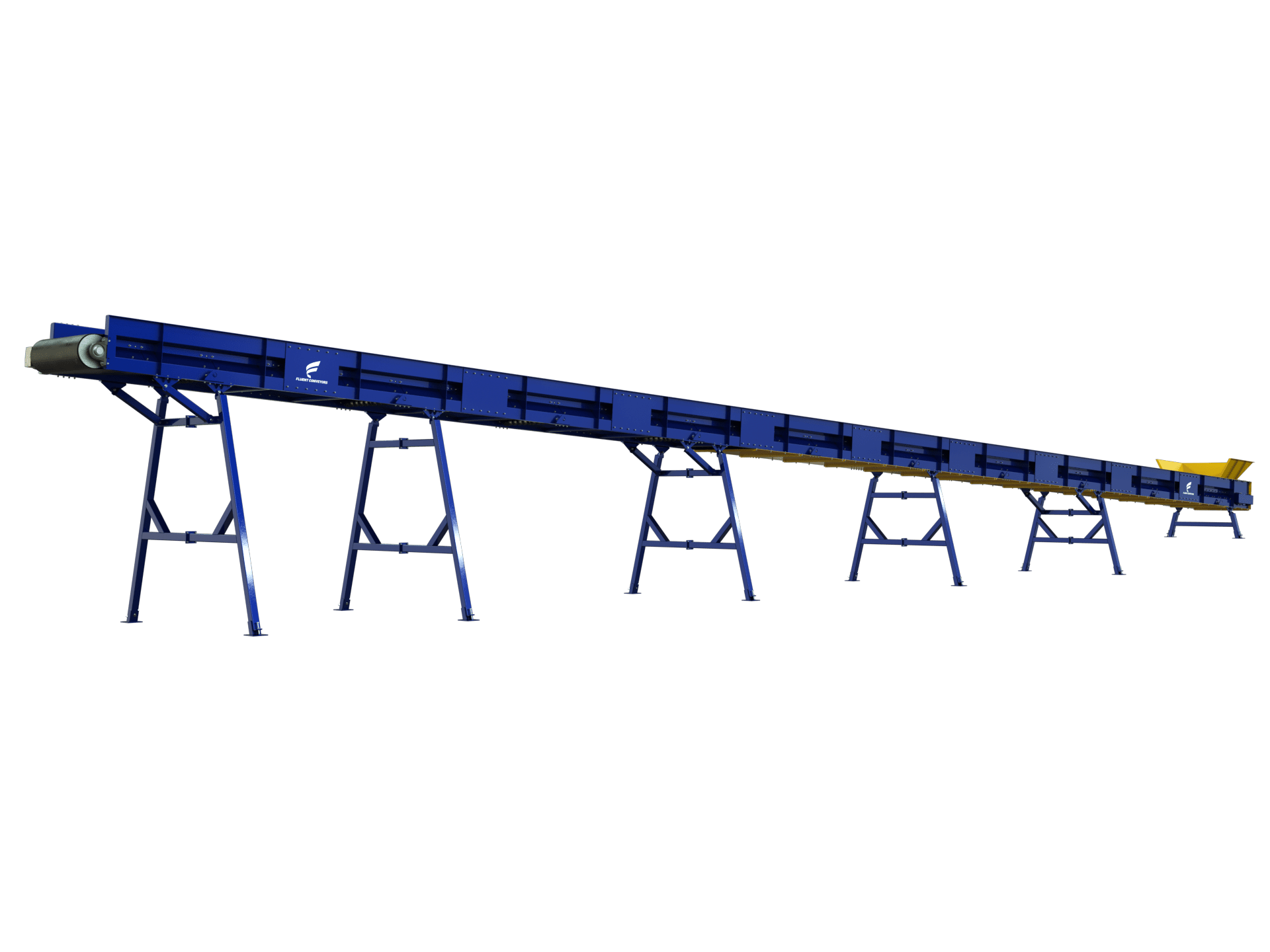

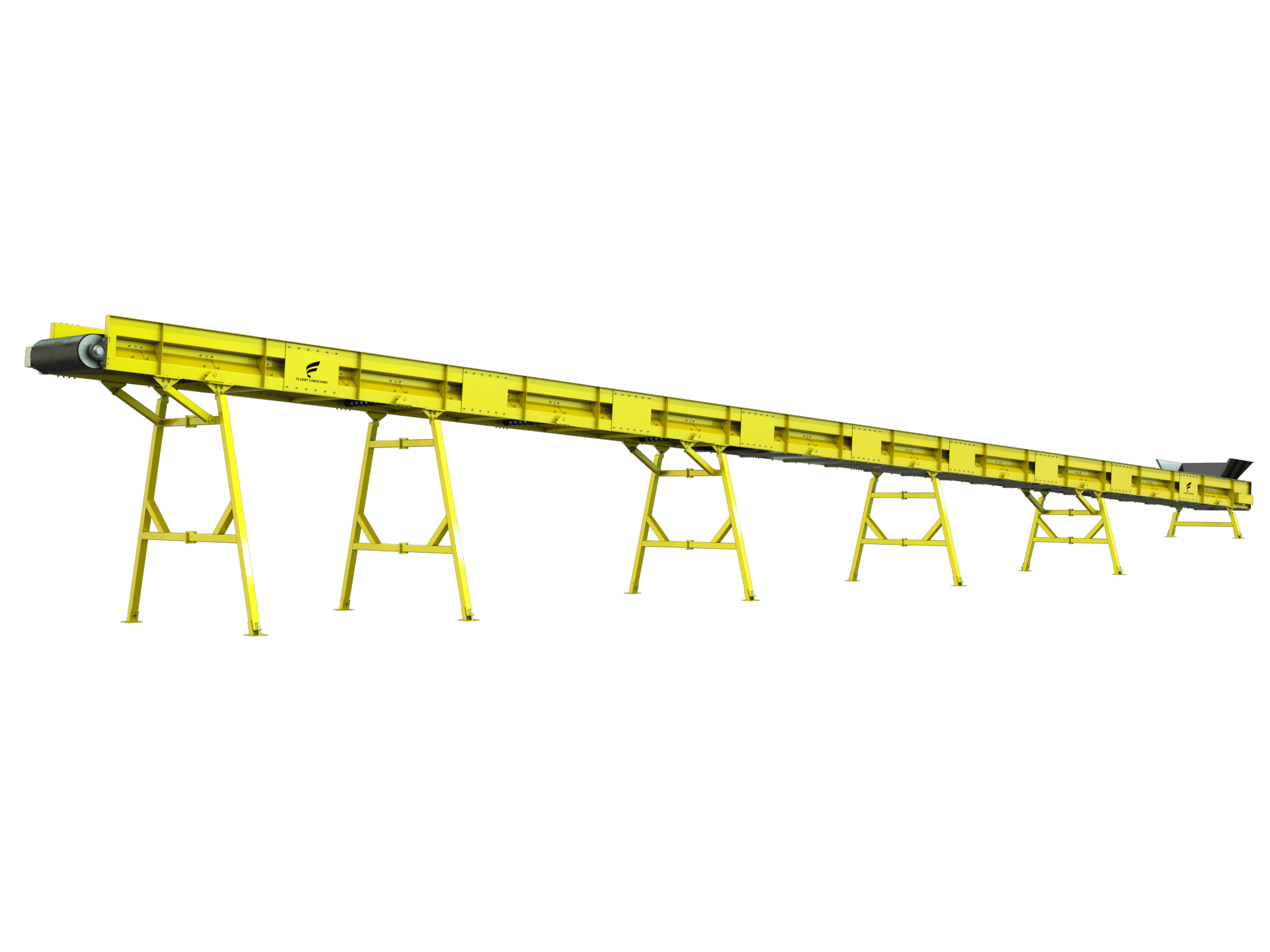

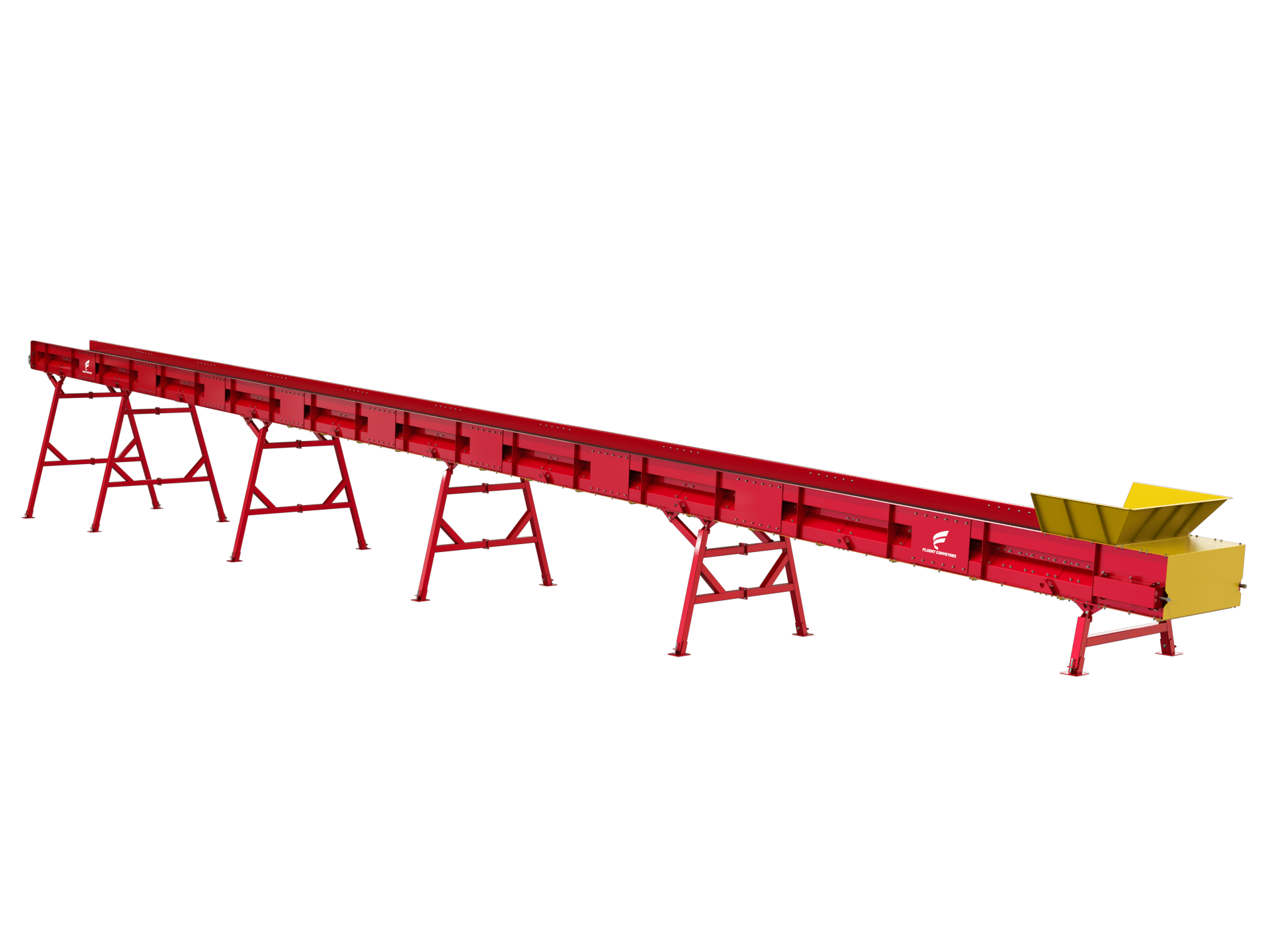

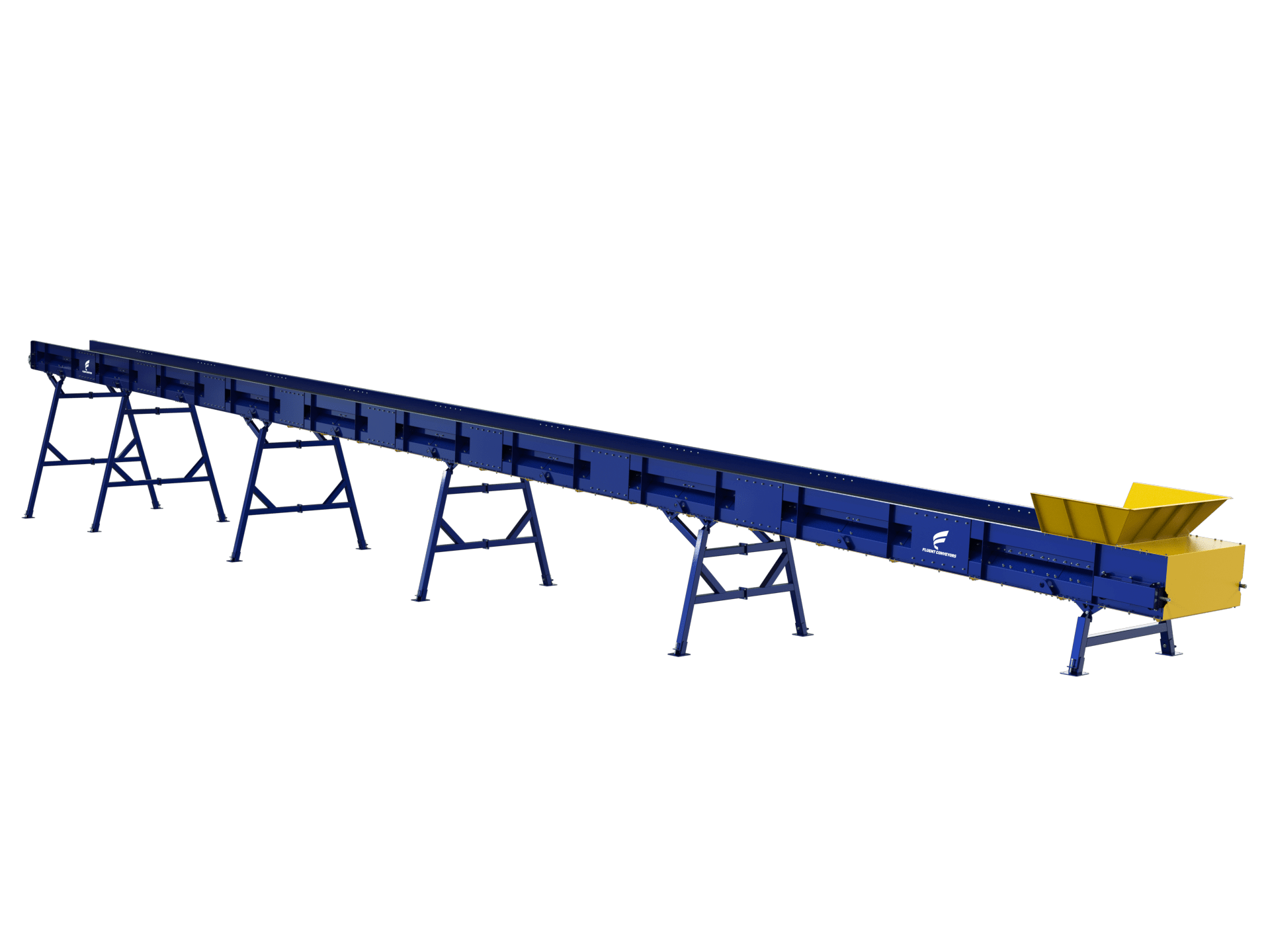

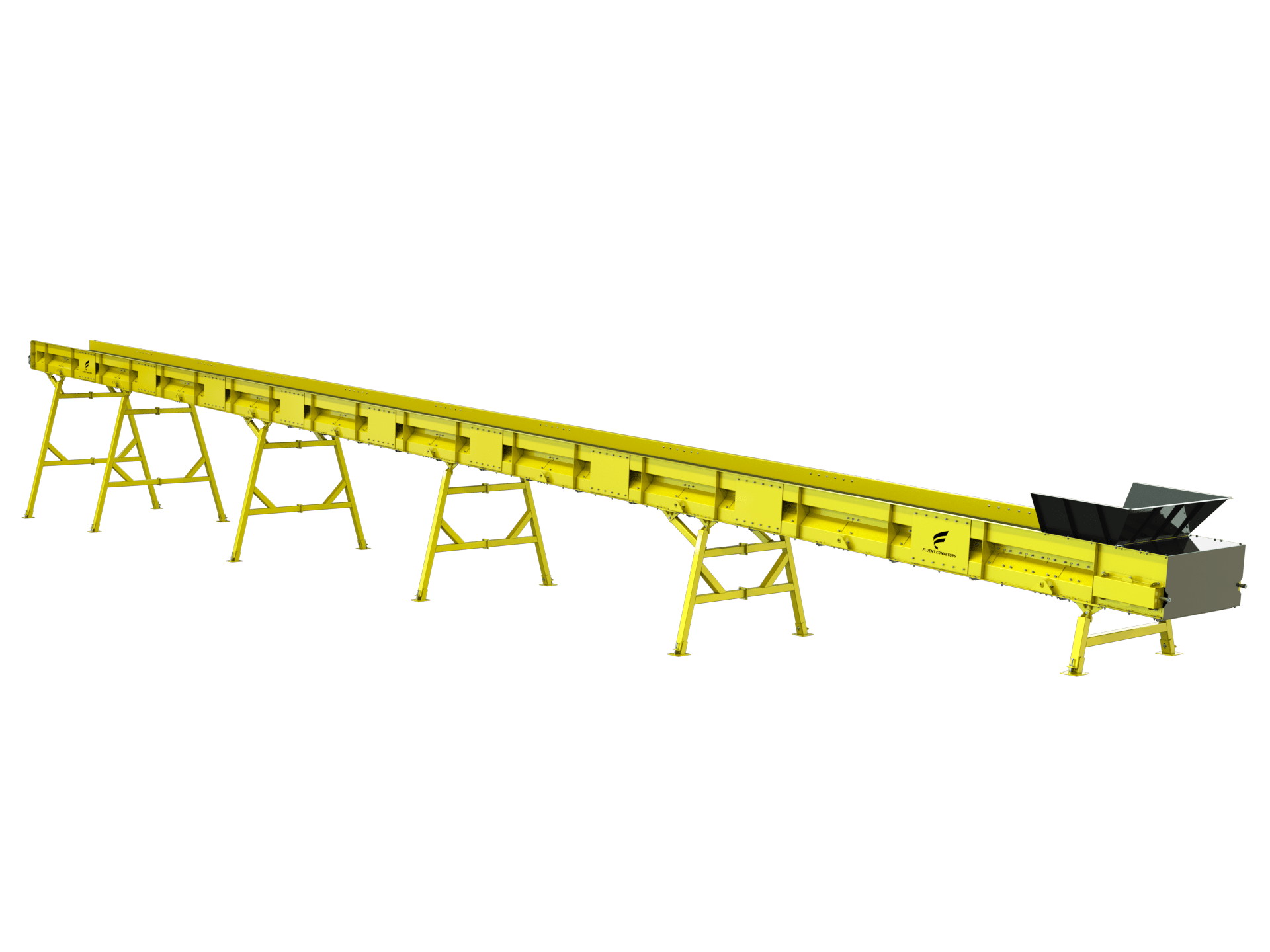

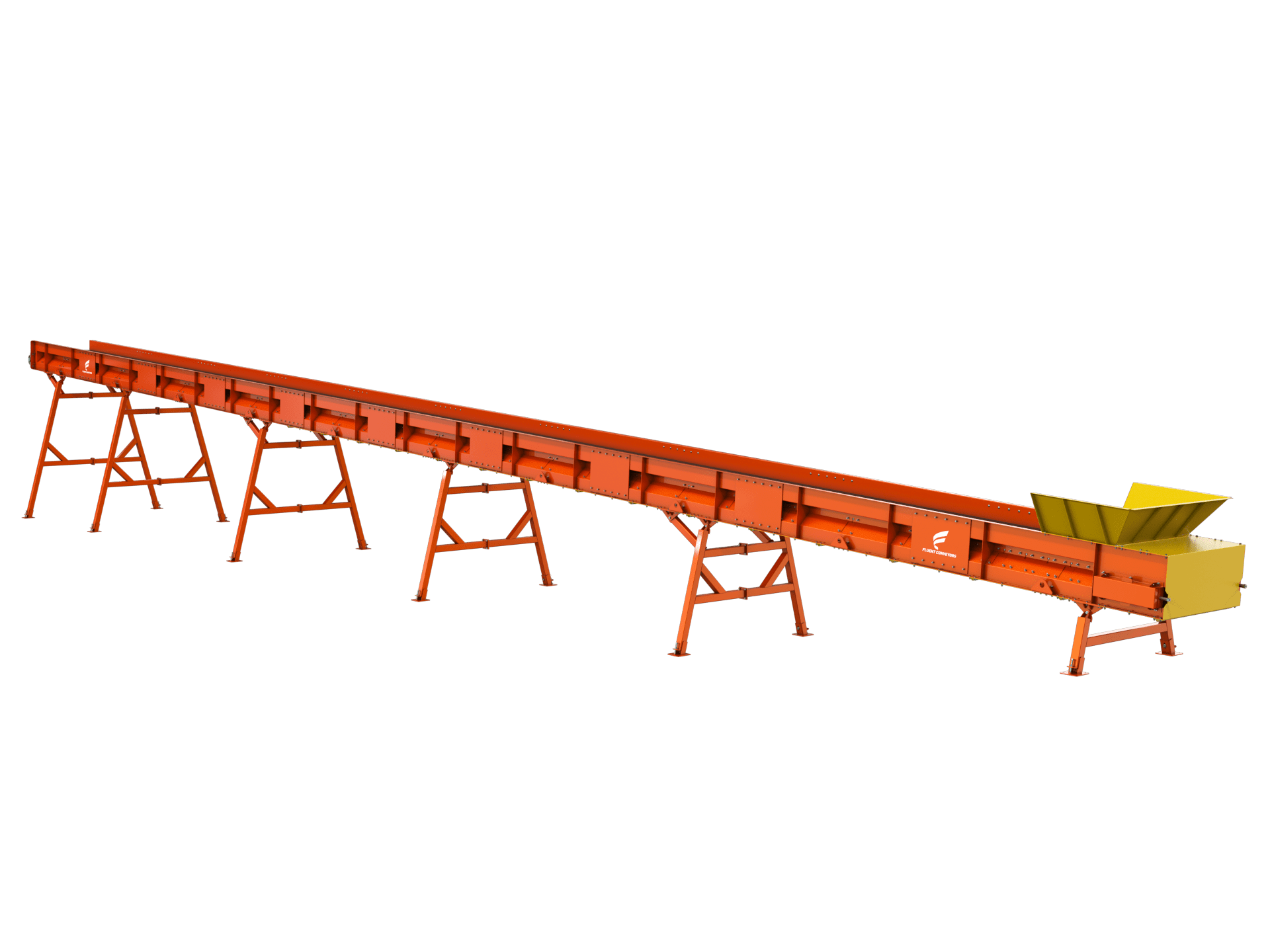

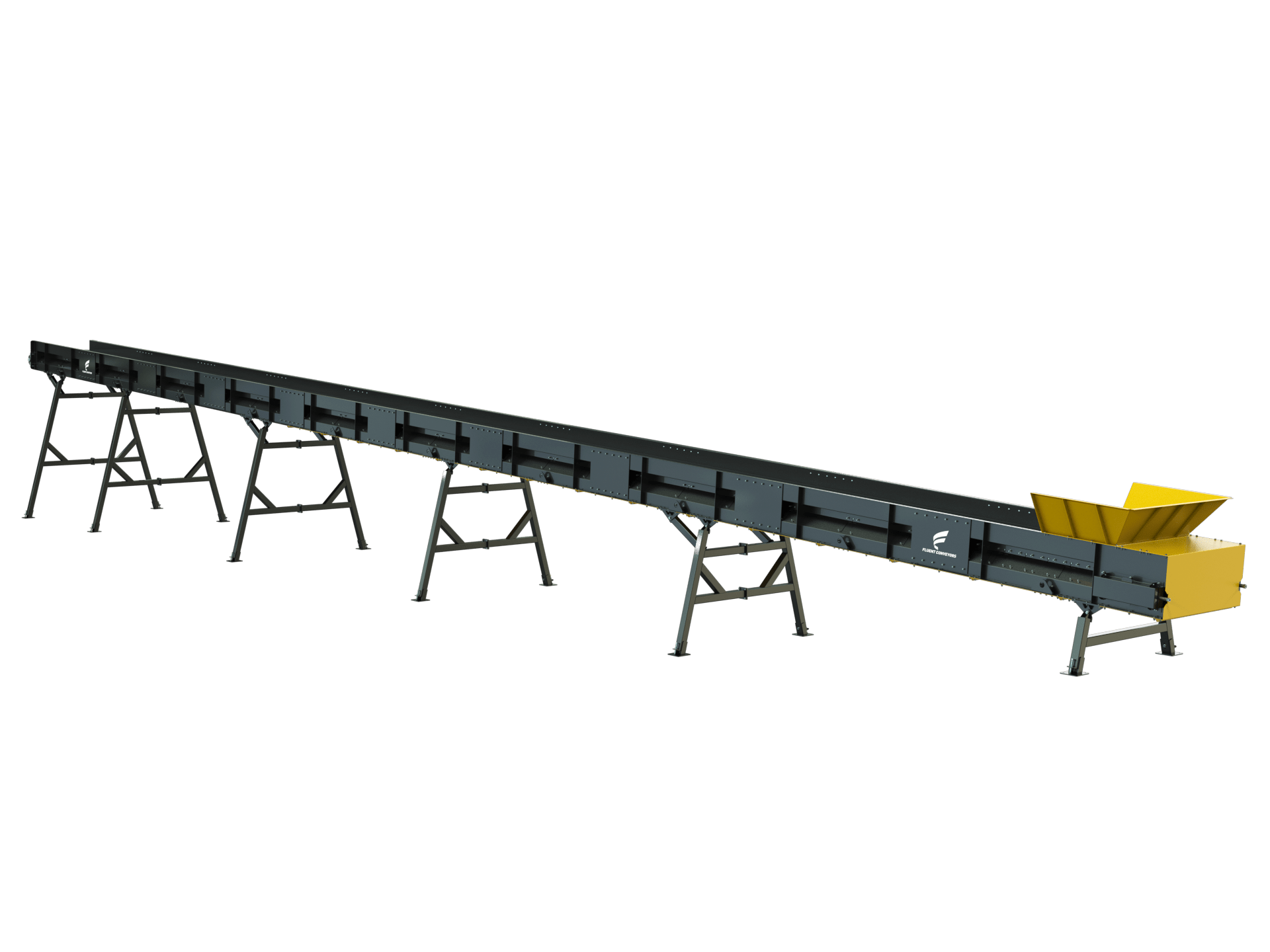

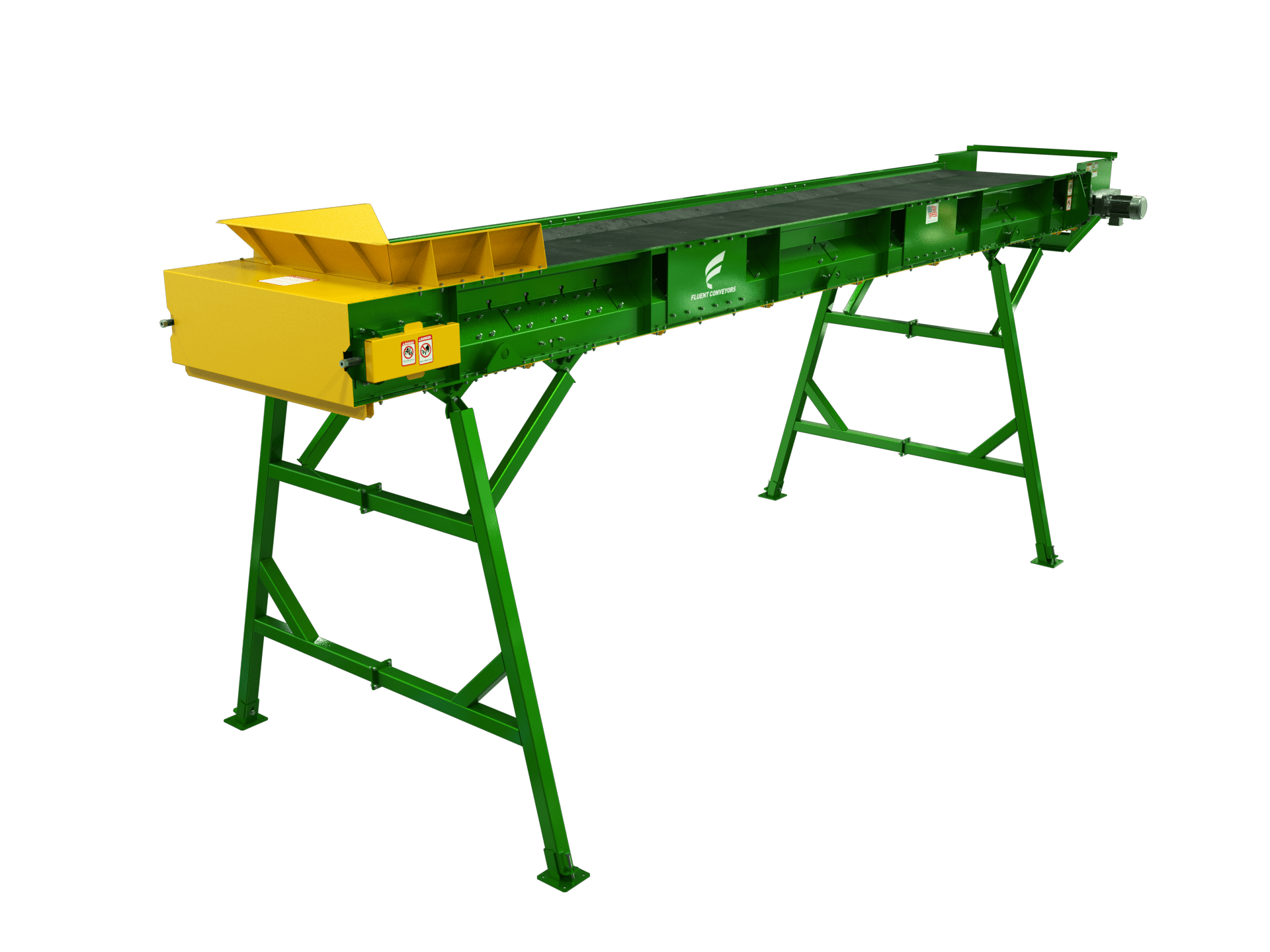

Flat Idler Conveyors

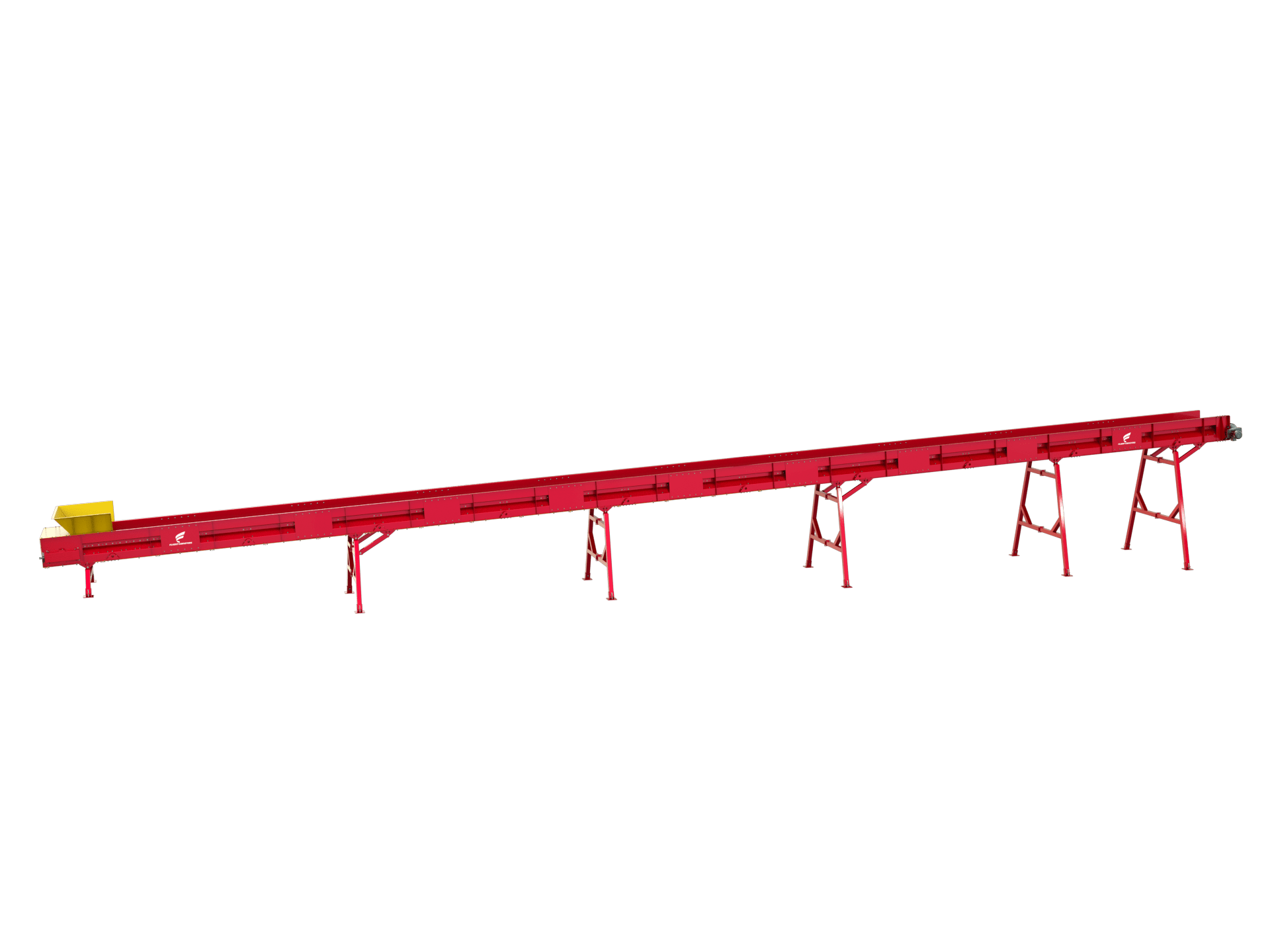

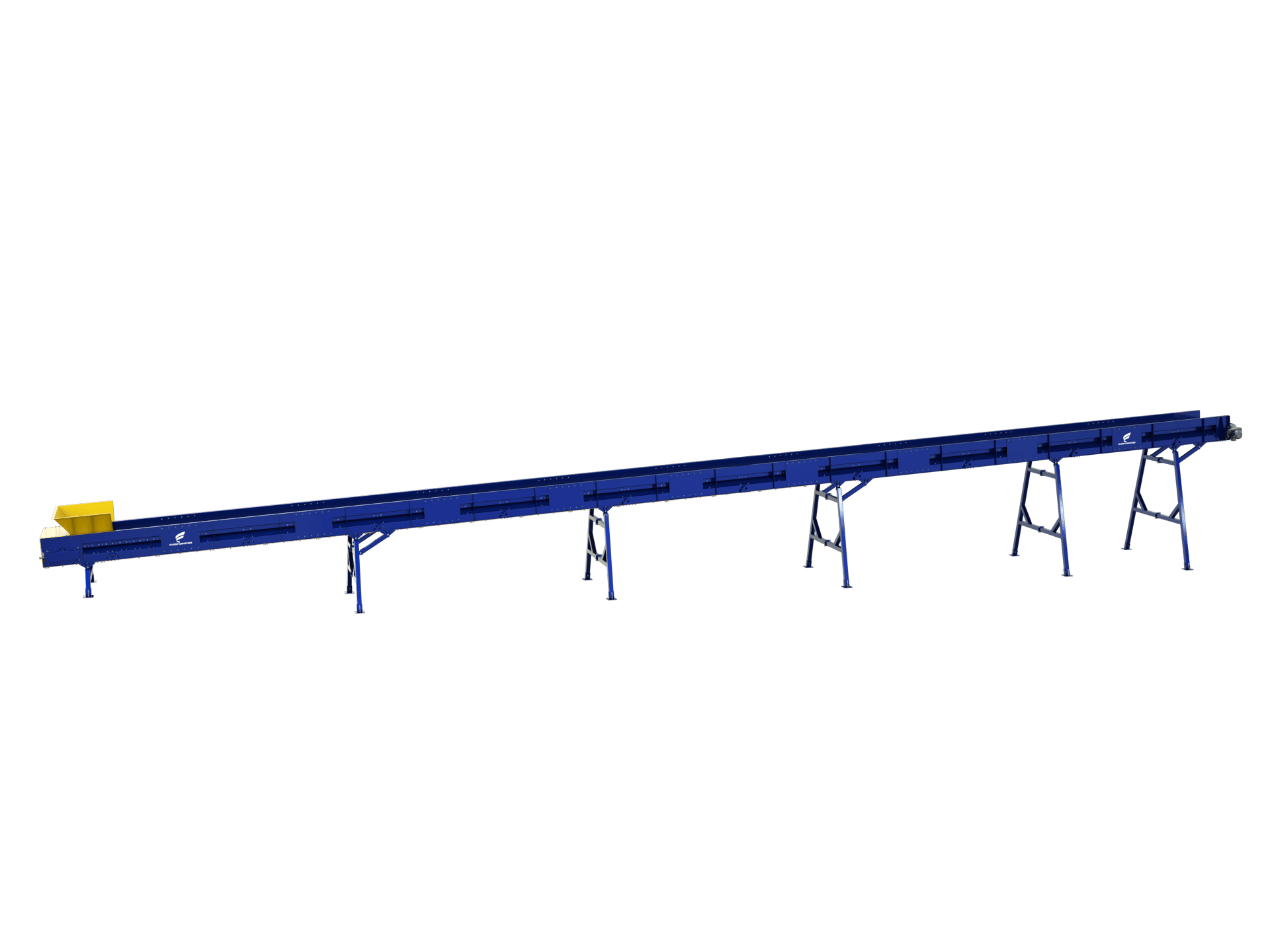

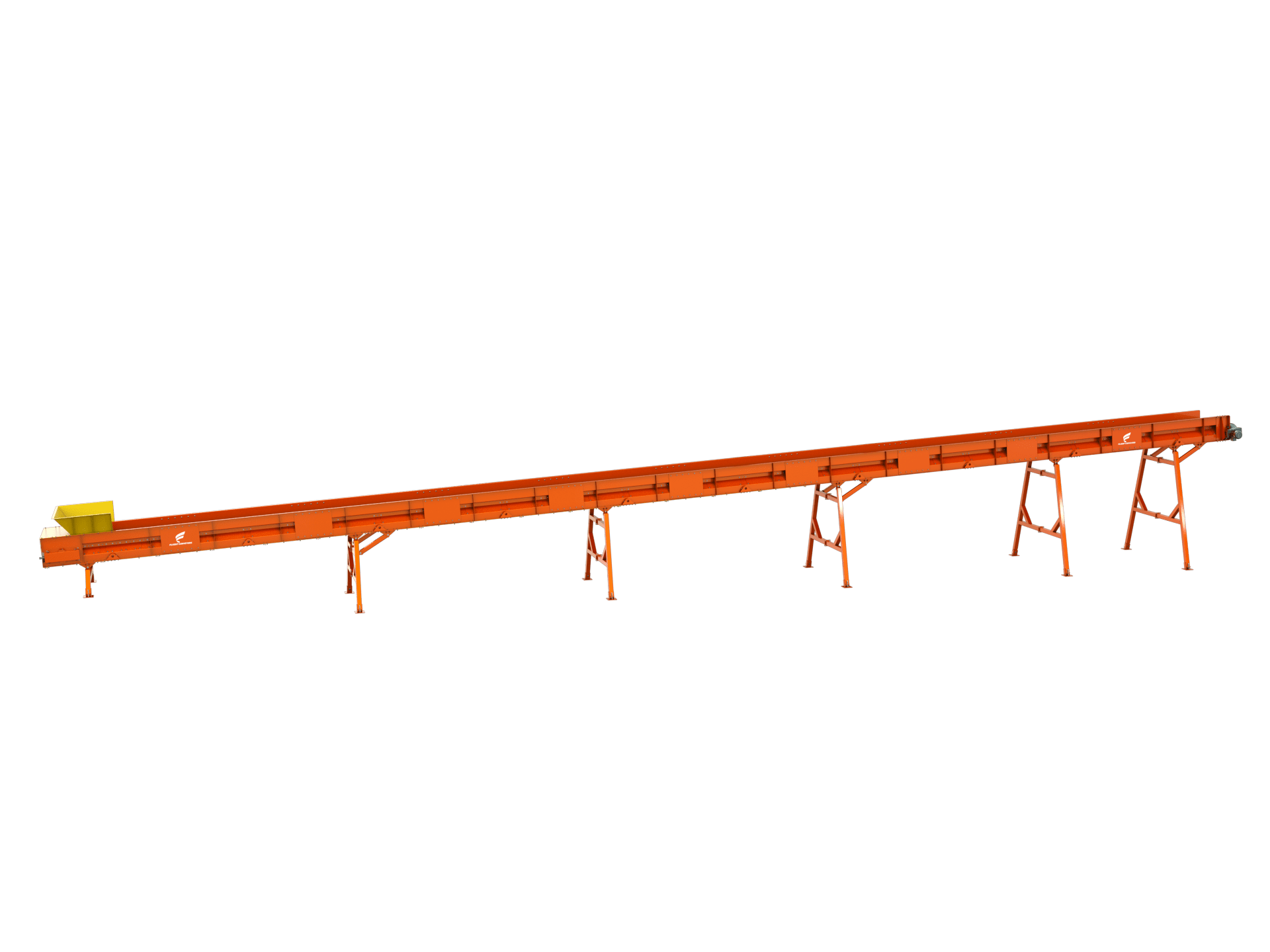

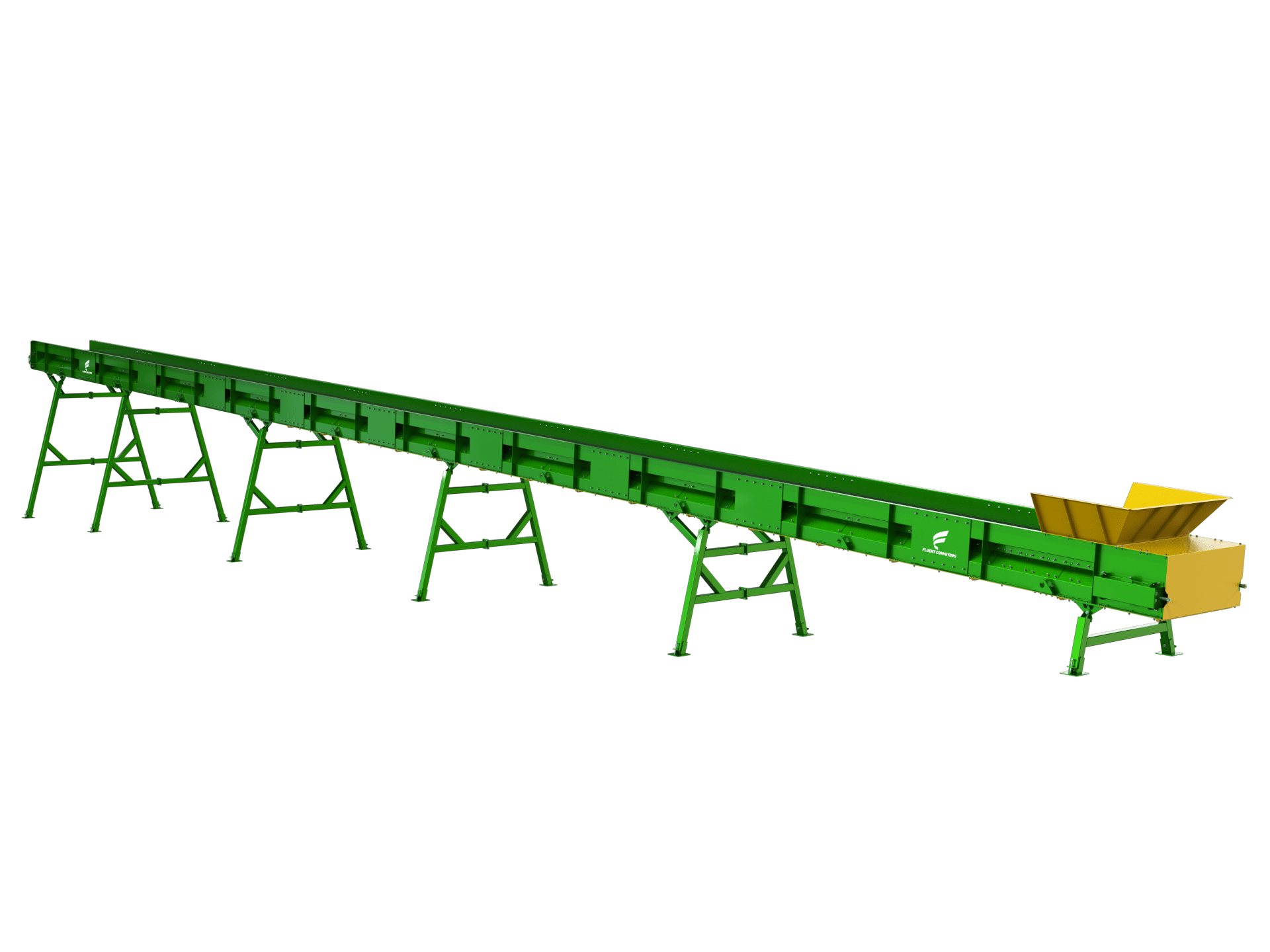

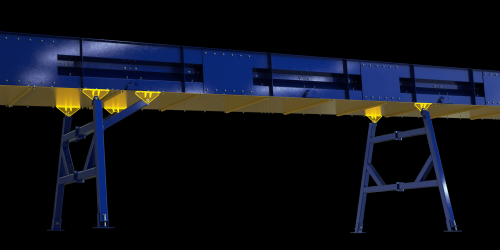

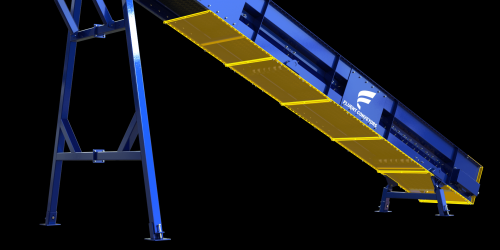

Fluent Conveyors can offer any color required to meet your project specifications. Please let a Fluent Conveyors employee know the RAL number for the paint as well as the paint manufacturer (Sherwin-Williams, PPG, Valspar, Diamond Vogel etc.).

Select Your Color

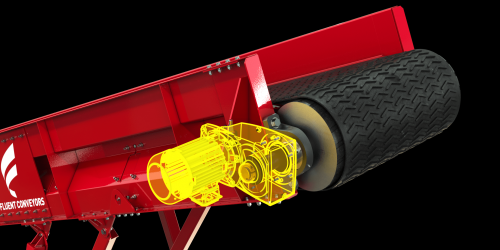

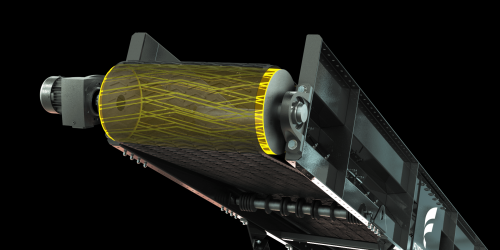

DIRECT SHAFT MOUNTED MOTORS & GEARBOXES:

Fluent Conveyors specs only premium components to complete our equipment and provide a high-quality solution. Fluent Specs Nord Gear Drive units for their quality reputation and exemplary products. Fluent Conveyors can use any specific manufacturer of motors/gearboxes upon request.

COLD ROLLED SHAFTS:

Fluent Shafts are made from cold rolled steel rod and turned to the tightest tolerances in the industry. Every shaft is made custom to fit your specific conveyor.

HEAVY DUTY BEARINGS:

Fluent Conveyors uses bearings that boast cast iron housing, wide inner races providing for larger load capacity than standard duty, B type seals for smooth function and protection against the elements, and the bearings are sized to greatly exceed L10 life hours for the machine load.

FLAME TREATED & HARDENED SPROCKETS:

Fluent Conveyors uses abrasive applications with high shock loading. The inherent strength and flame hardened teeth of these sprockets provide maximum service in the most severe environments. The versatility of flame cut sprockets allows for specialized designs for a variety of customer requirements.

What Customers Are Saying

"In 2019 our manufacturing wood processing facility hit a max processing capacity. We searched around and talked to other conveyor manufacturer companies and was referred to Fluent Conveyors. We had a concept design of a conveyor take would stack piles for cut wood being fed from our trommel screen into numerous 30 foot high piles in a 360 degree radius. Once we contact Fluent Conveyors we knew we found the correct conveyor supplier to help us. Withing 2 weeks we had our fully customized trough pivot conveyor engineered and on order. It has been over a year and our facility has maximized the volume of this system and it has allowed us to grow our bottom line with a 100% increase in our production and a decrease in employee wages. Thank you Fluent Conveyors for taking the time to go on this journey and creating a complete conveyor system for only our application."

-Austin & Jake, San Antonio, TX

Fluent Conveyors offers 6 inch pitch and 9 inch pitch roller chain belts for our heavy duty roller chain model. Core belt offerings include 220 ply and 330 ply rubber combination belts with c-channel backing, 1/4" thick hinged steel pans with optional c-channel, double beaded apron pans and z pan steel belt conveyors.

All belts offer a wide variety of coped cleats, carburized & hardened bushings, chain thickness, pan thickness, cleat spacing, hardened sintered steel rollers, 3" & 4" interlocking side wings and much more to meet a wide variety of recycling & waste processing applications.

**Fluent Conveyors offers 100's of custom belt combitions and options. Please contact our sales team for specific requests

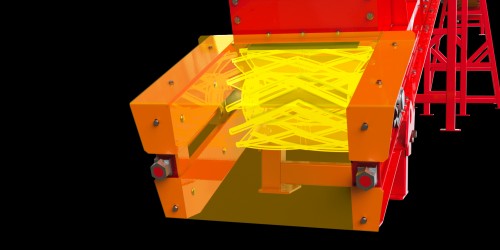

Getting Down & Dirty Pit Roller Chain Conveyor

Your instincts are right... You’re looking at the most robust series of conveyors we offer. Top-of-the-line engineering created with the industry’s highest manufacturing tolerances, our advanced RC Series delivers exactly what the market requires.

The Fluent Roller Chain Series is made to play in the big leagues. Fluent Conveyor’s Pit Infeed Roller Chain Belt Conveyors are found in robust applications and best utilized for new and existing pits.

This model delivers exactly what the market requires for high volume rigid and abrasive material as well as high-temperature and other extreme applications. All designs are made to order and customizable. This model requires 3/8-inch-thick or 1⁄2 -inch-thick pit plates and material is typically fed onto the conveyor with a skid steer, bobcat, front-end loader etc. Only the best machinery, transforming your systems and business.

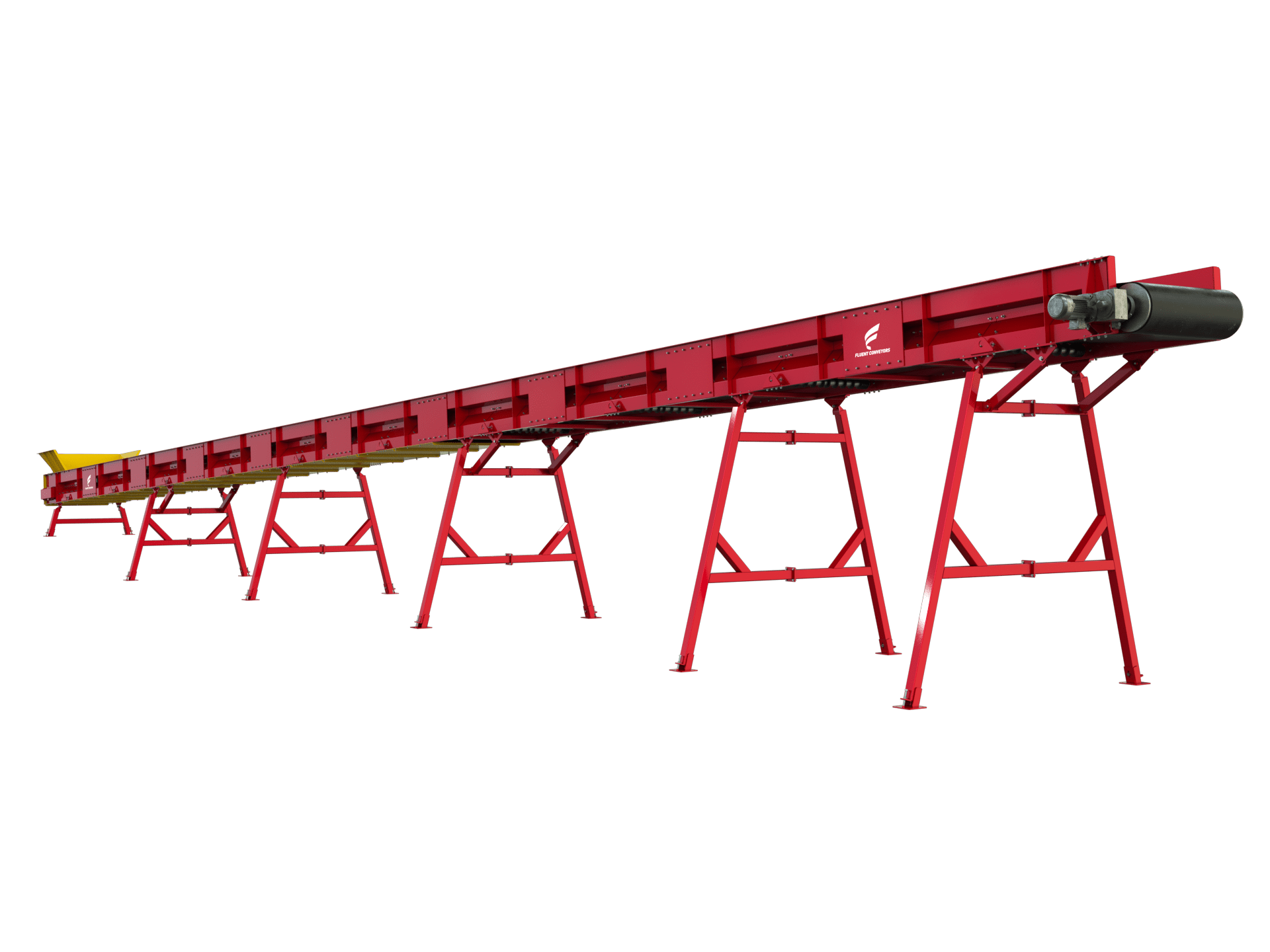

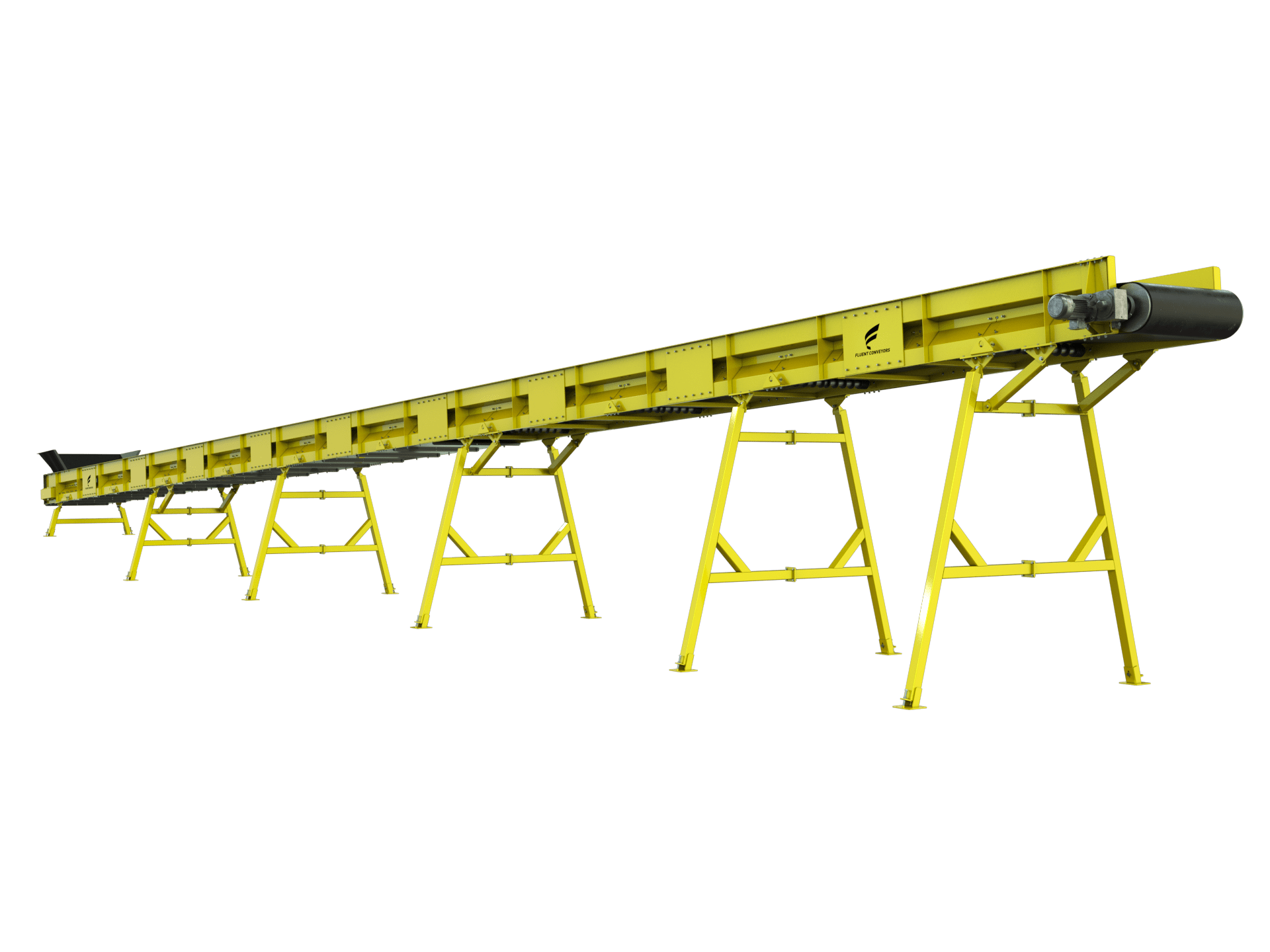

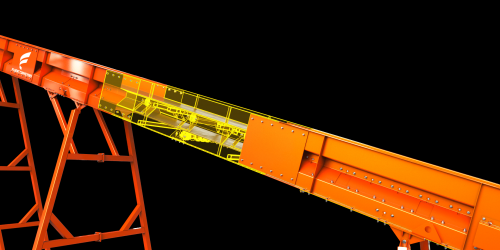

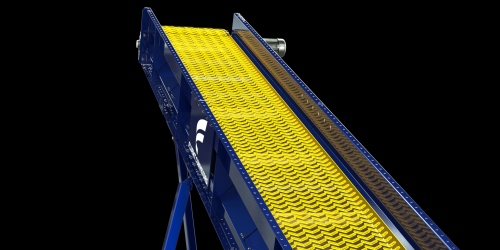

Transfer Roller Chain Belt Conveyor

The Transfer Roller Chain Conveyor ensures smooth operations. It is made to last with easy maintenance, ensuring your system is never lagging.

Fluent Conveyor’s Above Ground Transfer Roller Chain Belt Conveyors are found in robust applications and best utilized to transfer bulk materials spanning long distances and different elevations. This model delivers exactly what the market requires for high volume rigid and abrasive material as well as high-temperature and other extreme applications.

Our conveyors are extremely durable and built for high-performance that stands the test of time. All designs are made to order and customizable. This model is available in inclined, flat, L and S shapes to fit all types of applications. This model primarily used to transfer material from a “feed” conveyor or piece of equipment to another conveyor or piece of equipment.

Uniquely designed to transform your systems into one sleek, seamless operation.

This series of conveyors is the most robust series of conveyors we offer. This model delivers exactly what the market requires for high volume rigid and abrasive material as well as high-temperature and other extreme applications. All designs are made to order and customizable. You will always get the perfect machinery for your unique needs.

Fluent Conveyors is 100% focused on customer safety for all their equipment. This is one of the most important parts of our process. If your team has any internal safety requirements for existing equipment we want to ensure we design our systems to match or exceed those requirements.

We do not authorize removing safety guarding, conveyor safety switches, cords, controls etc. You must consult your local dealer or our engineering department to adjust anything regarding our equipment. If not followed, your warranty becomes void at that time.

Safety offerings include: dead man plates, e-stop / pull cords, protective guarding, manuals etc.

Please Note: The Fluent Conveyors Roller Chain model is extremely powerful and can cause great harm. All maintenance must be performed by a trained and authorized employee or dealer. Before performing any service please lock out / tag out ("Do Not Operate") the electrical inputs to our equipment.

Review CEMA or OSHA to review current safety requirements for conveyors and related equipment.

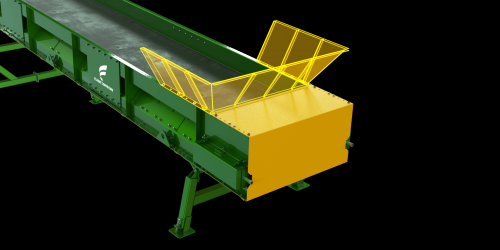

Adjustable Height Supports

Clevis Mount Supports

Bolts on Lifting Lugs

Grade 8 Hardware

Shaft Mounted Motor

Removable Tail Cover

Safety Guarding

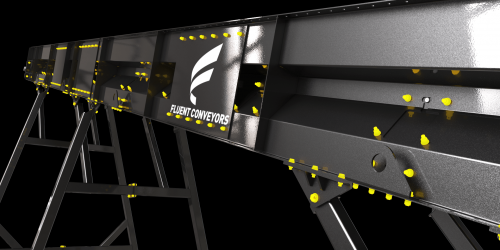

Heavy Duty Formed Frame Sections

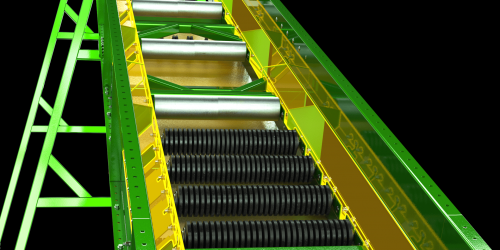

Bolt on Plates of Rollers

Rubber Disc Return Rollers

Return Roller Tracking

Modular Design (to ease modification/relocation/future expansion)

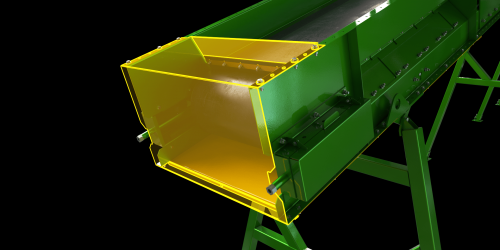

Infeed Hopper

Crowned and Lagged Head

Winged Tail pulley

Heavy duty belting options

Troughed Angled Edges

As well as producing bespoke conveyor systems, we also supply custom replacement belts and parts to ensure no client sees their assembly line stay offline for an extended period of time. From replacement motors to sprockets, everything is covered if a client comes across a failing element of their conveyor system.

Sadly, it’s inevitable your clients will face some type of issue with their conveyor system at some point. Even with Fluent Conveyors’ best equipment in place, conveyors are going to suffer from wear and tear due to their demanding nature. However, being able to offer a solution at any time will be appreciated by your clients.

Are You Ready To Schedule Some Time With The Fluent Conveyors Team? Great!

Our Process Is Typically Very Lean & Detailed! We Prefer Not To Waste Our Customers Time! Engineering Time & Revisions Takes A Considerable Amount of Time For Both Customers & Our Engineering Team.

Please Contact Us If the Roller Chain Conveyor Specifications Match What You Need & You Are Comfortable With:

- Price Can Range From $40,000 - $450,000 Per Conveyor

- Lead Time of 10 – 12 Weeks

- Pre-Payment on Engineering Time if The Project is Complex

- 50% Down-Payment, 40% 2 Weeks Prior To Ship, 10% Net 30 Upon Install